The University of Maine has introduced the world’s largest polymer 3D printer, known as the Factory of the Future 1.0 (FoF 1.0) in partnership with the US government in response to the increasing demand for more affordable housing choices. With a large amount of greenhouse gas emissions coming from the construction sector, the FoF 1.0 seeks to print dwellings with a reduced carbon footprint.

The FoF 1.0 is a significant improvement over its predecessor, printing at four times the pace. Dr. Habib Dagher, the head of the Advanced Structures and Composites Centre, emphasises the need of building high-quality homes that people want to live in rather than focusing just on pricing.

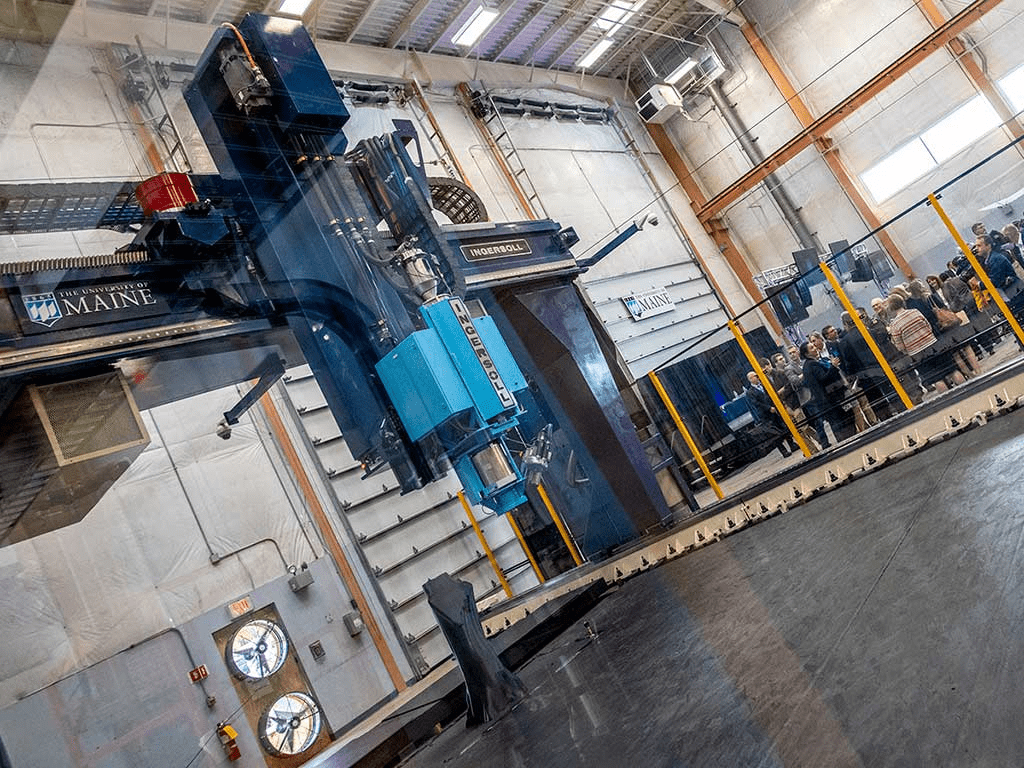

The FoF 1.0 was formally introduced with stakeholders and officials from several government departments. Its uses are not limited to housing. Because of its enormous dimensions, it can print items up to 96 feet long, 32 feet wide, and 18 feet high at a rate of 500 pounds of material per hour. The FoF 1.0’s adaptability makes it an indispensable tool for a variety of sectors, including national security and manufacturing.

Sen. Susan Collins highlights the potential of the FoF 1.0 to assist the Department of Defence in advanced manufacturing while praising the University of Maine’s inventiveness and labour capabilities. The printer’s versatility in handling robotic arm operations and switching between additive and subtractive manufacturing functions highlights its importance across a range of sectors.

By using recyclable components, the FoF 1.0 also adheres to sustainable manufacturing methods. In order to promote a circular economy, Dr. Dagher highlights the printer’s recyclability, which enables the disassembly and reprinting of 3D-printed parts.

The FoF 1.0 serves as the centerpiece of the upcoming Green-Engineering and Material Factory of the Future (GEM), a manufacturing innovation center. This initiative reflects the University of Maine’s commitment to nurturing future leaders in engineering and computing through sustainable models of manufacturing.