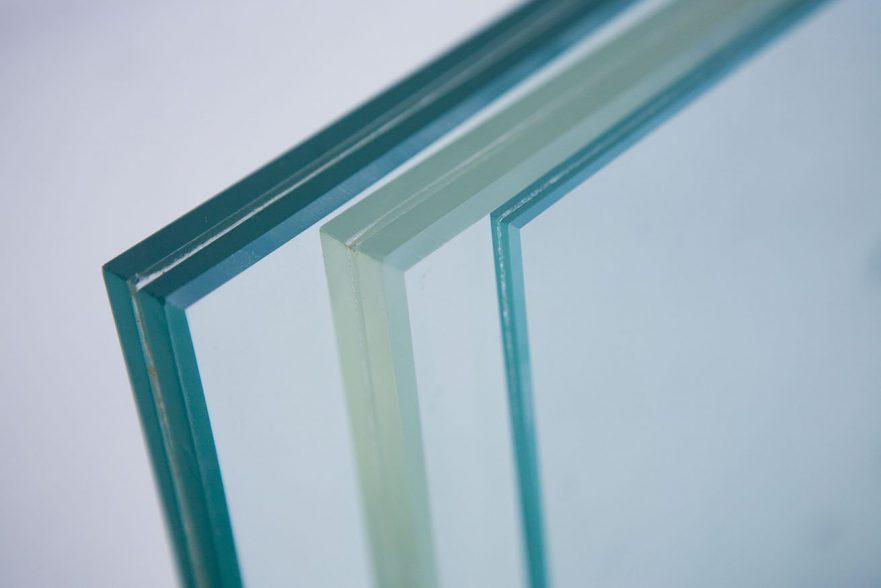

With the creation of LionGlass, a new kind of glass that is not only 10 times more damage resistant but also consumes a great deal less energy during production, engineers at Penn State made a revolutionary advancement in the field of glass manufacturing. Glass has always been troubled by its innate brittleness despite its many benefits. However, LionGlass asserts that it will transform the sector. The production of soda lime silicate glass, the most popular type of glass, is not environmentally beneficial. High-temperature furnaces used in its manufacturing process use a lot of energy and emit a lot of carbon dioxide into the atmosphere. In addition, when the raw materials are melted, such as soda ash, limestone, and quartz sand, they release CO2.

To address these issues, Penn State researchers have improved the glass recipe by replacing soda ash and limestone with aluminium oxide or an iron compound. This substitution not only reduces direct emissions during melting but also lowers the required temperatures by up to 400 °C (720 °F), resulting in a 30% decrease in energy consumption and emissions.

In addition to being more eco-friendly, LionGlass exhibits remarkable strength. Tests conducted on the glass showed crack resistance at least 10 times higher than that of standard soda lime glass. Even under a force-load of 1 kg (2.2 lb), LionGlass did not crack, while regular glass typically cracks under a load as low as 0.1 kg (0.2 lb).

The benefits of LionGlass extend beyond its enhanced strength. Due to its higher resistance, products made from LionGlass can be thinner and lighter. This reduction in weight translates to reduced raw material usage, lower energy requirements for production, and decreased transportation energy. Consequently, LionGlass is a win-win situation for both the environment and consumers. The team at Penn State has filed a patent for LionGlass and aims to bring this remarkable material to the market in the near future. With its superior strength, lower energy consumption, and environmental benefits, LionGlass has the potential to revolutionize various industries, from construction to automotive and beyond. The future looks bright for this innovative glass technology.