Like other smartphone manufacturers, Apple has been urged by the European Union to develop a universal charging cable. However, if it refuses to give you an iPhone with a USB-C connector, you could just build one yourself.

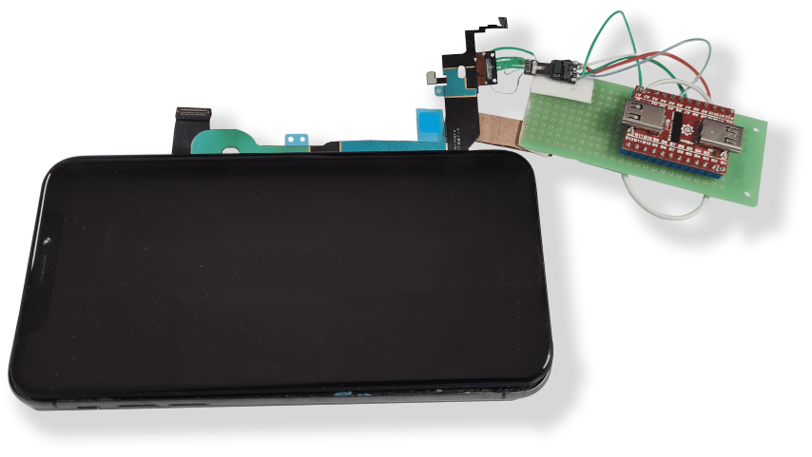

That’s what Ken Pillonel, an engineering student at the Swiss Federal Institute of Technology, EPFL, did. Pillonel designed a unique PCB ribbon cable that fits inside an iPhone X and can charge and transport data over USB-C. The process, according to Apple Insider, takes months to complete.

Apple has already begun to transition several of its products to USB-C connectors. However, the popular iPhone will continue to use the Lightning connector even in its most recent iteration. It is still unclear if the company will fight the EU order or comply with it; nevertheless, Pillonel has created a video demonstrating how it can be done.

This is merely a preview of the actual video:

However, Pillonel has detailed some of the challenges he had in getting this done and some insights on how Apple restricts what MFI cable makers know about its Lightning connectors.

Pillonel spent hours opening up Apple cables, which he claims are built like tanks, to understand the system better and redesign the iPhone’s Lightning port. Pillonel spent a long time dismantling the PCB of Apple’s C94 port and has uploaded a snapshot of what it looks like.

The port was then reverse built on a PCB that was too large to fit inside the iPhone. However, he claims that after months of work, he could install it, charge and send data from the phone.

While we wait for the rest of the video, it’s unclear if Pillonel plans to sell the custom PCB or keep the project a secret. Even if the PCB were available as a kit, this would be a time-consuming upgrade that would negate any warranties. Furthermore, apart from the novelty of an iPhone with a USB-C port, there seems to be little benefit in doing just that.

However, it is a testament to Pillonel’s creativity and determination.