Pratt & Whitney Canada and Gulfstream Aerospace Corporation achieved a significant milestone in sustainable aviation by completing a transatlantic flight using 100 percent sustainable aviation fuel (SAF). The accomplishment involved a Gulfstream G600 business jet equipped with Pratt & Whitney PW800 series engines customized to run on SAF. The purpose of the flight was to showcase the functionality of the engine and aircraft in a fully operational setting, supporting future specifications for 100 percent SAF use.

The transatlantic flight took place on November 19, with the Gulfstream G600 departing from Savannah, Georgia, and landing in Farnborough, United Kingdom. Both engines ran on hydro-processed Esters and Fatty Acids (neat HEFA), a type of jet fuel with at least 70 percent less CO2 emissions over its lifecycle compared to traditional fossil fuel. The SAF used for the flight was produced by World Energy and supplied by World Fuel Services.

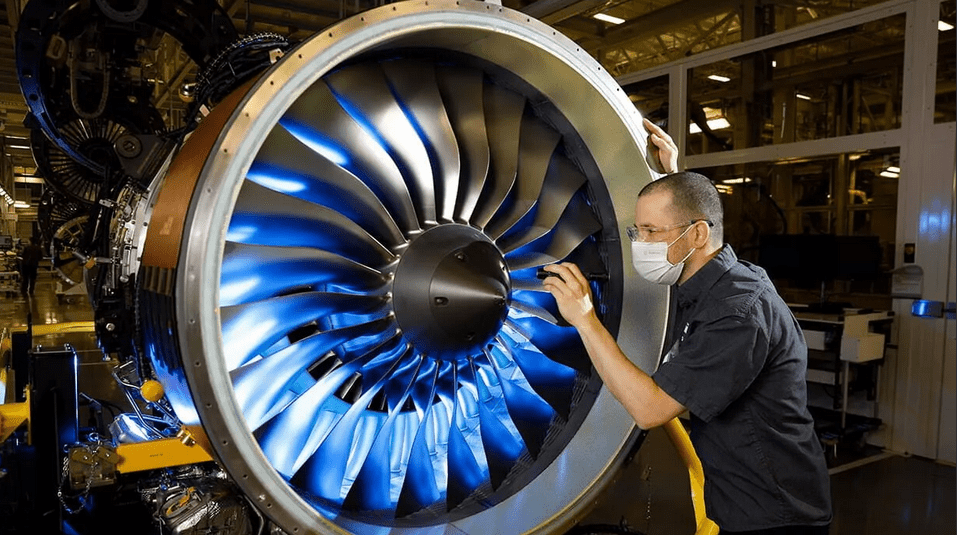

The collaboration between Gulfstream and Pratt & Whitney Canada, spanning over a decade, resulted in the G600 jet, featuring the PW815GA engines. The PW800 engine family, a cornerstone in the business jet category, has accumulated over 330,000 flying hours. Transitioning to 100 percent SAF fuel with such engines would significantly contribute to sustainable aviation.

Sustainable aviation fuels, derived from non-fossil-based feedstocks like plant oils, cooking oil, and municipal waste, offer a pathway to lower the carbon impact of aircraft operations. SAFs can potentially reduce carbon emissions by 80 percent throughout their lifecycle compared to traditional jet fuel. They serve as a “drop-in” solution, requiring no new infrastructure or modifications to existing aircraft, making them a practical option for the aviation industry’s carbon footprint reduction.

While SAFs present a promising solution, the challenge lies in scaling up production to meet the increasing demand driven by net-zero goals. Pratt & Whitney emphasizes the need for collaboration between governments and businesses to encourage investments in production infrastructure and enhance the profitability of SAF for operators. According to the company, an estimated $1.1–1.4 trillion investment in SAF production infrastructure is required to achieve net-zero targets by 2050.

In 2019, SAFs accounted for only 0.01 percent of jet fuel demand, highlighting the urgency for rapid scaling in the sector. The success of flights using 100 percent SAF marks a positive step toward a more sustainable future for aviation, but addressing production challenges is crucial for widespread adoption.