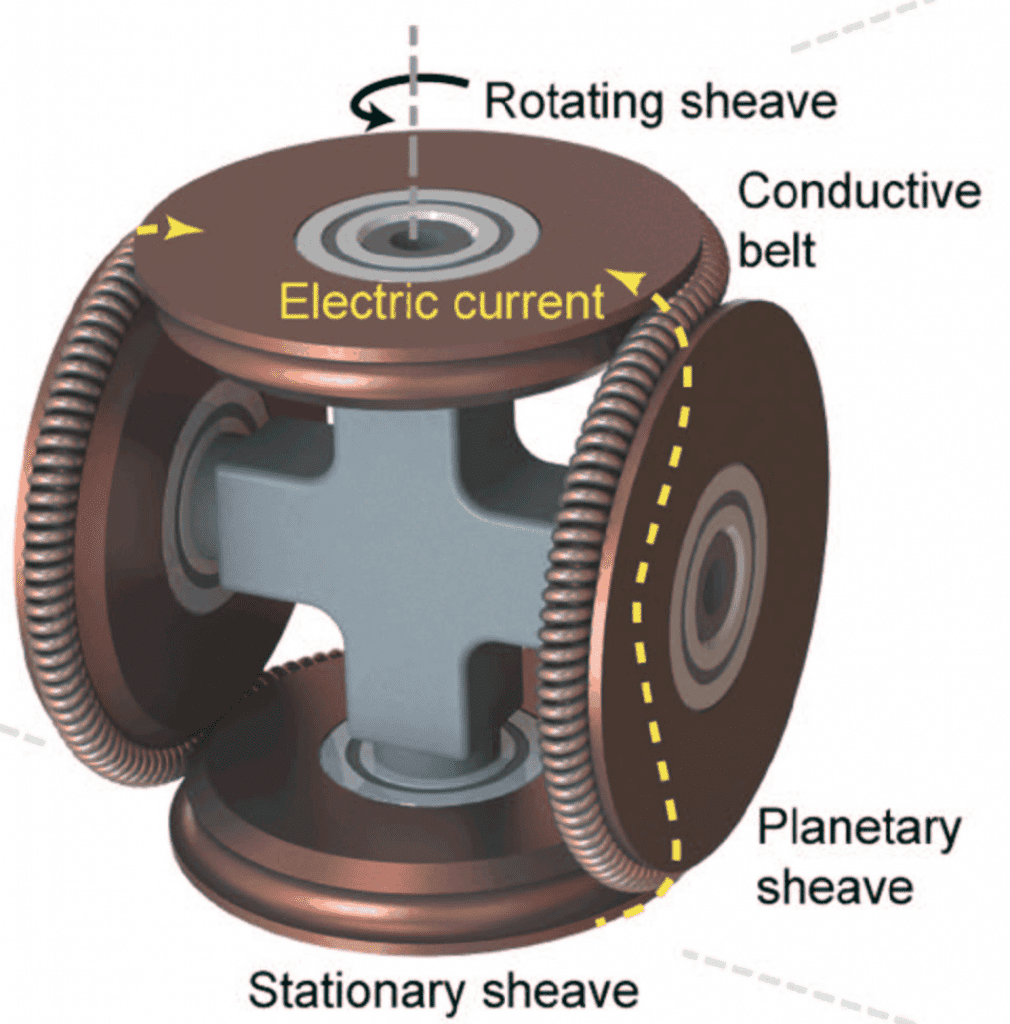

Today we are talking about a novel and effective way to generate electricity through wind turbines. Researchers from Sandia National Laboratories have stepped up to develop an incredibly seamless rotary electrical contact technology for wind turbines that would drastically reduce operating costs. The new technology named “Twistact” will ultimately substitute expensive rare-earth magnets and will substantially lower the maintenance costs as well. Moreover, the system is sustainable and has the capacity to remain in service for a whopping 30 years without any requirements for replacing or maintaining it.

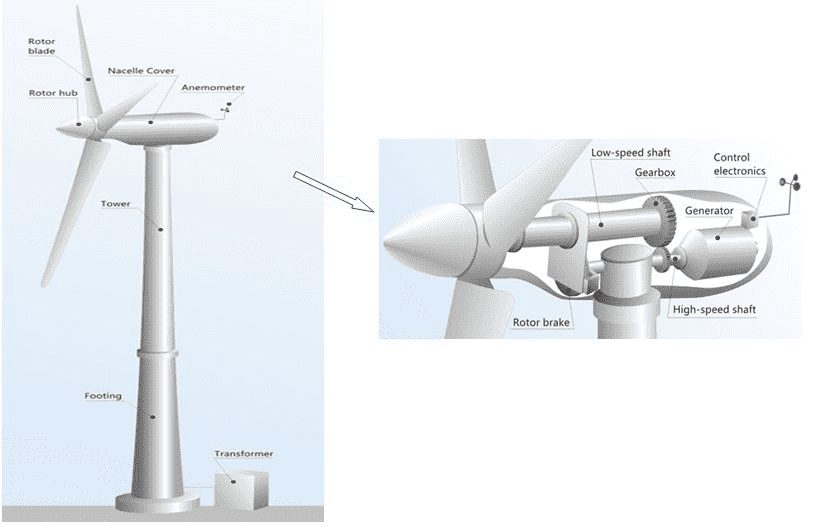

At the heart of the innovation is its effective approach to smoothly transmitting electrical current within two rotating assemblies of wind turbines, specifically between the stationary and rotating frame. Furthermore, transmitting electric current through an ultra-low resistive pathway proves a cherry on top along with extremely low costs as compared to the previous method utilized in wind turbines. As per the company, due to the excessive maintenance of slip rings or brushes of the wind turbines, the entire system could become less operative and its performance deters over time. This may lead to high maintenance costs and rapid replacement issues.

According to Jeff Koplow, who works at Sandia as a research scientist and engineer, “We knew it would be game-changing if we could find a way to get around the limited-service lifetime of conventional rotary electrical contacts. We spent a lot of time considering if there was another plausible way to develop a rotary electrical contact architecture.” However, the most interesting thing to note about this technology is that companies in California have started to deploy Twistact technology in their vertical wind turbines. Hence, the use of this technology against brush or rings could change the landscape of the concept of generating electricity through wind turbines.

To that end, we know how expensive these rare-earth metals are and how difficult it would become at times to maintain them. You might have heard of the issues arising in the supply of these materials i.e., Neodymium and Dysprosium in 2011 due to their expensive nature and how badly they affected the whole industry. Hence, it is always advisable to bring about a sustainable and efficient technology having lower costs so that it could benefit in the future. And that’s what Twistact is all about!