Researchers from RMIT University in Australia have developed a groundbreaking new technique for producing hydrogen from seawater. The method, which is both cheaper and more energy efficient than current methods, is a significant step towards the creation of a truly sustainable green hydrogen industry.

Hydrogen is widely regarded as a key component in the transition towards a low-carbon economy, as it can be used as a clean and renewable energy source. However, the production of hydrogen is currently a costly and energy-intensive process, which has prevented its widespread adoption as a replacement for fossil fuels.

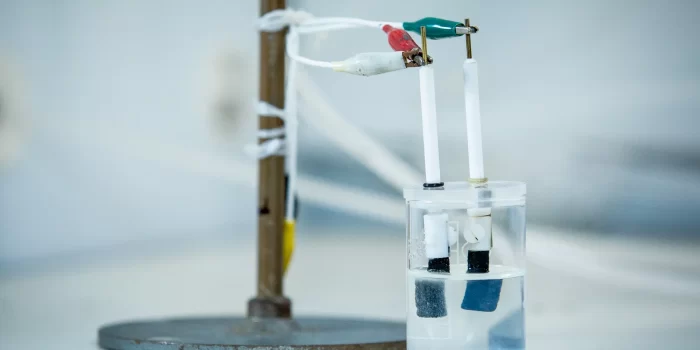

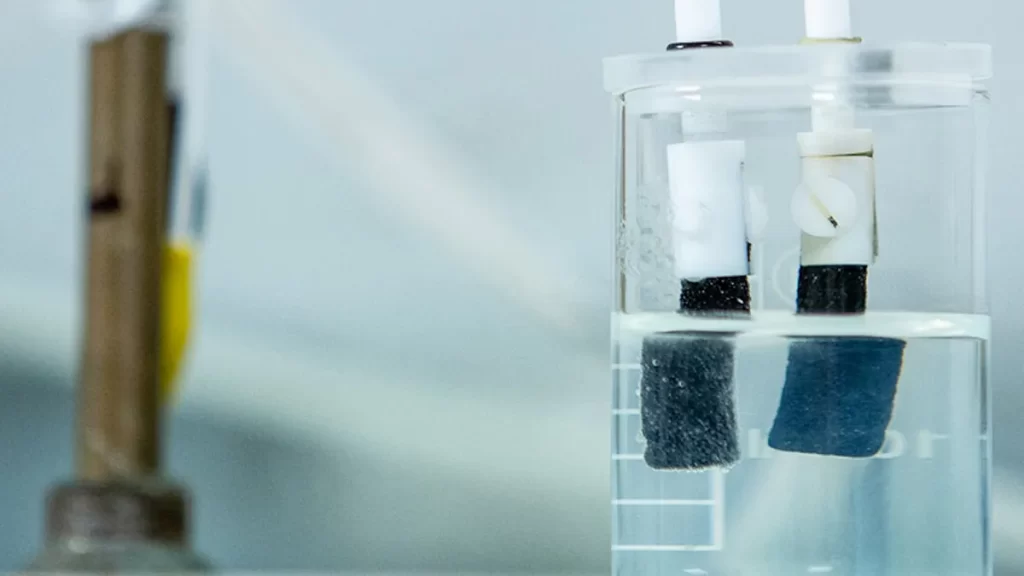

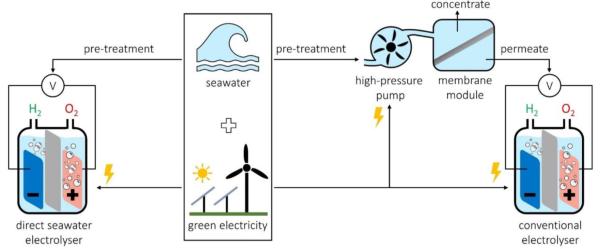

To make green hydrogen, an electrolyzer is used to send an electric current through water to split it into its component elements of hydrogen and oxygen. These electrolyzers currently use expensive catalysts and consume a lot of energy and water; it can take about nine liters to make one kilogram of hydrogen. They also have a toxic output—not carbon dioxide but chlorine. And this process is very expensive.

The new approach devised by a team in the multidisciplinary Materials for Clean Energy and Environment (MC2E) research group at RMIT uses a special type of catalyst developed to work specifically with seawater.

The study, with Ph.D. candidate Suraj Loomba, focused on producing highly efficient, stable catalysts that can be manufactured cost-effectively. “These new catalysts take very little energy to run and could be used at room temperature,” Mahmood Vice-Chancellor’s Senior Research Fellow at RMIT said. “While other experimental catalysts have been developed for seawater splitting, they are complex and hard to scale.” “Our approach focused on changing the internal chemistry of the catalysts using a simple method, which makes them relatively easy to produce at large scales, allowing them to be readily synthesized at industrial scales,” Loomba explained.

According to Mahmood, the technology has the potential to significantly reduce the cost of electrolyzers – enough to meet the Australian Government’s goal of $2 per kilogram of green hydrogen production and make it competitive with fossil fuel-sourced hydrogen.

The potential applications of this technology are vast, from powering homes and businesses to providing a source of clean fuel for vehicles. Additionally, the abundance of seawater as a resource means that the scalability of this technique is virtually limitless.

Overall, the breakthrough made by the RMIT researchers is a major step forward in the creation of a sustainable hydrogen industry. By providing a cheaper and more efficient method for producing hydrogen, this technology has the potential to revolutionize the way we think about energy production and consumption and to help us build a greener, more sustainable future.