In a world where environmental concerns loom large, Alexander Burton’s ingenious REVR retrofit kit is heralding a new era of eco-conscious driving. Named as the 2023 Australian Dyson Award winner, this transformative technology promises to convert traditional internal combustion engine (ICE) cars into highly efficient hybrids, all in under a day, for a budget-friendly price tag of less than $3,200.

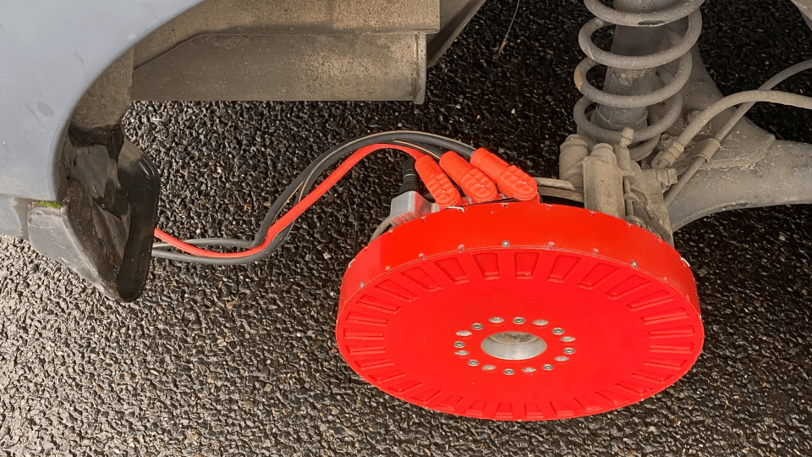

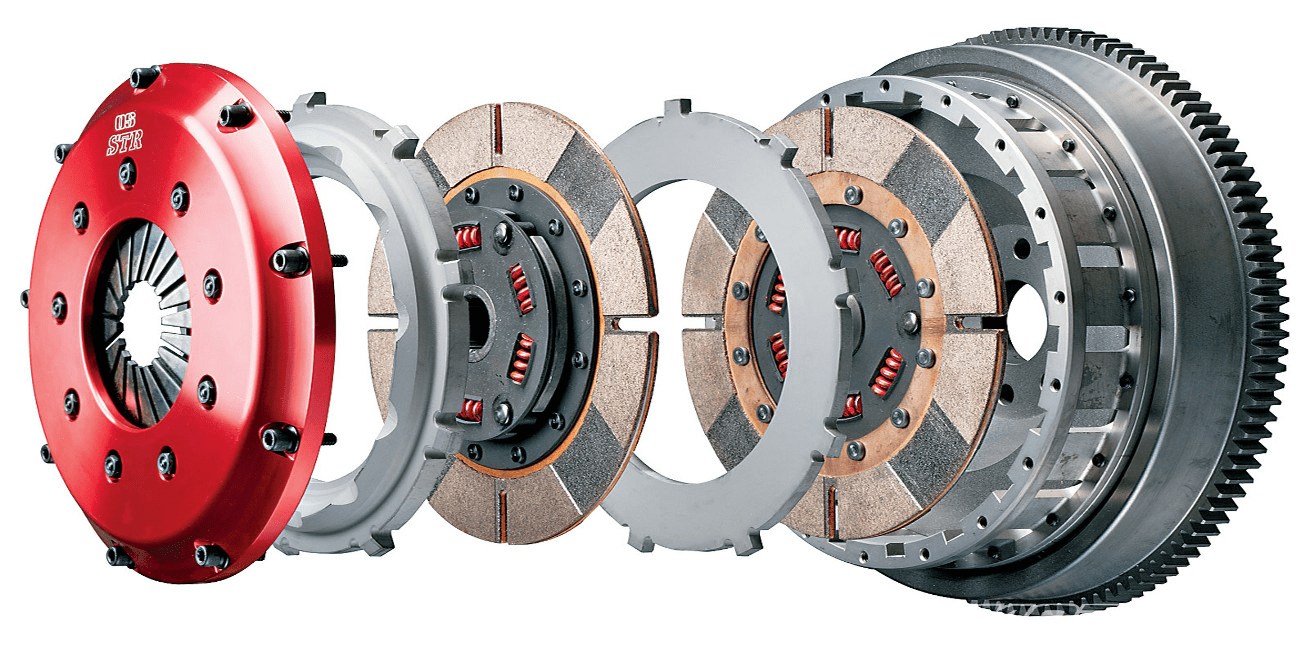

The visionary behind the REVR retrofit kit, Alexander Burton, currently a design student at RMIT University, is rewriting the rules of mobility. At the heart of this innovation lies a flat, power-dense, liquid-cooled 50-kW motor that slots snugly between the wheel and brake disc. It’s a one-of-a-kind pancake-style axial flux motor, sporting a flat stator that bolts onto the wheel hub and a rotor plate delivering torque via the wheel bolts.

While an adapter plate is needed for each car model, Burton has ensured it’s a relatively straightforward process, accessible even to those with limited mechanical expertise. The star of the REVR kit? Its axial-drive electric motor, designed for a seamless, modification-free installation on your wheels.

The trunk well serves as the designated abode for the battery pack and motor controllers, neatly replacing the spare tire. Inspired by the likes of Tesla, Burton’s design makes ample room for a 15-kWh battery pack, providing an all-electric range exceeding 100 km (62 miles) ideal for urban stop-and-start driving. This range comfortably suits the needs of daily commutes. The beauty of the REVR kit is that it can operate in tandem with or independently of the combustion engine, affording drivers flexibility. Plus, a substantial battery pack guarantees 12-V electrics remain operational when the ICE engine is idle, ensuring functions like headlights and air conditioning aren’t compromised.

Fine-tuning of the accelerator pedal integration is still underway. Burton’s plan involves the use of a potentiometer or a similar device to read the accelerator input, facilitating both acceleration and regenerative braking – a familiar feature in hybrid vehicles. Traditional hydraulic braking remains untouched and at your service. An essential feature to implement is switching off the electric motor or engaging in reverse mode when needed.

Concerning a battery-level display, Burton suggests that basic REVR conversions won’t come equipped with one. Instead, diagnostics can be conveniently accessed through a smartphone, maintaining simplicity as a core principle.

Burton’s ambition is to bestow the retrofit with a zero carbon footprint. Initially, the focus will center on around 20% of the most popular car models, with the Corolla, Accord, and Civic groups being among the first in line. Burton is open to partnerships and new avenues for REVR. The ultimate mission? Transform one million cars. The anticipated price for a fully installed dual-motor, 15-kWh kit is a budget-friendly 5,000 (US$3,200) – a cost Burton believes can further decrease with widespread adoption and falling material prices, possibly reaching under 10,000 (US$5,400).

Addressing the legality of this innovative transformation, Burton acknowledges the need to navigate specific regulations but remains optimistic that updated legislation will accommodate it. In-house engineering certification may be the key to meeting any regulatory requirements.

In a personal commitment to his creation, Burton plans to convert his own 2001 Corolla in the coming months, with plans to make the retrofit kit available for purchase in the third quarter of the following year. REVR boasts a pending patent, already attracting significant interest from potential investors and crowdfunding opportunities. While the primary focus is the Corolla conversion, REVR remains open to exploring partnerships and additional avenues for growth. The ambitious stretch goal is to convert one million cars.

Despite the substantial increase in torque, Burton doesn’t view the REVR retrofit as a performance enhancement. Safety considerations prevail. Yet, as the project advances, Burton envisions expanding the system’s capabilities to the point where users can entirely remove their engines, embracing the entire electric operation. While a complete electric conversion with a larger battery pack might be pricier, the modular and minimalist structure of the REVR kit keeps it affordable compared to traditional EV conversions.

At its core, the REVR retrofit is a beacon of hope for those seeking a swift, uncomplicated, and cost-effective path to reduce their carbon footprint – an alternative to investing in a costly new electric or hybrid vehicle. It’s an idea that carries immense promise, albeit with challenges. The journey of this extraordinary project is one that many eagerly anticipate.