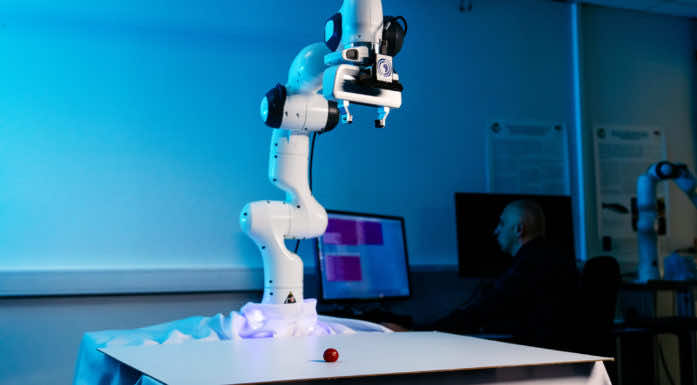

Intelligent food handling by robots can boost productivity and reduce waste in the production chain. Meet the robot with visual and tactile sensing, capable of handling compliant food objects.

Intelligent food handling is one thing that is being tested and tried around the globe. It would reduce the hassle and waste from the production chain. A robot with visual and tactile sensing abilities might be handling your food in a little span of time at your favorite restaurants.

Every year, sadly, a staggering 1.3 billion tonnes of food goes to waste. However, researchers say that this waste of food can be avoided with smart handling of the food. Norway has a population of just 5 million discards a whooping 320,000 tons every year; if this can be prevented, why not give the smart handlers a chance.

Research scientists at SINTEF, a Norwegian research institute, have developed close coordination with stakeholders, both the agriculture and seafood sectors. However, to be useful, robots have to become experts in handling the complex food needed to process items such as meat, fish, and seafood.

“The interaction between a robot and food items that are fragile, soft, and malleable presents us with one of the greatest challenges in the field of robotics today, not least because the materials can change their shape and structure while they are being handled,” says Senior Research Scientist Ekrem Misimi at SINTEF Ocean.

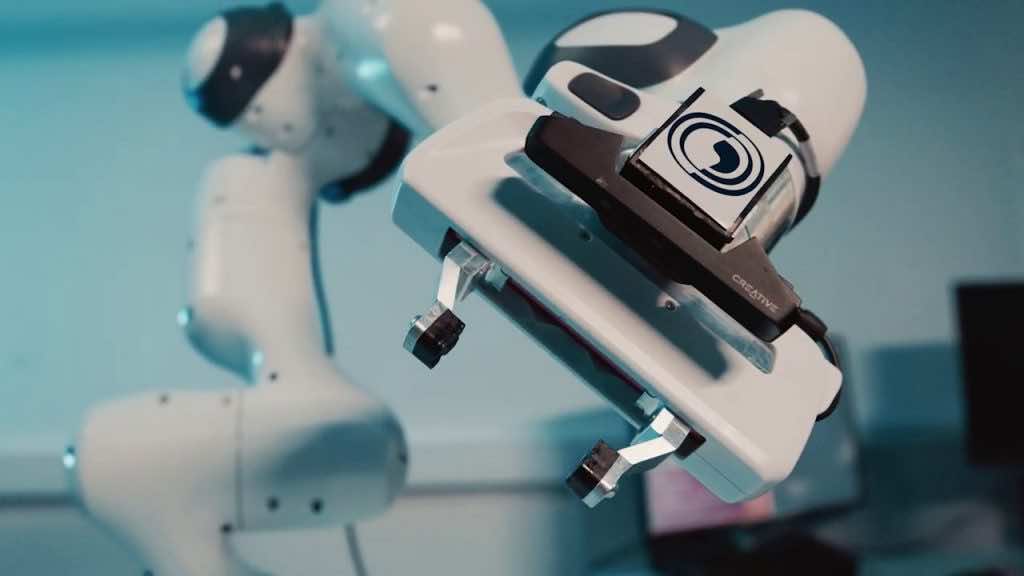

The research team at SINTEF has conceived a robot technology with ‘eyes’ that can see, using 3D vision, an artificial brain sourced by AI. Tactile-sensitive ‘hands’ that can manipulate food items are also a feature of this robot.

“These attributes enable us to teach the robots task-specific intelligence, which is good enough to automatically perform operations such as gripping,” says Misimi. “The robot technology developed as part of this project has succeeded in achieving something that is quite innovative, in that the robot can skilfully handle soft and pliable food items such as fish, vegetables and fruit, that vary in size, shape, and texture,” he says.

“We’ve been developing entirely new concepts and methods that are ideal for small-scale food production systems, which are very common throughout Norway”, says Misimi. “The result will be more flexible and sustainable ways of handling food, leading to better raw materials utilization and enhanced profitability throughout the sector, including small producers. Moreover, robots will also enable us to reduce the need for heavy and monotonous manual labor”, he says.

“Currently, many of the tasks involved in food harvesting and processing are carried out manually,” says Misimi. “These are heavy, demanding, and repetitive jobs that result in wear and tear on workers. If you add to this the mechanical and semi-automatic systems currently in use, which are entirely unable to address the biological variation found in soft food raw materials, we end up with totally inefficient handling and processing, and large volumes of food going to waste”, he says.

Nortura is a major Norwegian food producer and is gladly taking part in the iProcess project.

“They are a problem not least for those who have to carry them out,” says Per Berg, Director of Innovation at Nortura. “So the new technology can be very beneficial, not least from a health and safety perspective”, he says.

“Meat production in Norway is carried out at a relatively small scale when compared with operations in other parts of the world. Even our biggest abattoirs are smaller than most in Denmark and, if we exclude small-scale organic production from certain small-scale farms, operate with only 20 percent of the volumes we see in the biggest Danish slaughterhouses.”

“A robot is capable of gripping and moving food items, but accurate cutting requires practice, precision and a technique that can only be mastered by skilled manual workers”, says Berg.

Currently, Nortura has only a couple robots on its production lines. These are used mainly in connection with automatic placement and sawing. One advantage of robotization is that the meat will not be exposed to bacteria and will have a larger shelf life, decreasing the cost incurred and infectious diseases.

“Our new knowledge and technology are critically important, not only at a time when a growing global population is demanding ever-increasing volumes of protein but also because they will enable us to ensure food production security. This is a function that is key to the well-being of the global community in situations where human operators are prevented from doing their jobs”, says Misimi.

He is hopeful that his team’s research will contribute towards negotiating many of the current hurdles faced by the Norwegian food industry.

“Productivity will increase when the robot’s ‘eyes, ‘brain’ and ‘hands’ are all working together,” says Misimi. “Less food will be discarded, and profitability will increase. In doing so, continued wealth generation will be safeguarded in Norway”, he says. Misimi also believes that flexible robotic automation systems will lend a competitive edge to the European industrial sector.