ITER, the world’s largest fusion experiment, is now even more close to coming into existence thanks to having reached southern France. They have gotten the special magnets that are needed for the core of its reactor. This event signifies the end of a long design process lasting two decades and covering efforts in three different continents for fabrication.

In the search for carbon-free energy, nuclear fusion comes up as an alternative which could be promising: it presents the possibility of having energy when needed. Recent progress has shown that it is possible to get energy from nuclear fusion; more than 30 countries are participating in the International Thermonuclear Experimental Reactor (ITER) project in France. ITER uses a tokamak approach where hydrogen fuel is injected into a torus-shaped vacuum chamber— heated to produce plasma and sun-like conditions with a temperature of 150 million degrees Celsius at which fusion reactions take place.

Massive superconducting magnets are needed to keep this plasma inside the reactor’s walls. Niobium-tin and niobium-titanium are used in ITER’s design as magnet materials. To make these coils superconducting, they are electrically charged and cooled to a mere four degrees Celsius above absolute zero.

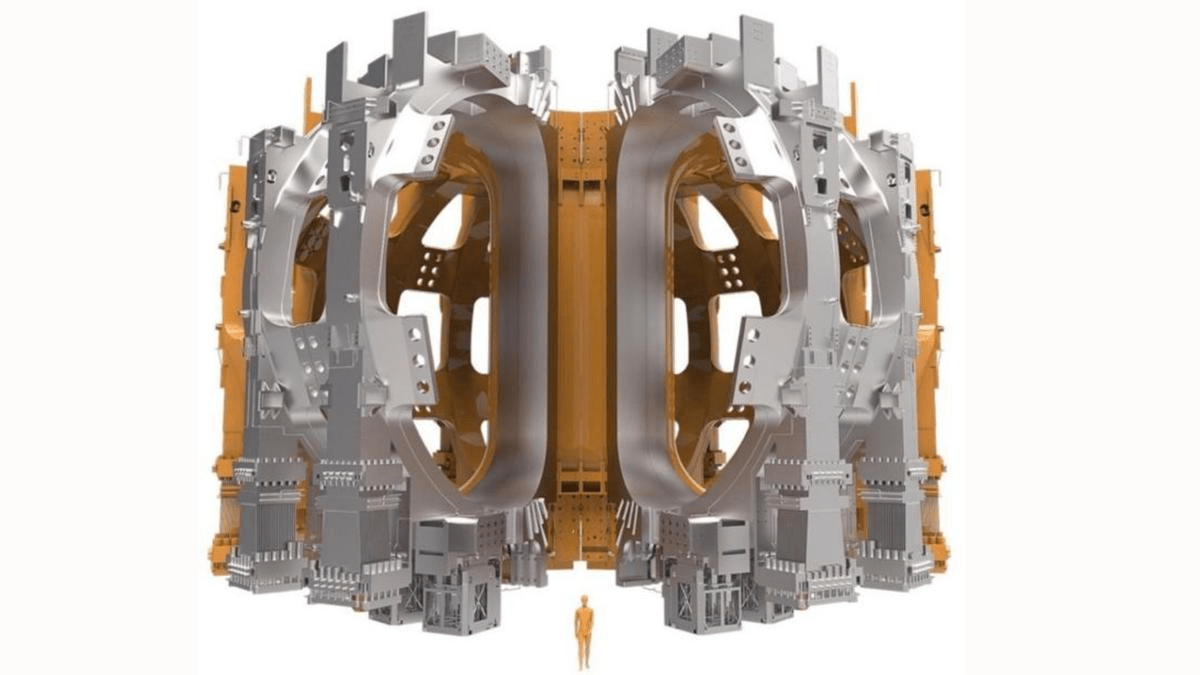

ITER’s magnetic system comprises three components to create the magnetic cage needed to confine the plasma. Eighteen D-shaped toroidal magnets form the outer donut shape, while six additional magnets circle the tokamak horizontally to control plasma shape. A central solenoid generates current in the plasma with energy pulses. The plasma current will peak at 15 million amperes, setting a record for tokamaks globally. The magnetic field generated will be 250,000 times stronger than Earth’s, with a total magnetic energy of 41 gigajoules.

Each toroidal magnet stands 55 feet tall, 30 feet wide, and weighs 360 tons. The fabrication process began with niobium-tin strands wound with copper and inserted into a steel jacket, forming a conductor. Over 54,000 miles of these strands were required. The conductor was shaped into double spiral trajectories, heated, and inserted into stainless steel plates, then insulated, laser-welded, and injected with resin. Seven such double pancakes formed a winding pack, the core of the magnet, encased in a 200-ton stainless steel structure to withstand plasma forces and fusion energy.

ITER’s advancement marks a significant leap towards realizing a sustainable and powerful energy source, harnessing the immense power of fusion.