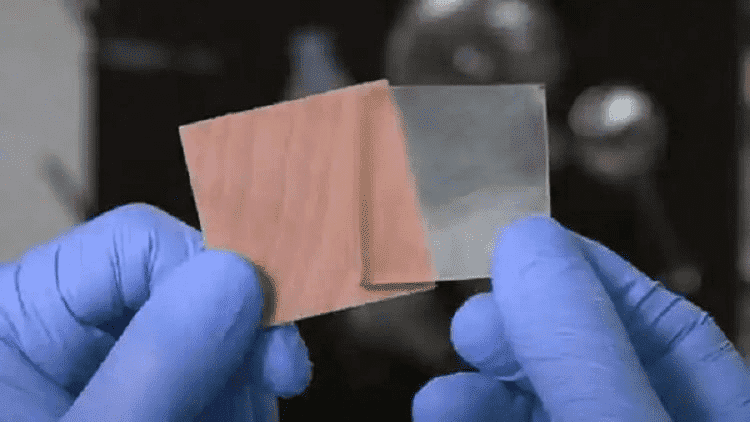

Researchers at the University of Texas at Austin are actively working on making a plastic that would emulate real life. It would be like many life forms that are soft and stretchy in some places and hard and rigid in others.

They used only light and a catalyst to change the properties such as hardness and elasticity in molecules of the same type. The resulting material is ten times stronger than natural rubber and could very well change the flexibility of electronics and robotics.

The findings were published last year in the journal Science.

“This is the first material of its type,” said Zachariah Page, assistant professor of chemistry and corresponding author on the paper. “The ability to control crystallization, and therefore the physical properties of the material, with the application of light is potentially transformative for wearable electronics or actuators in soft robotics.”

“Oftentimes, when bringing materials together, particularly if they have very different mechanical properties, they want to come apart,” Page said.

Page and the team at the University of Texas at Austin were successful in controlling and changing the structure of a plastic-like material.

After several trials, a catalyst was found that when added to the monomer and then shown visible light, gave a semicrystalline polymer that resembles synthetic rubber. A more rigid material was formed in the areas touched by light. The rest of the areas stayed soft and stretchy.

The reaction happens at room temperature. Each raw material is commercially available and economical. Additionally, the reaction takes place in less than an hour, minimizing the use of dangerous waste, which makes the process rapid, inexpensive, energy-efficient, and environmentally benign.

The team is aiming to create a flexible material that can be used to anchor electronic components in such things as medical devices or other wearable tech. Such materials are also extremely useful in robotics.