Water is frequently boiled, whether it’s a cup of tea in the kitchen or a power plant. Therefore, any improvement in this process’s efficiency will significantly influence the total quantity of energy consumed each day.

MIT researchers have discovered one such improvement, using surface treatments specifically suited for the materials used in these systems.

The boiling phase is characterized by two primary indicators: heat transfer coefficient (HTC) and critical heat flux (CHF). In general, there is a trade-off between the two, so anything that enhances one parameter weakens the other. Although both are important to the system’s performance, the team of scientists has discovered a technique to improve both features at the same time significantly.

“Both parameters are important,” says Song, “but enhancing both parameters together is difficult because they have internal trade-offs.”

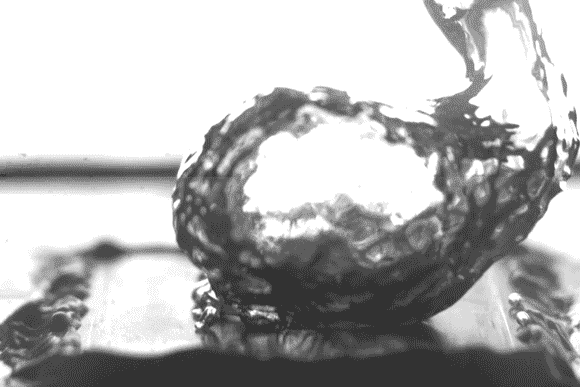

He explains that this is the case “because if we have a lot of bubbles on the boiling surface, the boiling is very efficient, but if we have too many bubbles on the surface, they can coalesce, creating steam. Lay it on a boiling surface. This film causes resistance to heat transfer from the hot surface to the water. If we have steam between the surface and the water, it interferes with the heat transfer efficiency and lowers the CHF value,” he says.

Moreover, to prevent film development, the researchers built 10-micrometer-wide indentations separated by around 2 millimeters in their work. However, this separation reduces the concentration of bubbles on the surface, which can limit fermentation efficiency. To counterbalance, the researchers used a much smaller-scale surface treatment, creating nanometer-scale bumps and ridges that increase surface area and speed up evaporation beneath the bubbles.

Cavities were created on the material’s surface at the centers of a series of columns in these experiments. These supports, in addition to the nanostructures, aid in the ejection of liquid from the bottom to the top, which improves the fermentation process by giving more surface area for water.

Song claims that when the three “tiers” of surface texturing—cavity separation, poles, and nanoscale texturing are combined, the boiling process is considerably accelerated.

“These micro-cavities determine the position where the bubbles rise,” he says. “But by separating these cavities by 2 millimeters, we isolate the bubbles and minimize bubble coalescence.”

Simultaneously, the nanostructures facilitate evaporation beneath the bubbles, and capillary action generated by the columns transports liquid to the bubbles’ base. This keeps a layer of liquid water between the boiling surface and the steam bubbles, allowing for the most heat flow.

While the recent study demonstrated that this type of surface treatment combination works and achieves the desired impact, Wang notes that “this work was done in small-scale laboratory conditions that could not easily be scaled up to practical devices.”

“Showing that we can control the surface in this way to get an improvement is the first step,” Wang says. “Then the next step is to think about more scalable approaches.”

This method may have some significant small-scale applications, such as thermal management of electronic equipment, which is becoming more essential as semiconductor devices shrink and controlling their heating capacity has become more crucial.

Even such applications will take years to develop as most electronics temperature management systems employ dielectric fluids rather than water. Because these liquids differ from water in terms of surface tension and other properties, the dimensions of the surface features must be changed accordingly.