A team of South Korean researchers has created the world’s first hydrogen-powered plasma torch capable of breaking down unsorted plastic waste into valuable raw chemicals at extreme temperatures of up to 2,000°C (3,600°F).

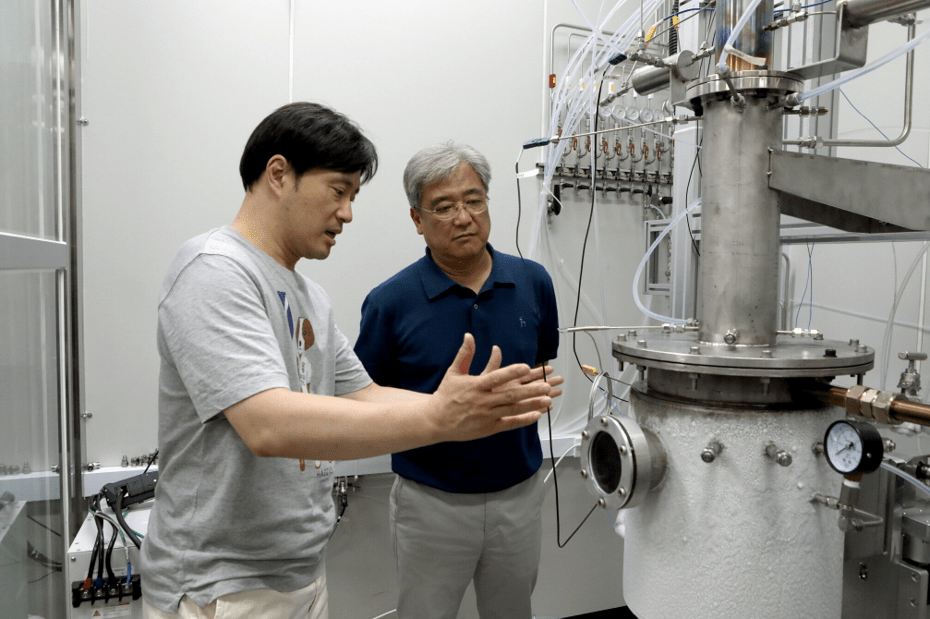

The breakthrough, led by the Korea Institute of Machinery and Materials (KIMM) in collaboration with KRICT, KITECH, KIST, and several universities, marks a potential game-changer in chemical recycling. Unlike conventional methods, it eliminates the need to sort plastics before processing, one of the costliest barriers in today’s recycling systems.

“For the first time worldwide, we have secured a process that can economically convert mixed waste plastics into raw materials,” said Dr. Young-Hoon Song, head of the research program. “Through demonstration and commercialization, this will help solve both waste and carbon issues simultaneously.”

The system relies on plasma, an ultra-energized state of gas to decompose plastics in under 0.01 seconds. Traditional chemical recycling techniques like pyrolysis operate at much lower temperatures (450–600°C) and yield hundreds of by-products, many of little or no use.

By contrast, the hydrogen-fueled plasma torch rapidly dismantles polymer structures while preventing carbon soot formation. This stability allows for continuous operation, converting plastics into high-value compounds such as ethylene and benzene with 70–90% selectivity. After purification, the materials reach over 99% purity, making them suitable for manufacturing new plastics.

The plasma method can even handle waxy residues left behind by other recycling systems, turning them into useful chemicals with over 80% selectivity.

Pilot projects have already demonstrated that producing ethylene via this process is cost-competitive with fossil fuel sources. The research team plans to begin long-term demonstration operations in 2026, paving the way for industrial-scale deployment.

The potential impact could be transformative. If powered by renewable energy, the method offers a carbon-free recycling pathway, tackling both the global plastic waste crisis and climate concerns.

Beyond recycling, the team notes that several sub-technologies developed during the project could be adapted for other sectors. These include greenhouse gas treatment in semiconductor and display manufacturing and the production of high-value materials.

“This research shows the versatility of plasma technologies,” said Dr. Dae Hoon Lee, another lead researcher. “It’s not just about recycling waste; it could reshape how industries handle emissions and produce materials.”