Fraunhofer scientists have developed a groundbreaking method to significantly cool electronic components using ultra-thin diamond membranes, leveraging diamond’s exceptional thermal conductivity.

Heat generation is a common issue in electronics, often leading to component damage and posing safety risks. Traditional heat management techniques involve using copper or aluminum heat sinks, necessitating additional insulating layers due to their electrical conductivity. To address this, the Fraunhofer team turned to diamond, known for its outstanding thermal conductivity while being an electrical insulator.

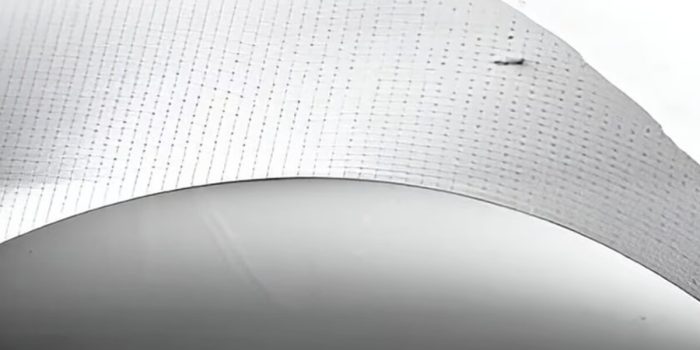

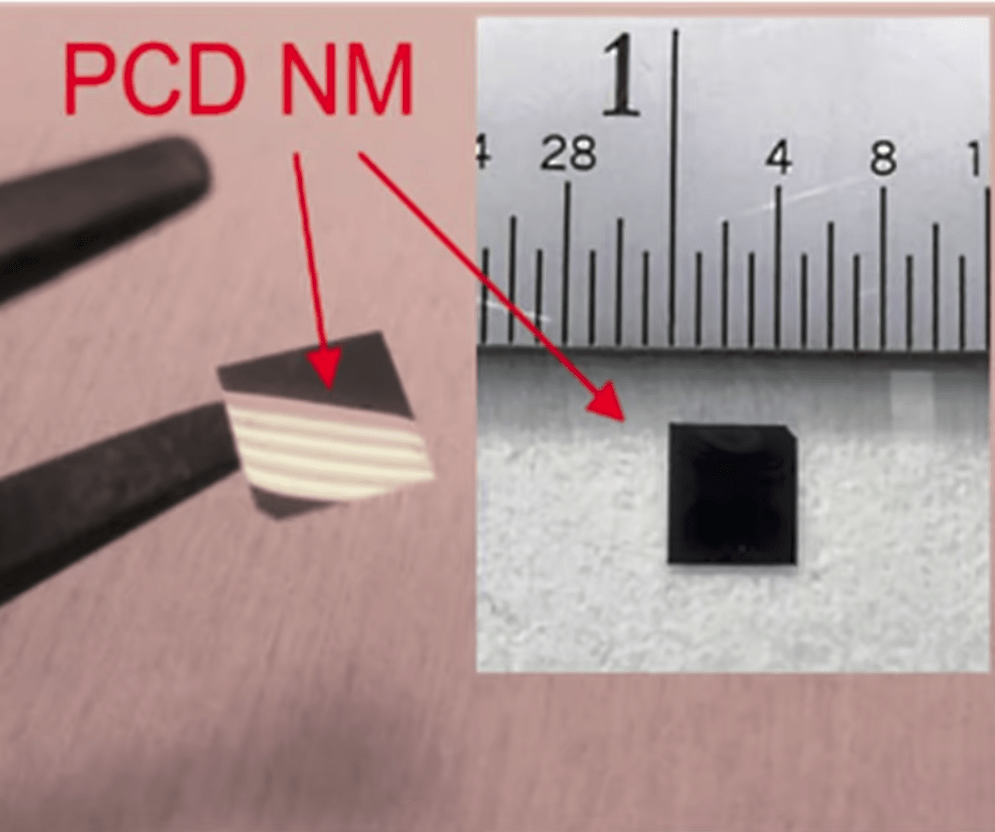

The researchers aimed to replace conventional insulating layers with their diamond nanomembranes, which efficiently transfer heat to copper due to diamond’s conductive properties. These nanomembranes, merely a micrometer thick and flexible, can be easily integrated into electronic components or cooling circuits by gentle heating.

Produced by growing polycrystalline diamond on silicon wafers and subsequently detaching and etching the diamond layers, these membranes offer a promising solution for heat management in electronics.

“We want to replace this intermediate layer with our diamond nanomembrane, which is extremely effective at transferring heat to the copper, as diamond can be processed into conductive paths,” said Matthias Mühle, a scientist on the project. “As our membrane is flexible and free-standing, it can be positioned anywhere on the component or the copper or integrated directly into the cooling circuit.”

The team predicts that the diamond nanomembranes could reduce electronic component heat loads by a factor of 10, enhancing energy efficiency and device lifespan. Moreover, incorporating these membranes into electric vehicle charging systems could potentially increase charging speeds by five times.

A notable advantage is the scalability of the manufacturing process, as diamond nanomembranes can be produced on silicon wafers, facilitating industrial-scale production.

The researchers have filed a patent for the technology and plan to commence testing later this year, focusing on applications in inverters and transformers for electric vehicles and telecommunications. This innovation holds promise for revolutionizing heat management in electronics, offering a path towards more efficient and durable devices.