A revolutionary eco-friendly building material named Sugarcrete, derived from the fibrous waste of sugarcane crops known as bagasse, has garnered international acclaim by winning a Climate Positive Award. Developed through collaboration between the University of East London and Tate & Lyle Sugars, Sugarcrete presents a sustainable alternative to traditional construction materials.

Sugarcrete combines sugarcane bagasse with proprietary mineral-based binders. The resulting mixture is compressed and cured, yielding high-strength blocks suitable for construction, surpassing industry standards in fire resistance, compressive strength, thermal conductivity, and durability.

The advantages of sugarcane over conventional materials are compelling. Notably, it boasts a faster curing time of one week compared to the four weeks required for concrete. Moreover, its weight is only a fraction of traditional blocks, ranging from one-quarter to one-fifth, making it a more efficient and cost-effective alternative.

A key factor contributing to Sugarcrete’s sustainability lies in its economic feasibility, particularly in regions where sugarcane is abundant. Instead of discarding bagasse as waste, local farmers can sell it to companies for Sugarcane production. This closed-loop system reduces waste and offers an affordable option for construction projects that might have been financially prohibitive with imported concrete.

The environmental benefits extend to Sugarcrete’s significantly lower carbon footprint, reportedly 15% to 20% that of concrete. Traditional cement production, a concrete component, is a notable contributor to CO2 emissions. Sugarcrete’s innovative approach addresses this issue by utilizing bagasse waste, thus minimizing its impact on climate change.

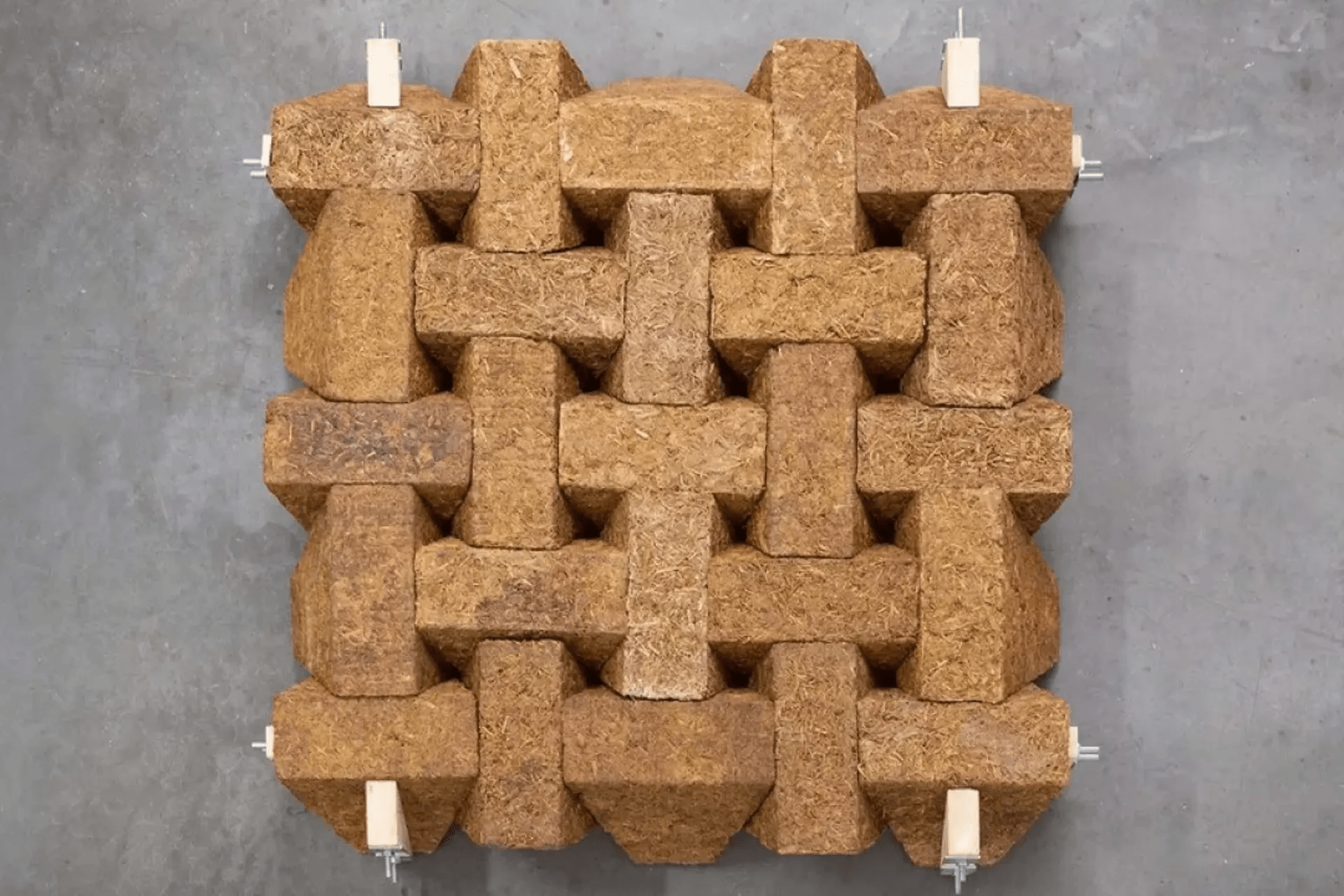

Sugarcrete has already showcased its potential in prototype modular floor slabs, employing interlocking blocks with minimal steel reinforcement. Compared to concrete slabs, Sugarcrete requires up to 90% less steel, enhancing its structural efficiency and reducing environmental impact. The technology earned recognition at the United Nations Climate Change Conference, where it received the circular economy section of the Climate Positive Awards from Green Cross UK.

As Sugarcrete advances toward commercialization, the team is actively seeking agricultural partners in Global South nations, marking a crucial step in bringing this sustainable construction solution to a global audience. The success of Sugarcrete exemplifies the transformative power of circular economy initiatives that prioritize waste reduction and material reuse in the pursuit of climate-positive solutions.