Researchers from the U.S. Department of Energy’s (DOE) Princeton Plasma Physics Laboratory (PPPL) have announced that they can build powerful magnets much smaller than ever before, a press statement reveals. This would be a huge leap for nuclear fusion.

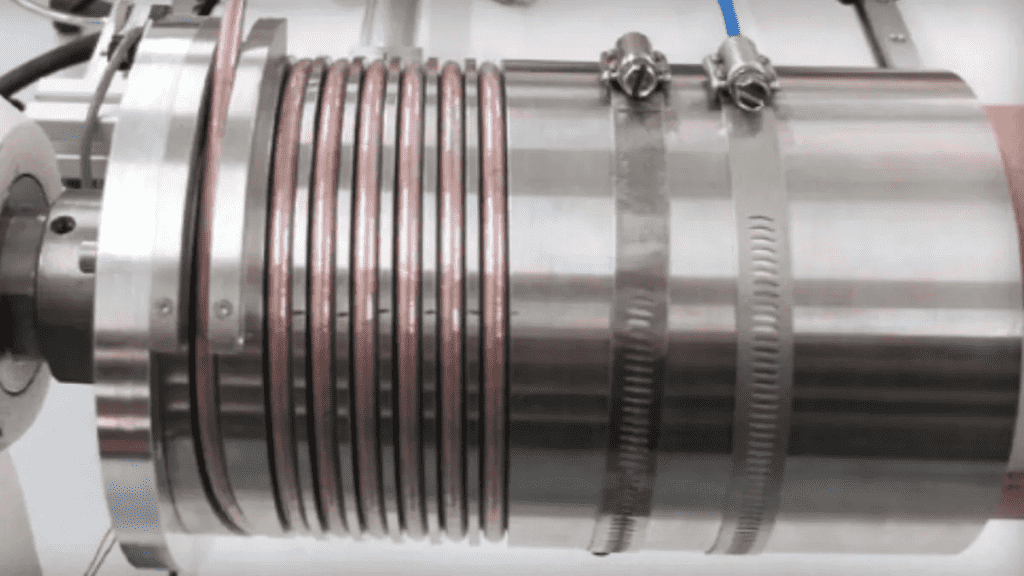

The scientists found a new method for building high-temperature superconducting magnets that are made of material that conducts electricity with practically no resistance at temperatures warmer than before. The smaller magnets will more easily fit inside spherical tokamaks, which are being investigated as a potential alternative to the more conventional doughnut-shaped tokamaks.

“To do this, you need a magnet with a stronger magnetic field and a smaller size than current magnets,” explained Yuhu Zhai, a principal engineer at PPPL and lead author of a paper on the new magnets published in IEEE Transactions on Applied Superconductivity. “The only way you do that is with superconducting wires, and that’s what we’ve done.”

The magnets could also potentially enable scientists to develop smaller tokamaks, which could improve performance as well as reduce the cost of construction and operation. “Tokamaks are sensitive to the conditions in their central regions, including the size of the central magnet, or solenoid, the shielding, and the vacuum vessel,” said Jon Menard, PPPL’s deputy director for research. “A lot depends on the center. So, if you can shrink things in the middle, you can shrink the whole machine and reduce cost while, in theory, improving performance.”

The concept was applied based on the work of Zhai and colleagues at Advanced Conductor Technologies, the University of Colorado, Boulder, and the National High Magnetic Field Laboratory, in Tallahassee, Florida.

“By removing epoxy from the equation, the researchers also lower the cost of magnet production, which will also result in cheaper tokamaks. The costs to wind the coils are much lower because we don’t have to go through the expensive and error-prone epoxy vacuum-impregnation process,” Zhai said. “Instead, you’re directly winding the conductor into the coil form.”

The first fully operational fusion reactor might be far from us at the moment but this new development is definitely promising.