Engineers at Monash University, in a world-first study, have shown how cutting-edge 3D printing can now produce ultra-strong commercial-grade titanium alloy. This is a huge leap forward for the aerospace, defense, energy, space, and biomedical industries.

Researchers from Australia, led by Professor Aijun Huang, and Dr. Yuman Zhu both of Monash University, manipulated a novel microstructure, through a 3D-printing method.

“Titanium alloys require complex casting and thermochemical processing to achieve the high strengths required for some critical applications,” said Dr. Huang in a statement. “We have discovered that additive manufacturing can exploit its unique manufacturing process to create ultra-strong and thermally stable parts in commercial titanium alloys, which can be directly implemented in service.”

Professor Huang expanded on this statement. “After a simple post-heat treatment on a commercial titanium alloy, adequate elongation, and tensile strengths over 1,600 MPa is achieved, the highest specific strength among all 3D printed metal to date. This work paves the way to fabricate structural materials with unique microstructures and excellent properties for broad applications.”

The main properties of the titanium alloy are attributed to the unusual formation of dense, stable, and internally twinned nanoprecipitates, which are rarely seen in traditionally processed titanium alloys. The technique used here is Additive Manufacturing (AM).

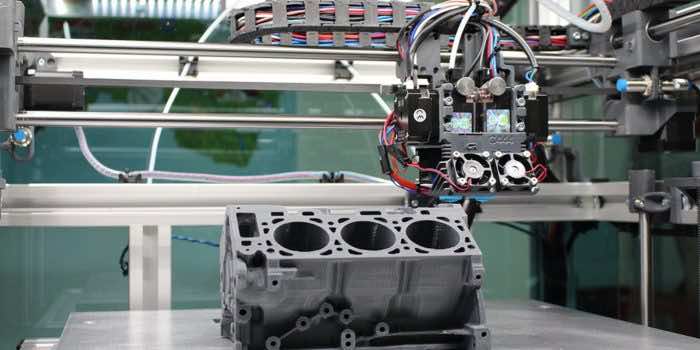

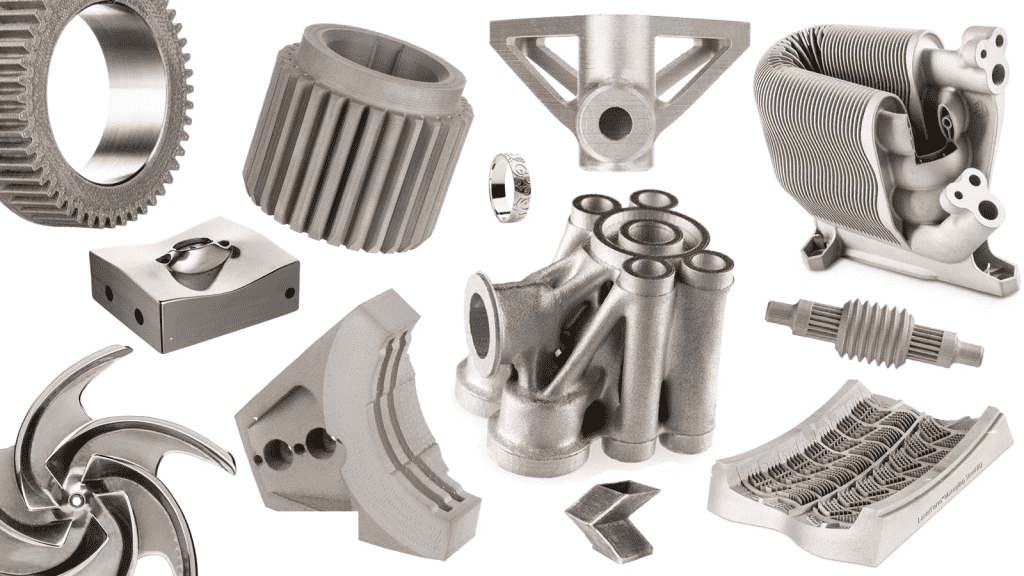

AM is an enabling technology that gives unprecedented design freedom. In this type of 3D creation of titanium alloys. Titanium, in general, is much stronger than aluminum alloys, and lighter than steel, with makes them more energy efficient.

The buy-to-fly ratio, the ratio of starting to final weight, is closer to 1:1 rather than the 10:1 to 40:1 that can be realized when using conventional manufacturing techniques. The use of, and the number of AM titanium products currently used in industry is still limited when compared to conventionally produced titanium components.

The work done at Monash has produced a more fundamental understanding of the densities, segregation of elements, and unique solidification structures.

The applications can begin immediately, which is rare for a study or research project.

The full study was published in Nature Materials.