Gears are used for transferring motion and torque between mechanical components in devices. The design and construction of the gear may determine the direction of movement and increase the output speed or torque. Gears are toothed, mechanical transmission elements that are used to transfer power and some of the types of gears are spur gears, Helical gears, bevel gears, worm gears, and rack gears. Operating in mated pairs, they mesh their teeth with the teeth of another gear which prevents slipping during the transmission process. Each toothed component is attached to a base component. If the gears are not of the same sizes, the system experiences an advantage that allows a change in speed and torque.

As far as the mechanical process of gears is concerned, it can be made to work on the basis of eddy currents. Such a contribution has been made by scientists. And thus, gears are made that do not have any mechanical contact at all. Their teeth seem invisible.

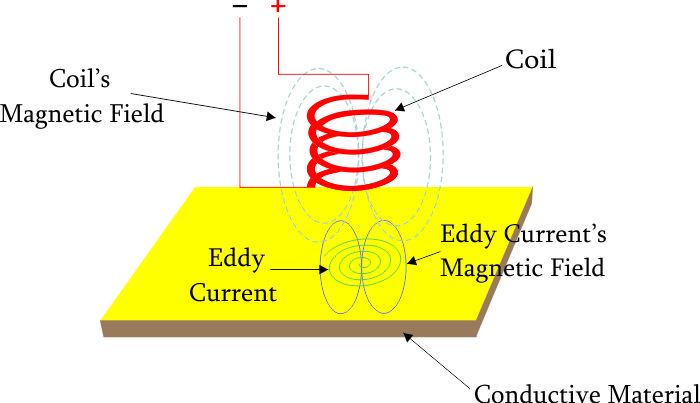

A round metal plate, a conductive flywheel, a handful of neodymium agents, and a motor to spin the metal plate are required to operate it through eddy currents. As eddy currents circulate in conductors. They are an outcome of electromagnetic induction and are induced by the changing magnetic fields and flow in closed loops perpendicular to the plane of the magnetic field. These currents also produce their own magnetic field while flowing through the conductor.

So, through the usage of the above-mentioned apparatus, invisible gears are made to work. The magnetic field induces eddy currents in a non-magnetic material, an aluminum flywheel. These electric currents move around in loops and as they produce their own magnetic field that opposes the action of magnets placed underneath, the aluminum flywheel starts to spin. And it seems just like a magical trick.