Although the recent advancements in technology have given rise to the popularity of soft copy, the printing industry has remained resilient, and it continues to grow. In this digital age, it’s easy to underestimate the value of printing machines. Printing papers, products, and packages still remain a powerful and necessary component of many business operations.

Although the recent advancements in technology have given rise to the popularity of soft copy, the printing industry has remained resilient, and it continues to grow. In this digital age, it’s easy to underestimate the value of printing machines. Printing papers, products, and packages still remain a powerful and necessary component of many business operations.

It’s easy to underestimate the value of printing machines (Source: Pixabay)

Continuous inkjet printers (CIJ) is an advanced inkjet technology used in a commercial environment to accurately mark and code a broad array of products and packages. The CIJ technology is highly versatile and can be deployed in a wide range of fields. It can seamlessly handle basic and sophisticated printing tasks. Here’s what you need to know about CIJ printers.

How do CIJ Printers Work?

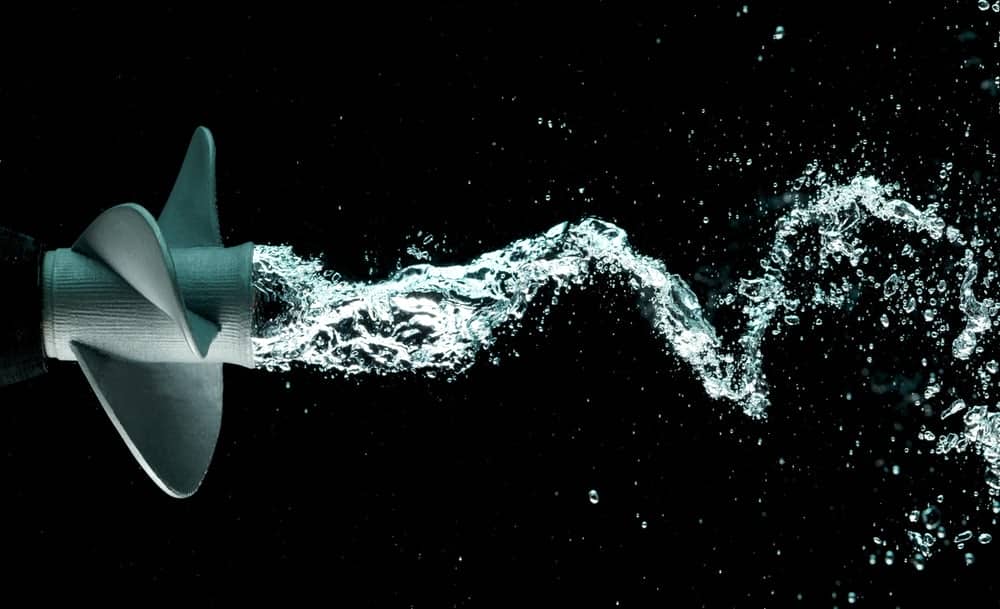

CIJ printers are a non-contact system for applying ink, as noted by Needham Coding. They work by using a high-pressure pump to direct liquid ink, which is stored in a reservoir through a gun body and microscopic nozzle. This generates a continuous stream of ink. An ultrasonic vibration mechanism in the gun body breaks up the liquid into electrically charged tiny droplets at intervals.

The droplets are subjected to an electric field and then transited in a predetermined pattern. They are then accurately applied onto a product via the printhead. Up to 165,000 droplets can be expelled in a second depending on the deflection voltage charge you desire. Any unused droplets are retrieved and transferred to the main tank for reuse.

Actual Applications

CIJ printers are a perfect solution for any industrial environment. They can print on any type of material including paper, packaging film, glass, wood, plastic, and metallic items. They are mostly used to print traceability details onto products and packaging including, manufacturing dates, best before dates, batch codes, serial numbers, and barcodes.

They can also be used to print product names and logos on flat, curved, and textured surfaces. The type of ink you choose depends on the product you want to print or the specific requirements of your industry. Many industries use CIJ printers such as the food and beverage, chemical, cosmetics, cable, pharmaceutical, gadget, and auto industries.

Comparison with Other Printing Methods

CIJ printers have numerous advantages over other printing systems. First, CIJ printers work very fast, making them ideal for high-speed tasks. Second, the ink used dries quickly, minimizing any delays in the line of production. When it comes to operational costs, these printers are more affordable as they don’t require manual operation by a human.

The equipment also requires less maintenance and cleaning as the nozzle isn’t susceptible to clogging, and some have auto cleaning capabilities. Since CIJ printers use a non-contact system, virtually no damage can occur on the product undergoing marking. Also, the printing quality is higher, as the printer is precise. These printers are also able to withstand harsh conditions, and function in any environment whether you are printing for extended periods or just occasionally.

Choosing Your CIJ Printer

There is a lot you need to consider when looking for the ideal printer. Due to the continuous innovations and improvements in CIJ printers, there are now many suitable options available in the market. These range from entry-level, standard to specialist systems like food-grade, small character, heavy pigment, and ultraviolet printers.

There are different grades of CIJ printers (Source: Pixabay)

To get the perfect fit, you need to do your research before making a decision. Some of the things to consider include; the number of text lines you’ll be printing, print height, speed of the printer, the inks you will need, filter life, cost of ownership, ease of use, and eco-friendliness.

Summary

CIJ printers are the perfect option for any product packaging operation. These marking machines are versatile, resilient, and flexible. They can boost the speed of your production line, mark your products with precision, and cut your production cost.