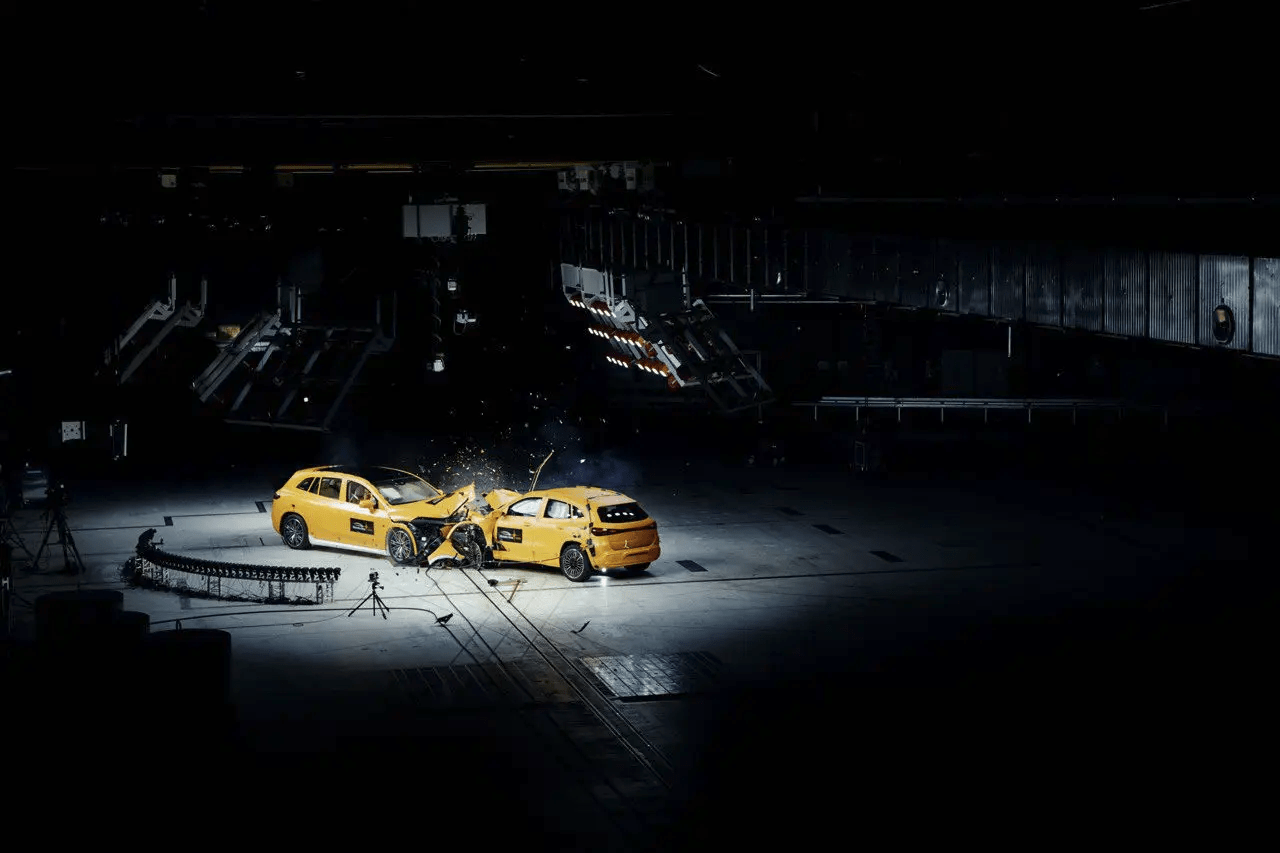

In the relentless pursuit of a cleaner and sustainable future, the automotive world is embracing electric vehicles (EVs). However, to pave the way for mass adoption of this transformative technology, misconceptions regarding EV safety and reliability need to be debunked. Mercedes-Benz, a stalwart in the industry, has taken a bold step to address these concerns head-on by becoming the world’s first car manufacturer to publicly conduct a frontal offset crash test between two EVs.

Contrary to conventional New Car Assessment Program (NCAP) crash tests that employ artificial setups, Mercedes-Benz’s groundbreaking experiment simulated a real-life collision scenario. In this daring feat, an EQA and an EQS SUV, both electric vehicles, collided head-on with a 50 percent overlap, hurtling towards each other at a speed of 34.7 mph (56 km/h).

Mercedes-Benz’s resounding success in this test dispels the notion that EV safety is contingent solely on the driving system. In standard crash tests, vehicles undergo frontal collisions with a 1,400 kg trolley featuring an aluminum honeycomb barrier, simulating the front of another car. The speed of impact is usually set at 31 mph (50 km/h) with an overlap. However, Mercedes-Benz went above and beyond by employing real EVs, weighing around 2.2 and three tonnes, respectively, and driving them at a higher speed of 34.7 mph. This resulted in a cumulative crash energy far exceeding legal limits.

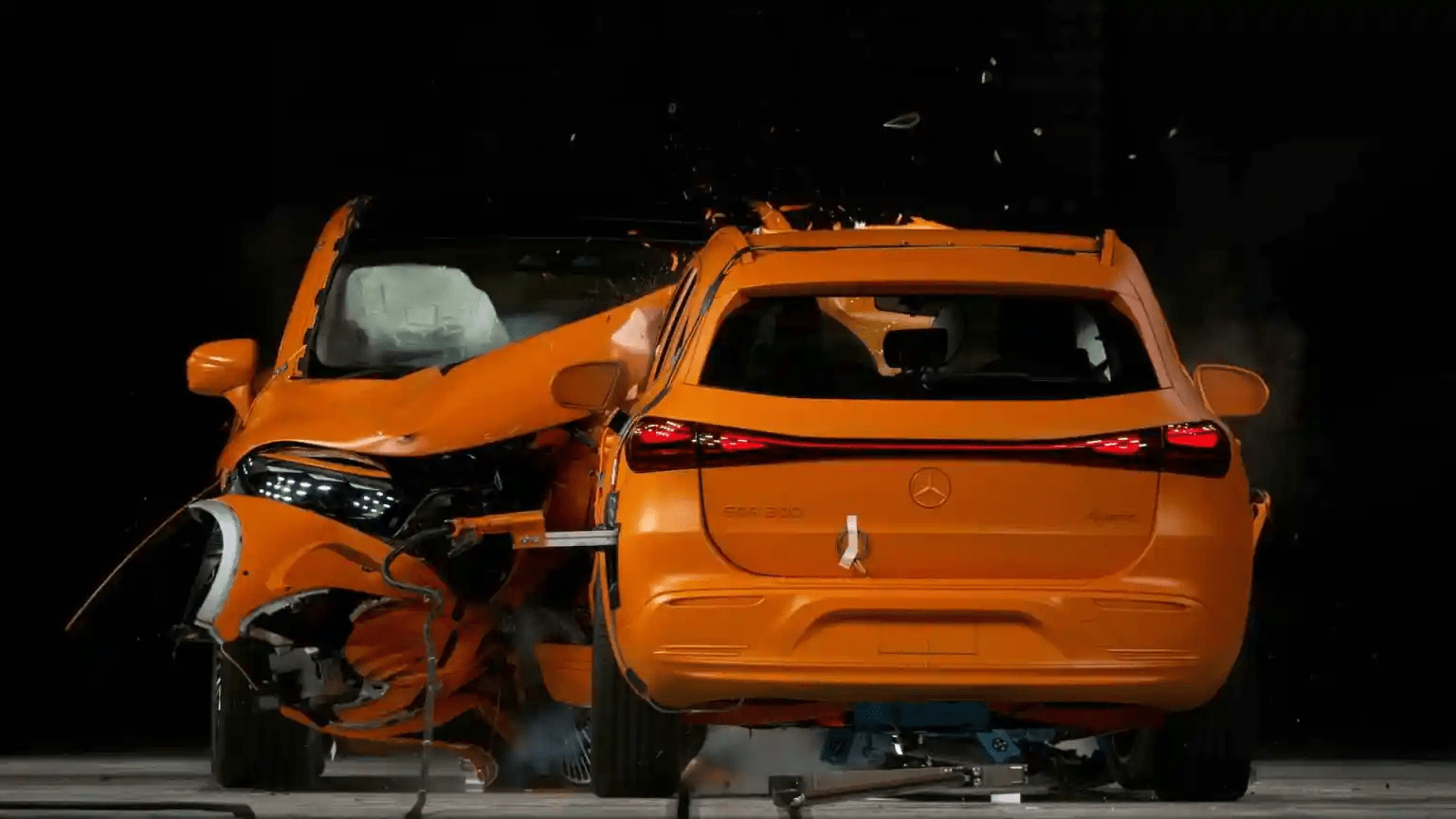

The results were astonishing. The vehicles effectively absorbed the collision energy through deformation, leaving the passenger safety cells intact and the doors operable. In an emergency, this design would facilitate the occupants’ ability to exit the vehicle on their own or enable first responders to reach them. Crucially, the high-voltage system in both the EQA and EQS SUVs automatically shut off during the collision.

Mercedes-Benz noted that this test scenario emulates a common accident type on rural roads, such as during a failed overtaking maneuver. They selected the test speed considering that real drivers would typically attempt to brake before the worst-case collision. Based on the analysis of numerous measurement points per dummy, the crash test’s comprehensive results indicate a minimal chance of severe to fatal harm.

The experiment reaffirms that the established crumple zones and modern restraint systems in these electric cars offer robust protection for occupants, akin to traditional internal combustion engine (ICE) vehicles. All safety equipment, including airbags and belt tensioners with force limiters, functioned as expected. This real-world crash test corroborated the findings derived from multiple computer simulations, underlining Mercedes-Benz’s commitment to safety.

Furthermore, addressing another concern regarding EVs, Mercedes-Benz has developed a multi-stage high-voltage protection strategy to safeguard its electric cars against fire and explosions. This system comprises eight critical components, ensuring the safety of the battery and its components with voltages exceeding 60 volts. Notably, it features separate positive and negative wiring and a self-monitoring high-voltage system that promptly shuts down in the event of a catastrophic accident, as demonstrated during the test.

In a visionary pledge that aligns with the World Health Organization’s “Vision Zero” initiative, Mercedes-Benz aspires to achieve “zero accidents involving a Mercedes-Benz vehicle” by 2050. This ambitious commitment, voiced by Markus Schäfer, Member of the Board of Management of Mercedes-Benz Group AG and Chief Technology Officer, mirrors the industry’s profound dedication to redefining safety and sustainability in the realm of electric vehicles.

In essence, Mercedes-Benz’s pioneering frontal offset crash test underscores that EVs are not just the future; they are the future, fortified with innovation and safety measures that are second to none.