Vestas, the renewable energy company, has expanded into robotics with the introduction of BladeRobots, a new standalone firm, according to a press release.

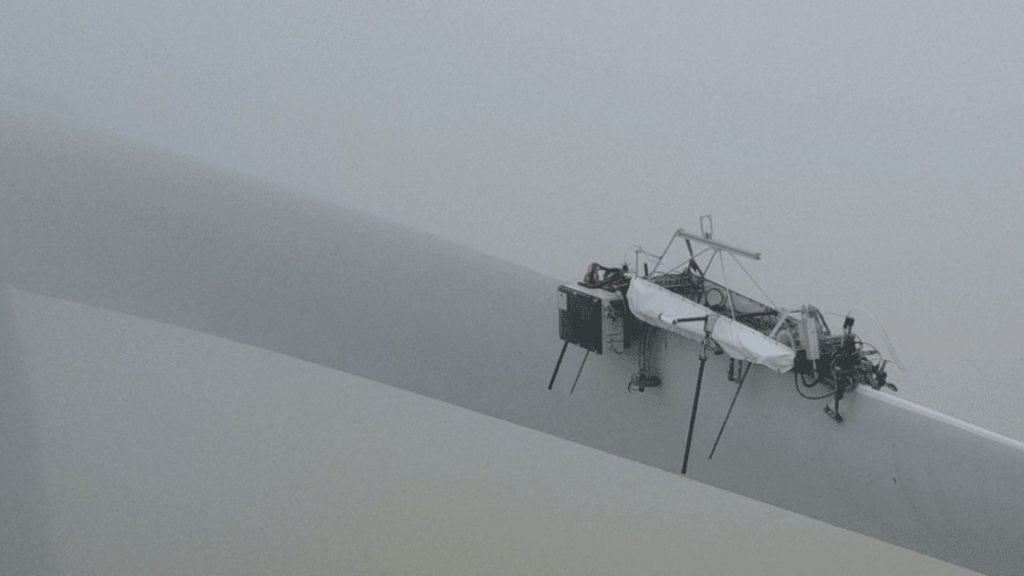

The business, which was incubated within Vestas, has been set up to bring out a robotic technology that automates wind turbine blade edge maintenance.

“Wind energy will play an increasingly central role in the global energy system, and it is key that we deliver optimal efficiency throughout the operational life of wind turbines,” said Johnny Thomsen, chairman of BladeRobots and former co-chief executive of MHI Vestas Offshore Wind.

“With BladeRobots’ automated robotic solution, the wind industry has a new effective and scalable solution to improve wind turbine performance.”

Vestas claims that BladeRobots provides a unique technology that performs automated blade-leading edge maintenance up to four times faster than traditional manual methods. This leads to a highly scalable, cost-effective solution that raises safety standards for the specialists involved and increases wind turbine annual energy production by restoring aerodynamic performance and reducing turbine downtime.

Artificial intelligence is used by the robotic solution to instantly adapt to any industry blade.

A Danish company, Skagen Blade Technology ApS, has decided to invest in BladeRobots as a minority shareholder.

Vestas Ventures, Vestas’ corporate venture capital arm, will own a majority stake in the company.