Nanotechnology researchers at The University of Texas at Dallas have developed a novel material that can be recycled to provide people with energy and power, and it is derived from an unlikely source: yarn.

In a recent study, UT Dallas researchers and collaborators report advancements in high-tech yarns called “twistrons” that create energy when stretched or twisted. It is made the same way as regular wool or cotton yarns.

“Twistrons sewn into textiles can sense and harvest human motion; when deployed in salt water, twistrons can harvest energy from the movement of ocean waves; and twistrons can even charge supercapacitors,” the researchers said.

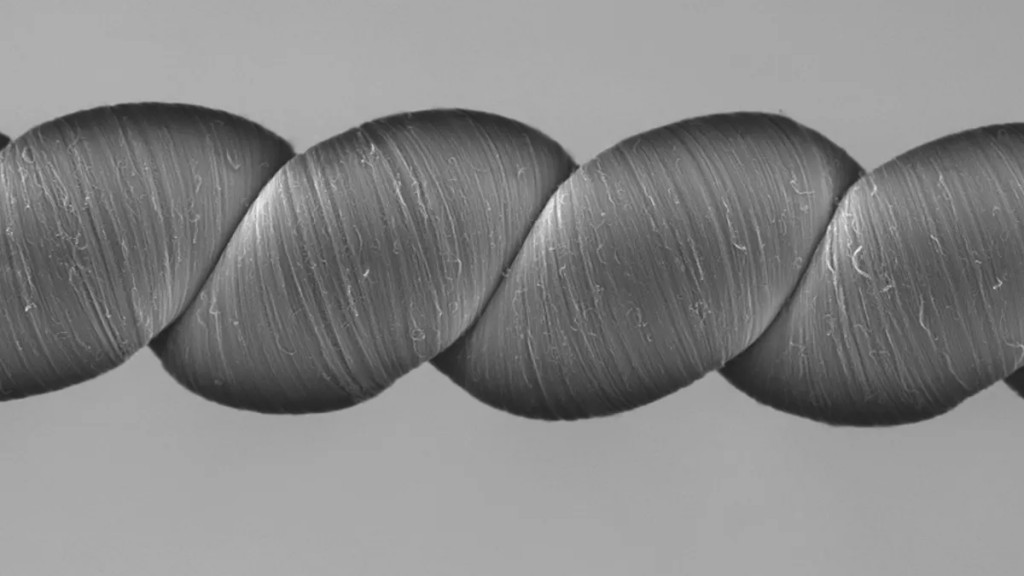

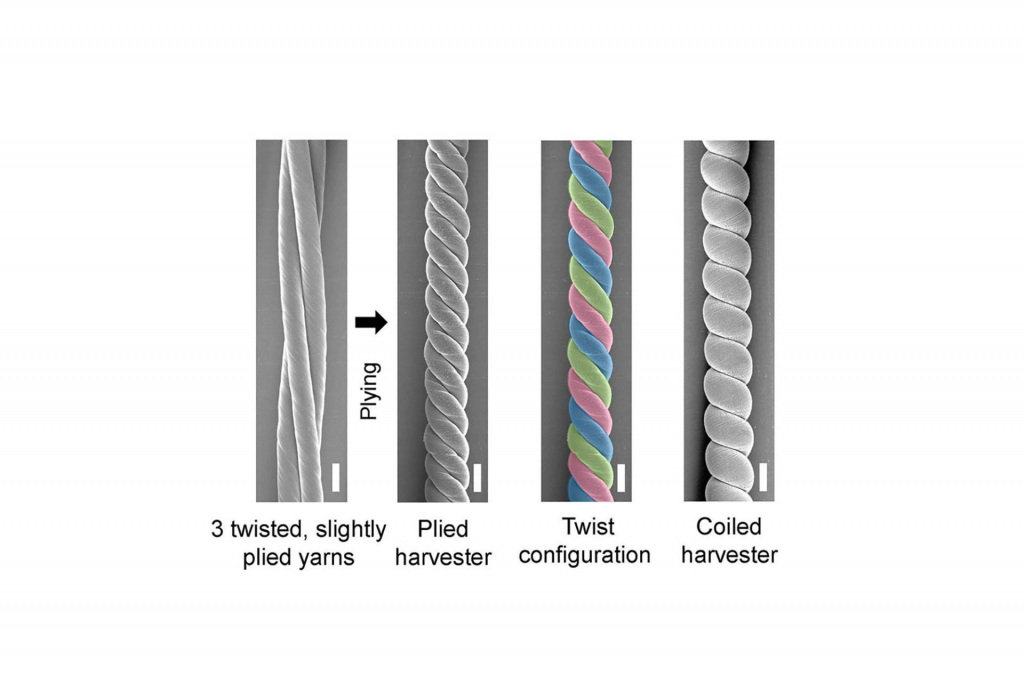

This study relied on earlier findings that were published in 2017. Twisting the strands until they coil like an overtwisted rubber band was how the earlier forms of twistrons were made. Then, continuously stretching and releasing, or twisting and untwisting, the coiled yarns produce electricity.

However, the researchers did not coil the fibres to the point of twisting them in the current study. Instead, three different spun carbon nanotube strands were joined to form a single yarn that resembled conventional textile yarns but with a twist.

“Plied yarns used in textiles are typically made with individual strands twisted in one direction and then plied together in the opposite direction to make the final yarn. This heterochiral construction provides stability against untwisting,” said Dr. Ray Baughman, director of the Alan G. MacDiarmid NanoTech Institute at UT Dallas and the corresponding author of the study.

“In contrast, our highest-performance carbon-nanotube-plied twistrons have the same handedness of twist and plying — they are homochiral rather than heterochiral,” said Baughman, the Robert A. Welch Distinguished Chair in Chemistry in the School of Natural Sciences and Mathematics.

In tests using the plied CNT yarns, the researchers reported an energy conversion efficiency of 17.4% for tensile (stretching) energy harvesting and 22.4% for twisting energy harvesting. Their coiled twistrons’ earlier incarnations had a 7.6% peak energy conversion efficiency for tensile and torsional energy harvesting.

Baughman asserts that the compression of the yarn while stretching or twisting is the reason for the higher performance of the plied twistrons. With this method, the plies come into contact with one another, changing the electrical properties of the yarn.

Additionally, the new yarns can track and gather body movements. In one experiment, the researchers created a patch of cotton fabric from which a person’s elbow was wrapped. The participant bent their elbow repeatedly, generating electrical signals.

The study is published in the journal Nature Energy.