Scientists at Tsinghua University in China have achieved a significant breakthrough in the field of smart materials. They have developed a special liquid metal coating that can turn regular paper into self-adhesive gadgets capable of conducting heat and electricity. This liquid metal coating has not been explored as a coating before, even though it is commonly used in circuits and wearable sensors.

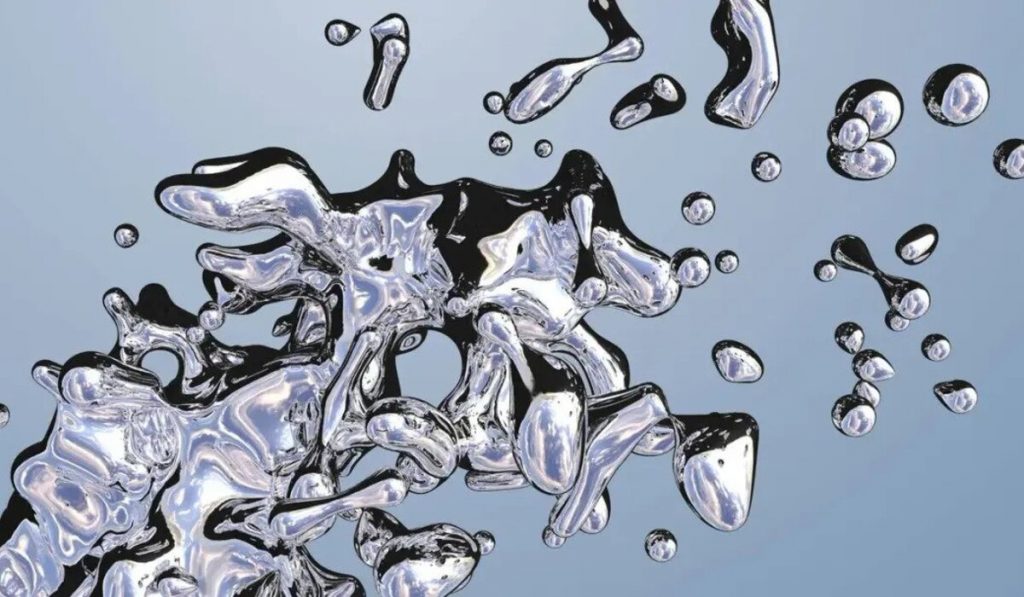

The researchers successfully created a liquid alloy and applied it to paper using a stamping technique, eliminating the need for adhesives. This opens up exciting possibilities for creating lightweight, flexible smart objects and soft robots that can function independently in different environments. The findings of this study, published in the journal Cell Reports Physical Science, highlight the potential of liquid metal as a coating and its various applications.

The team, led by Bo Yuan from Tsinghua University, conducted experiments with different alloy combinations to test the adhesion of the liquid metal coating. They compared an indium/gallium alloy (eGaIn) with an alloy of bismuth, indium, and tin oxide (BiInSn) and found that the latter offered superior adhesion and stability.

Unlike eGaIn, the BiInSn alloy does not undergo oxidation when exposed to air. This ensures reliable adhesion without relying on an oxide film. Furthermore, BiInSn remains solid at room temperature and has a higher melting point, which means it does not turn liquid at temperatures below 144° Fahrenheit (62° degrees).

“We needed to ensure the adhesion of liquid metal to be uniform in large scale on different paper, and to maintain the stability of the coating,” Bo Yuan told Ars Technica. “To solve these problems, we changed pressure applied on the stamp as well as the rubbing speed used in the experiments and finally found the most suitable parameters.”

The team successfully folded paper coated with liquid metal into origami cubes and observed that they could unfold and refold on their own, thanks to the self-adhesive nature of the coating. Moreover, they created 3D structures using individual pieces of metal-coated paper, and these structures maintained their shape without the need for additional binding agents.

The metal coating can be easily peeled off, allowing for recycling and repeated use without damaging the underlying paper.

Bo Yuan and his team aim to develop a coating that maintains its adhesion once solidified. They believe that a bio-friendly paint spray based on this technology could revolutionize packaging, enabling boxes that can open and close by themselves. In the field of healthcare, the coating could be used in bandages that can be easily removed without leaving any residue on the skin.

Soft robots equipped with this liquid metal coating could navigate challenging terrains more easily. The self-adhesive property would allow them to fold or unfold as needed, enabling them to venture into areas that larger rovers cannot access.

This study represents a significant advancement in smart material research. “Utilizing our method, one can quickly create smart materials with good thermal and electrical conductivity as well as stiffness-tunable ability,” Yuan added. “I think that this method may provide a new route for designing space explorers.”