Building structures are a significant contributor to carbon emissions, with the production of cement alone responsible for 8% of global emissions. Josh Dorfman, a serial entrepreneur watched as the price of wood skyrocketed. It got harder to find high-quality lumber, and he started wondering what alternative materials might be possible to use.

He connected with two former SpaceX engineers who were interested in wood alternatives for another reason: They saw an opportunity to rework construction materials to speed up carbon capture at a large scale.

Trees suck up CO2 as they grow, but fast-growing grasses, they realized, can capture even more—and can be made into structural panels that are used to build homes.

“We can skip the tree altogether,” says Huade Tan, who previously helped develop spacecraft at SpaceX. Dorfman, Tan, and fellow SpaceX engineer Nathan Silvernail cofounded Plantd, a North Carolina-based building materials startup, to bring new products to market.

Plantd is a startup that makes engineered building materials out of grass. Based in Durham, North Carolina, Plantd closed its Series A funding round to the tune of $10 million in January. Two of its three cofounders are former SpaceX engineers.

The company, which just raised $10 million in a Series A funding round, after testing several different types of grass and other raw materials, settled on a perennial long grass that can grow 20 to 30 feet in a year, absorbing as much as 30 tons of carbon. “Our vision is to take carbon out of the atmosphere as fast as possible and lock it away,” Dorfman says.

Managed plantations typically harvest pine trees after 15 years, whereas grass can be harvested up to three times per season and continues to grow. This makes it a more readily available resource and can help prevent supply chain shortages.

Plantd is also partnering with a local farmer near Durham to start growing several acres of its grass this year. Dorfman expects that scaling up and finding more farmers won’t be difficult, because many farmers in North Carolina who have historically grown tobacco are looking to replace it with a more sustainable, better-paying crop.

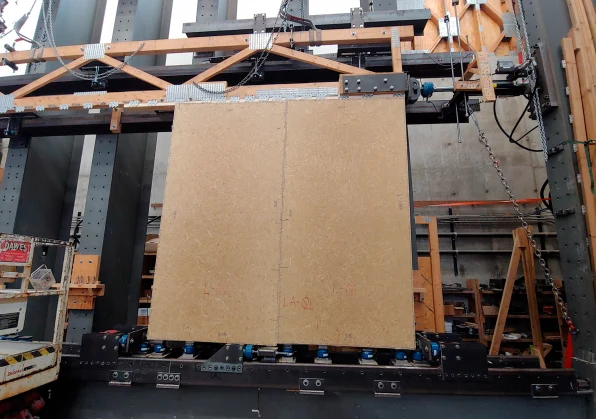

The team is creating their own automated, modular, all-electric machinery to shred the fiber from the grass and reconstruct it into structural panels for use in construction, such as walls, roofs, and subfloors.

The cellulose fiber in the grass is comparable to the strong fibers in wood and can be manipulated in a similar manner to engineered wood.

“Our value proposition is about affordability, durability, and sustainability,” Dorfman said. “We believe the future is going to be abundant. With Plantd, the way to solve climate change is to build more, not less, because every new home and building is an opportunity to lock away atmospheric carbon.”

However, the startup is developing custom equipment to improve the final product’s quality, maintain cost-efficiency, and reduce the production’s carbon footprint.