Plastic is something that we just can’t get rid of properly. So much plastic waste is produced every day that it has created small floating plastic islands in the Ocean that threaten to eradicate marine life and affect the climate severely.

Out of the millions of tons of plastic produced in the US each year, only around 9 percent of it is actually recycled. This is because it is very different to recycle the material into something else.

However, a new research study being conducted by scientists at the Washington State University or WSU could help solve the problem. Scientists have developed a new chemical treatment that could turn common-use plastics into components that can be used to make jet fuel. Many similar studies have been carried out in the past but this new chemical treatment stands out in a way that it requires moderate temperatures and a short timeframe to carry out the process.

Researchers say that the process can convert plastic into jet fuel components in just one hour. The scientists were able to convert around 90 percent of the plastic into the components for jet fuel, and other hydrocarbons using a catalyst made from carbon and ruthenium. This process, coupled with some commonly used solvents, took place at around 220 °C or 428 °F. Which is comparatively better than other processes that take up to 500°C of temperatures.

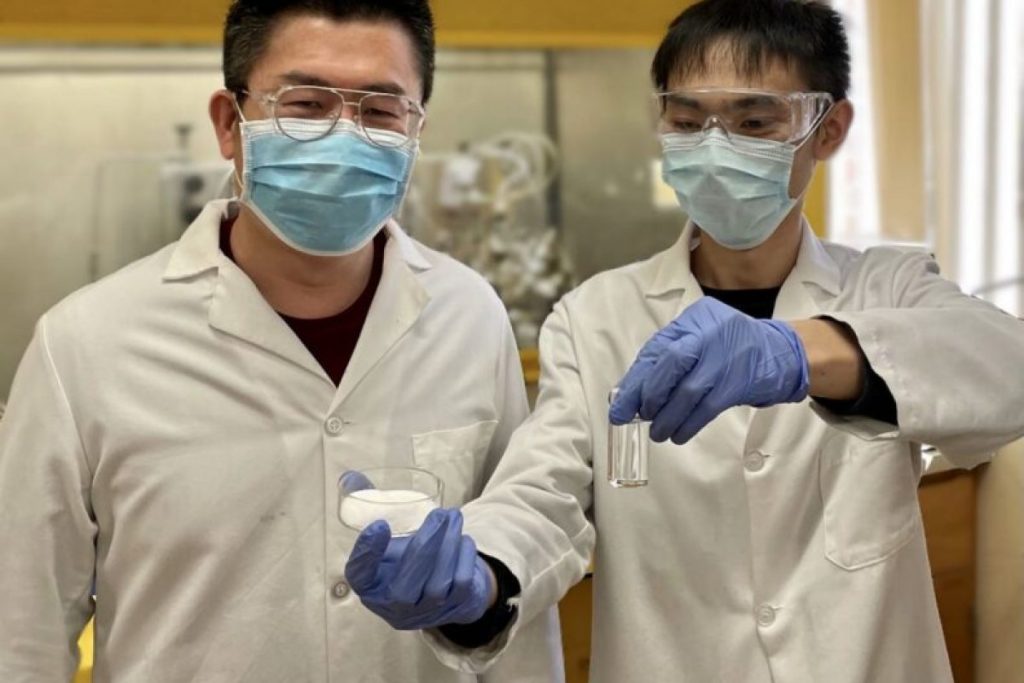

The researchers behind the method are the study authors, Hongfei Lin and Chuhua Jia. According to Hongfei Lin, “Depending on the market, they can tune to what product they want to generate. They have flexibility. The application of this efficient process may provide a promising approach for selectively producing high-value products from waste polyethylene”.

By simply changing the temperature, the amount of catalyst, or the timeframe, the process was able to produce components other high-value products as well. Researcher Lin explained that “In the recycling industry, the cost of recycling is key. This work is a milestone for us to advance this new technology to commercialization”.

The researchers are now looking for efficient ways to commercialize and scale up the process. They also hope to tackle other kinds of plastic waste as well. You can read up more on the study in the journal Chem Catalysis.