We have been talking about 3D printing and what it has helped us accomplish in such a short time. The reason for that is simple; this technology is convenient and its marvelous. The ease and the freedom it provides to the user is far beyond what we had hoped for. Today’s post is about a 3D printed computer which is hand-cranked. Hackerspace NYC Resistor organized a ‘digital archaeology’ show that was basically an interactive show last spring and it was there that Chris Fenton, an electrical engineer, exhibited his skills.

We have been talking about 3D printing and what it has helped us accomplish in such a short time. The reason for that is simple; this technology is convenient and its marvelous. The ease and the freedom it provides to the user is far beyond what we had hoped for. Today’s post is about a 3D printed computer which is hand-cranked. Hackerspace NYC Resistor organized a ‘digital archaeology’ show that was basically an interactive show last spring and it was there that Chris Fenton, an electrical engineer, exhibited his skills.

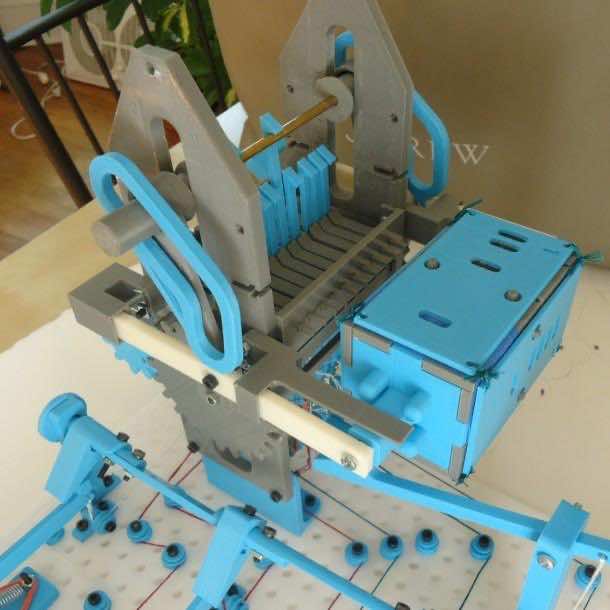

Chris usually works with supercomputers but he wanted to take it to a smaller level and that is when he decided to build a throwback computer; a Turbo Entabulator, which took him around 50 hours to build. This 3D printed computer makes use of punch cards, rubber bands and strings to perform functions. If you crank it for a minute it will generate part of the Fibonacci sequence, the numerical pattern which can be seen in nature. The machine itself isn’t very useful, but the way it has been constructed has given it the due amount of fame.

Chris usually works with supercomputers but he wanted to take it to a smaller level and that is when he decided to build a throwback computer; a Turbo Entabulator, which took him around 50 hours to build. This 3D printed computer makes use of punch cards, rubber bands and strings to perform functions. If you crank it for a minute it will generate part of the Fibonacci sequence, the numerical pattern which can be seen in nature. The machine itself isn’t very useful, but the way it has been constructed has given it the due amount of fame.

The crank computer costs around $100 and comes with three distinct stages; software, memory and processing. The punch cards that are employed, work like software for this computer. The cards basically start a motion of levers that are responsible for pulling strings and finally increase/decrease numbers on the counters. In order to ensure that these cars run without a break, they are tied together with loops of embroidery floss. The counter wheels act like RAM when they store numbers that are being generated by the counters. The hand crank is the CPU for our computer, the faster it is turned the faster the computation occurs. An amazing work of art, isn’t it?

The crank computer costs around $100 and comes with three distinct stages; software, memory and processing. The punch cards that are employed, work like software for this computer. The cards basically start a motion of levers that are responsible for pulling strings and finally increase/decrease numbers on the counters. In order to ensure that these cars run without a break, they are tied together with loops of embroidery floss. The counter wheels act like RAM when they store numbers that are being generated by the counters. The hand crank is the CPU for our computer, the faster it is turned the faster the computation occurs. An amazing work of art, isn’t it?