There are various exoskeletons and exosuits, possibly in the world, created to give support and strength to those in need. Recently, a new exoskeleton has been developed that is powered on Hydrogen.

Video footage was shared on YouTube by Alex Lab, where he is seen working in his garage, creating Hydrogen-powered artificial muscles. The product he creates was a sight on its own. The video shows details of how he develops his creation.

The Iron Man model is not very distinctive from various other exoskeleton suit projects, but this one is fueled by hydrogen is what makes it distinct. Additionally, Alex’s easy-going attitude in his video makes the whole process an extremely fun one.

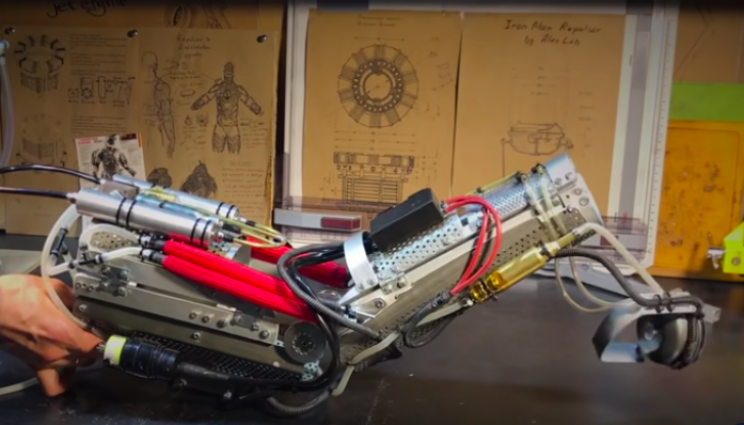

The artificial muscles that Alex utilizes are created by a rubber tube inside a nylon braid. As he fuels the ‘muscle,’ the rubber tube expands, fuels, and the nylon braid along with it.

It literally moves like a muscle, increasing and contracting just as the actual ones do. Typically, this sort of movement in exoskeleton muscles is made through compressed air. However, Alex chose to use hydrogen for his project.

Water is electrolyzed in a contraption that’s modeled to match Iron Man’s arc reactor, and the gases created as a result by this method are what end up powering the muscles.

Alex tests how the rubber tube and nylon braid are effected, Alex progresses in the direction of placing braids and 5 tubes together, joining them into an arm to observe how they manage to work as one.

Combined, they work amazingly and can hold up to 33 lbs (15 kg). Alex confirms that point by lifting a radiator completely with the exoskeleton’s strength.

By utilizing hydrogen, all of the actions are less noisy and simplified than when working with a usual air compressor. The main problem lies with fire, as the hydrogen system is at risk of being flammable; none the less, Alex works through these risks and how to dodge them in his video.