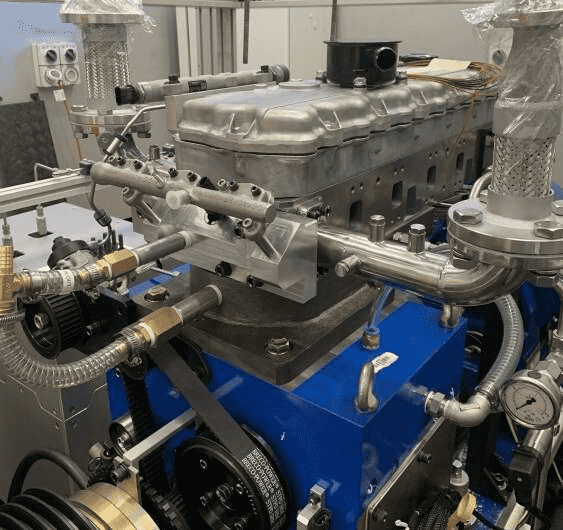

Engineers from UNSW Sydney have converted a diesel engine to work as a hydrogen-diesel hybrid engine. This development has reduced CO2 emissions by more than 85% in the process.

The team was led by Professor Shawn Kook from the School of Mechanical and Manufacturing Engineering who spent around 18 months in the process.

The researchers say that any diesel engine used in trucks and power equipment in the transportation, agriculture, and mining industries has the capacity to be retrofitted to the new hybrid system.

In a paper published in the International Journal of Hydrogen Energy, Prof. Kook’s team demonstrates that using their patented hydrogen injection system, CO2 emissions can be reduced to just 90 g/kWh—85.9% below the amount produced by the diesel-powered engine.

“This new technology significantly reduces CO2 emissions from existing diesel engines, so it could play a big part in making our carbon footprint much smaller, especially in Australia with all our mining, agriculture and other heavy industries where diesel engines are widely used,” says Prof. Kook.

“We have shown that we can take those existing diesel engines and convert them into cleaner engines that burn hydrogen fuel.

“Being able to retrofit diesel engines that are already out there is much quicker than waiting for the development of completely new fuel cell systems that might not be commercially available at a larger scale for at least a decade.

“With the problem of carbon emissions and climate change, we need some more immediate solutions to deal with the issue of these many diesel engines currently in use.”

This research was jointly done with Dr. Shaun Chan and Professor Evatt Hawkes. It was discovered that specifically timed hydrogen direct injection controls the mixture condition inside the cylinder of the engine. This resolves harmful nitrogen oxide emissions that were a huge hurdle in the commercialization of hydrogen engines.

“If you just put hydrogen into the engine and let it all mix together you will get a lot of nitrogen oxide (NOx) emissions, which is a significant cause of air pollution and acid rain,” Prof. Kook says.

“But we have shown in our system if you make it stratified—that is in some areas there is more hydrogen and in others, there is less hydrogen—then we can reduce the NOx emissions below that of a pure diesel engine.”

When compared to existing diesel engines, this has shown an increase in efficiency by 26%.

The system is aimed for commercialization in 12 to 24 months.