If you are a glasses wearer, you would know how annoying and inconvenient it is when they fog up. A new treatment has been discovered that could make polycarbonate lenses permanently fog-free and self-cleaning, to boot.

The treatment was developed at Singapore’s Nanyang Technological University. The process begins with the lens (or other plastic surfaces) being treated with oxygen plasma. This is done both to clean it, and to improve the adhesion of a thin film which will subsequently be deposited onto it.

That transparent film comprises two layers – one consisting of silicon dioxide, the other of titanium dioxide – and it’s placed on the plastic through a pulsed laser deposition process. The latter involves using a laser to vaporize each of the two-layer materials within a vacuum chamber. As the vaporized silicon dioxide and titanium dioxide rise upwards, they’re finely deposited on the plastic substrate, which is located at the top of the chamber.

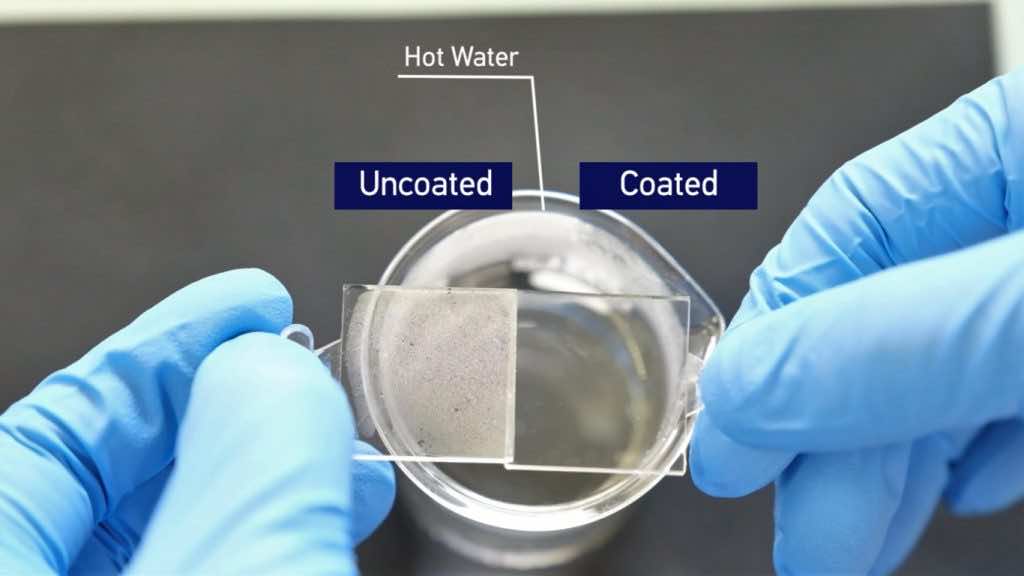

This mechanism works by causing tiny water droplets – which settle on the lens – to spread out into a uniform film that is easily seen through. It does this within just 93 milliseconds of a droplet touching the film.

Tests also revealed that the film resisted abrasion when rubbed with a cheesecloth pad (a standard abrasion-resistance testing technique). Also, it remained bonded to the plastic when adhesive cellophane tape was applied to it and then peeled away. And as a bonus, when the treated plastic is exposed to sunlight (or another ultraviolet light source), the titanium dioxide is triggered to break down organic contaminants such as dirt particles and bacteria.

“The reported results prove the multi-functionality of our coating,” said Ph.D. Student Sun Ye, first author of the study. “It is antireflective, anti-fogging, and self-cleaning. Additionally, the fabrication approach is fast and easy to implement with great durability. This makes our innovation unique among other anti-fogging methods which tend to end up with coatings with limited functions.”

Source: Nanyang Technological University