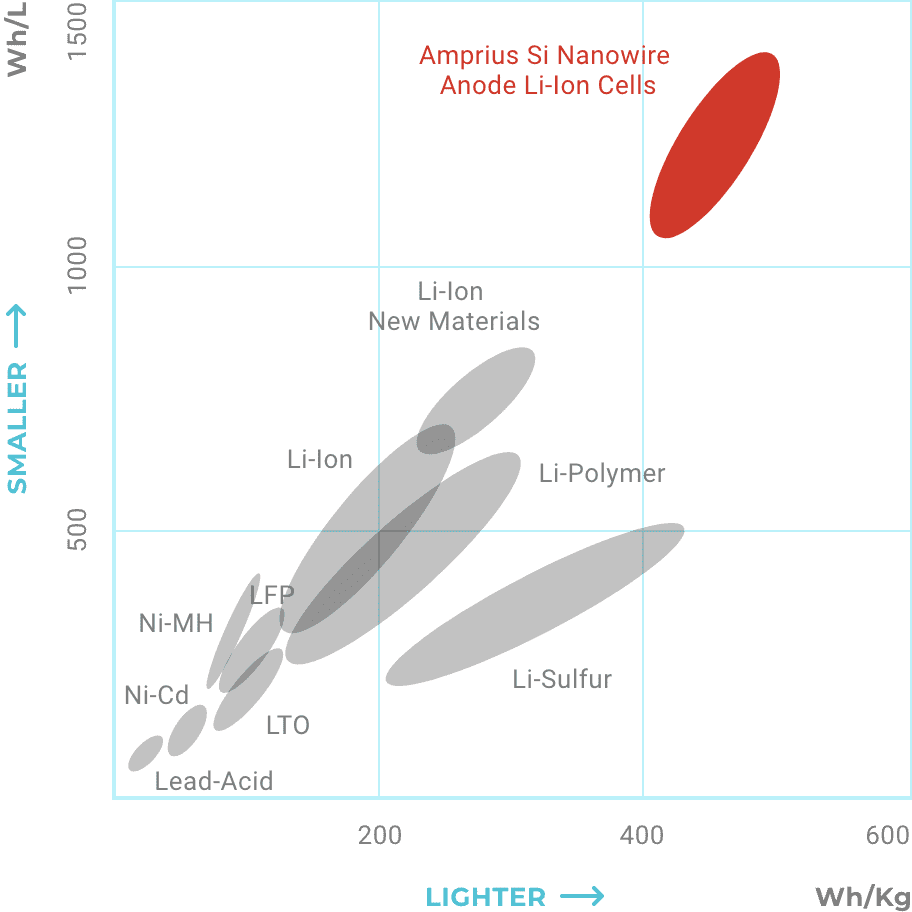

Amprius, a Californian Company has worked on the development of the highest-density batteries and the company has shipped a very first batch of what it claims are the most energy-dense lithium batteries available today. These batteries hold 73% more energy than Tesla’s Model 3 cells by weight. Moreover, they consume 37% less space.

According to Empower, Tesla’s Model 3 cells hold around 260 Wh/kg and 730 Wh/I. But in terms of energy and energy density, these new Amprius cells are a significant step up. They can hold 450 Wh/kg and 1150 Wh/I. According to the company, the concealed number of cells delivered to “an industry leader of a new generation of High-Altitude Pseudo Satellites” is giving it bragging rights for having the highest energy density cells available in the battery industry today.

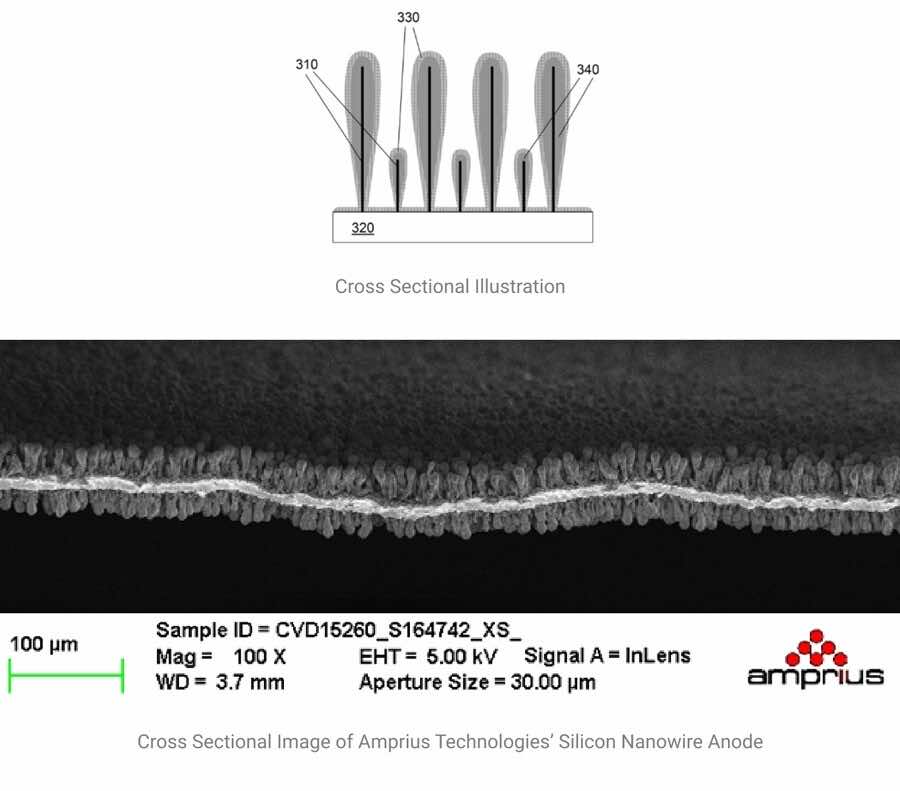

The battery’s impressive performance is due to its silicon nanowire anode technology. When a lithium-ion battery is charged, an electron is pulled from the lithium atom sitting at the cathode. This enables them to move across to the anode via external wiring since the electrons cannot pass through the electrolyte or separator between the anode and cathode. Positively charged lithium ions find an electron and become embedded in what’s typically a graphite lattice at the anode.

This graphite lattice is actually replaced with silicon nanowires. Silicon can store some 10x more lithium than graphite. But there is a drawback that silicon tends to swell and crack, thus reducing the cell’s life. But when the silicon is transformed into porous nanowires, arranged as a kind of forest of wires, the silicon is then able to resist cracking and can avoid swelling.

The company says that the silicon nanowires are rooted into the substrate of the anode. In this way, the life cycle of cells becomes “excellent” and is “continually improving”. Moreover, the anode is the part of the cell that needs to be changed, the remaining parts can be produced using existing manufacturing methods.

Actually, energy density and specific energy are two measures on which the battery needs to compete. Moreover, safety, charge/discharge rates, and thermal performance will also play a big role.

The company will soon choose a site, on which a mass production facility will be built. It will bring economies of scale that may make this technology relevant in the EV market. Nawa Technologies says it has developed a way to manufacture vertically aligned carbon nanotube electrodes cheaply. It is claimed that such an effort would lead to 300 percent improvements in today’s lithium batteries.

Source: Amprius