The journey towards establishing a lunar settlement is riddled with challenges, but Incus, an Austrian company, is on a mission to tackle a vital aspect: waste management on the Moon. Their innovative approach involves recycling waste into valuable components, eliminating the prospect of leaving litter on the lunar surface.

Space missions come with their fair share of waste, leaving behind discarded components designed to endure the harsh conditions of space. Incus, headquartered in Vienna, sees a golden opportunity to transform this waste using cutting-edge 3D printing technology. Their pioneering method, Lithography-based Metal Manufacturing (LMM), utilizes a mixture of metallic powder and a binding agent solidified by ultraviolet light exposure. Incus is moving towards a sustainable solution for space debris by repurposing these abandoned materials.

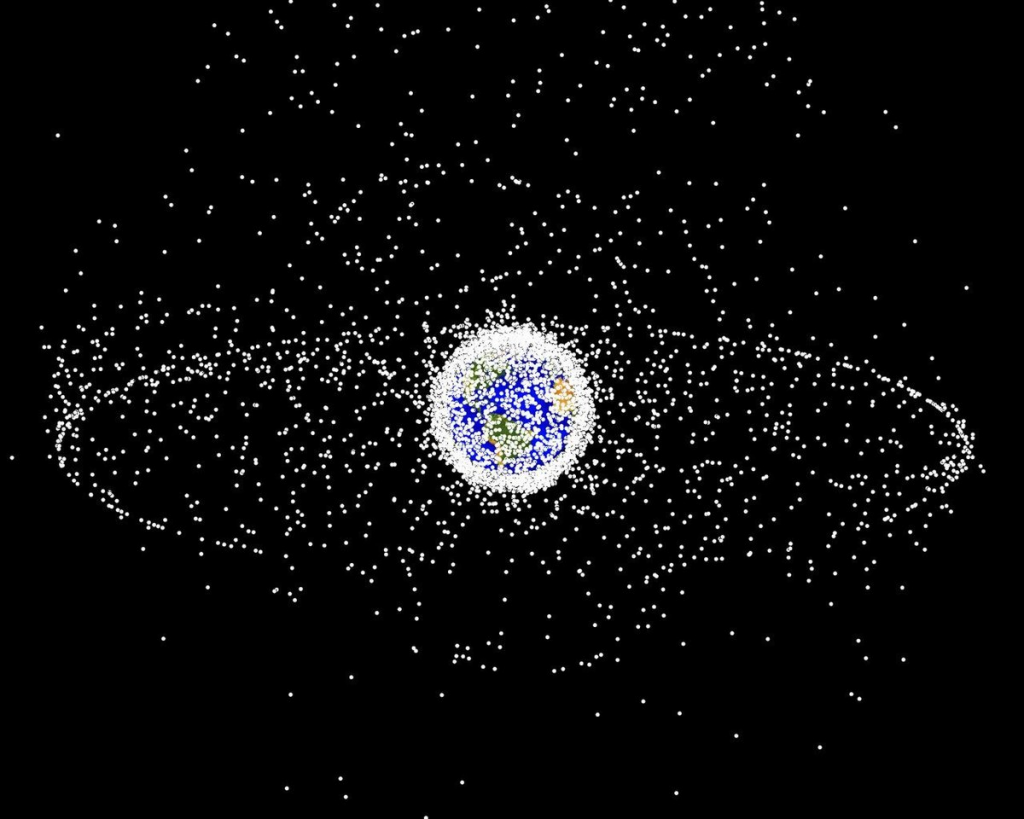

In collaboration with the European Space Agency (ESA), Incus is elevating its vision to new heights. Their plan involves sourcing materials for the 3D printing process from defunct objects like rovers, landers, and spacecraft. This ingenious approach addresses the growing concern of space junk and tackles a significant hurdle – lunar dust.

Lunar dust presents a unique challenge that could disrupt the binding process and jeopardize Incus’ endeavors. To tackle this issue head-on, Incus partnered with the ESA to assess the impact of lunar dust on their innovative approach. They simulated lunar dust and incorporated varying proportions into the metallic powder, conducting meticulous tests.

The collaborative effort shed light on the effects of higher lunar dust concentrations on the viscosity of the feedstock. However, this obstacle proved surmountable through adjustments in binder ratios. Incus’ CEO, Gerald Mitteramskogler, hailed the project’s success, emphasizing its ability to utilize recycled powder for the feedstock material and establish a sustainable zero-waste workflow.

Incus envisions applying its approach to various materials, including precious metals. While they’ve made significant strides, they acknowledge the need for further refinements in processing iron and steel and exploring the implications of elevated lunar dust concentrations – a pursuit the ESA is set to support.

Martina Meisnar, ESA’s technical officer, emphasized the relevance of such innovations in the context of lunar exploration. She noted that amidst the challenge of establishing a Moon base, the concept of in-situ resource utilization (ISRU) gains momentum. According to her, manufacturing techniques like LMM hold remarkable potential to bolster this audacious undertaking.