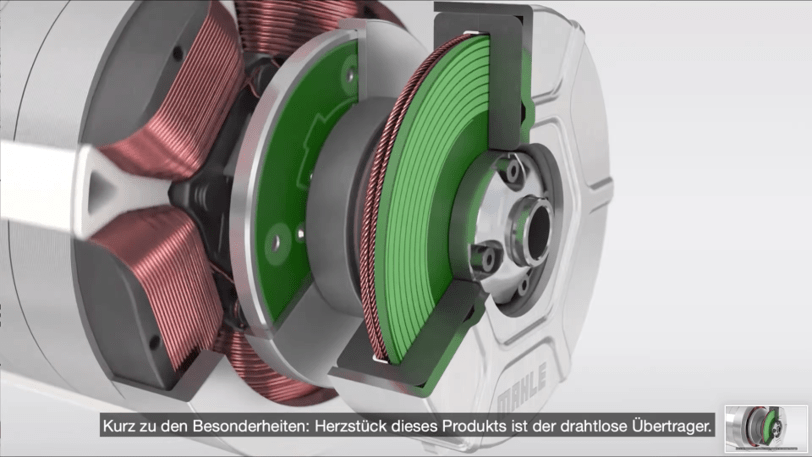

The electric vehicle (EV) industry is at the forefront of innovation in a world that is racing towards sustainable mobility. Companies worldwide are fervently exploring ways to perfect magnet-free electric motors, and among them, ZF Friedrichshafen stands out with its revolutionary approach. Taking inspiration from the wireless inductive path trodden by fellow German automotive supplier Mahle, ZF has carved its own distinctive niche. By ingeniously embedding its inductive transmitter within the rotor itself, ZF has conserved valuable space and birthed an extraordinarily compact, magnet-free motor that promises to rival the performance of conventional permanent-magnet synchronous motors (PSMs).

In the pursuit of cleaner and greener EV propulsion, the elimination of magnets from a motor’s rotor, replaced by electrical windings, has emerged as a beacon of hope. This shift helps eradicate the exorbitant costs and environmental concerns associated with rare-earth material mining and addresses potential supply chain vulnerabilities. However, the traditional magnet-free designs have their own set of challenges, primarily introducing cumbersome physical elements like sliding rings or brushes to facilitate electrical current flow into the rotor windings. This increases size and weight and raises concerns about friction and wear and tear. Understandably, EV manufacturers have often opted for the path of least resistance, gravitating towards permanent-magnet motors.

Enter contactless induction, a promising solution that delivers electricity to rotor coils without the need for physical brushes or rings, effectively nullifying these drawbacks. ZF has taken a giant leap forward by seamlessly integrating its inductive transmitter deep within the rotor shaft, nestled at the heart of the coils. This ingenious innovation obliterates the additional 3.5 inches (90 mm) of axial space typically consumed by conventional solutions such as brushes. Remarkably, it manages to offer power and torque density on par with PSMs, ushering in a new era of compact efficiency.

This groundbreaking design christened the “In-Rotor Inductive Excited Synchronous Motor (I2SM)” holds the tantalizing promise that automakers can now make a seamless transition from PSMs to this innovative motor without any compromise in terms of packaging or performance. ZF boldly asserts that, during continuous high-speed operations such as highway cruising, the I2SM surpasses the efficiency of a PSM.

When it comes to size, ZF’s inductive transmitter appears to outshine alternatives like Mahle’s design, which relies on two larger-diameter discs enveloping the rotor shaft’s exterior. However, a word of caution: making definitive comparisons or fully substantiating ZF’s claim of possessing the “world’s most compact and torque-dense e-motor without magnets or rare earths” based solely on preliminary illustrations is a task best left for future concrete specifications. These specifications, encompassing dimensions, weight, and output figures, are eagerly awaited to evaluate this groundbreaking technology conclusively.

Currently, ZF is firmly committed to the relentless pursuit of production readiness. Their mission is to seamlessly integrate I2SM units into 400-V and 800-V electric drive platforms, catering to the demands of passenger car and commercial vehicle manufacturers alike.

ZF unveiled its initial strides in I2SM technology at the recent IAA Mobility Munich show, setting a definitive course for the future of electrified automotive propulsion.

Source: ZF Friedrichshafen