Progreso, a cement company, has achieved a significant milestone in construction technology by completing Guatemala’s very first 3D-printed building. This innovative prototype home has been designed with the resilience to withstand the region’s frequent seismic activity, showcasing a fusion of modern 3D-printing construction techniques with traditional craftsmanship in the form of a thatched roof.

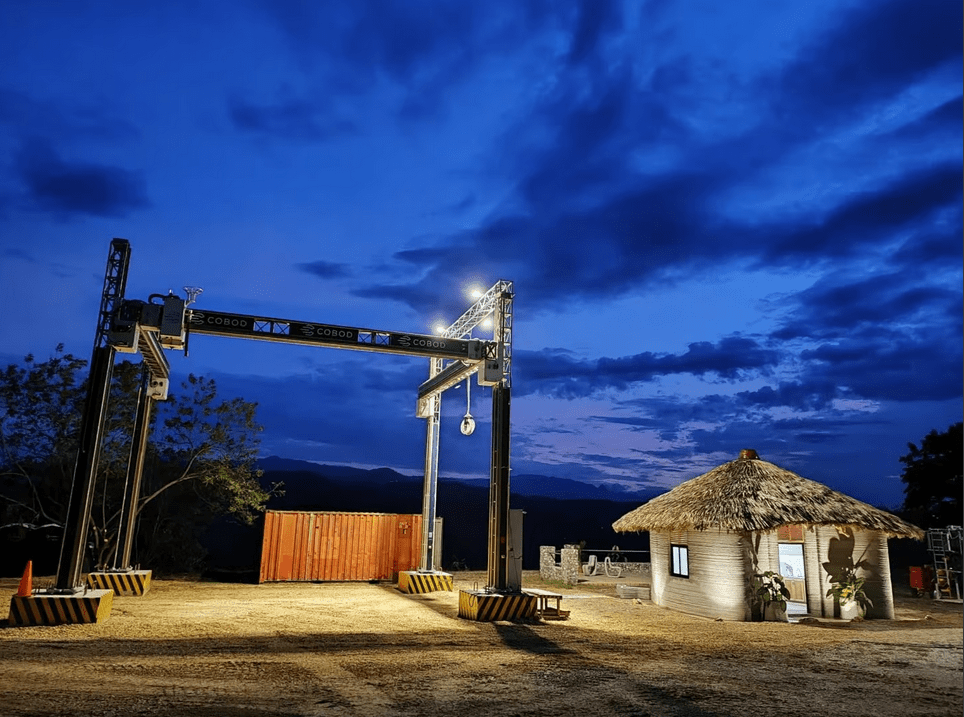

Using COBOD’s BOD2 printer, the same printer employed in the construction of a recent Indian post office and Europe’s inaugural two-story 3D-printed house, the building process closely resembled those previous endeavors. The 3D printer systematically layered a cement-like mixture, meticulously following a predetermined blueprint to gradually construct the building’s shell.

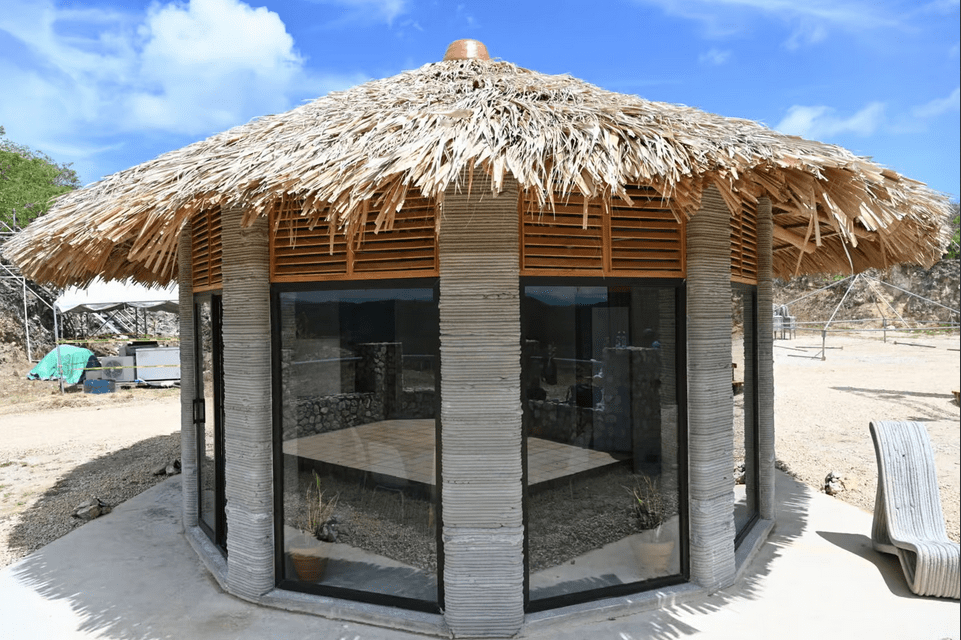

The printing procedure itself took a mere 26 hours, spread out over a week. Subsequently, human workers supplemented the structure with windows, electrical wiring, plumbing, and other essentials, including the distinctive palm-thatched roof, while wooden slats were added for natural ventilation. The emphasis throughout the project was on designing a structure capable of withstanding even the most severe earthquakes.

“The project has successfully taken steps to validate the structural viability of 3D construction printing in a seismic-prone region,” explained the press release. “Due to the use of 3D printing, the house features highly organic-shaped walls that would otherwise be extremely expensive, even unfeasible to complete with concrete blocks, the region’s predominant building material. The 3D-printed concrete walls are complemented by a ‘Rancho’ type palm leaves roof. This roof type has been used for generations in Latin America, as it is inexpensive, provides thermal comfort and is well-suited for seismic regions due to the flexible and lightweight material.”

The resulting house encompasses a floor area of 49 square meters (527 square feet) and features a straightforward, unembellished interior layout that leaves the 3D-printed concrete exposed to underscore its prototype nature. Inside, one finds a central living area equipped with a table and chairs, a compact kitchen area with cabinets and a sink, a room that can function as an office or bedroom, and a bathroom.

It’s important to note that this pioneering project was primarily an exploratory effort, with no immediate plans for large-scale implementation.