Tesla is encountering significant challenges in the production of its recently announced Cybertruck, with insiders revealing that the main bottleneck lies in manufacturing the vehicle’s next-generation 4680 lithium-ion battery cells. Approximately 1,360 of these cells are required for each Cybertruck, and Tesla is exploring a novel approach using dry-coating electrodes to expedite and reduce the cost of the production process.

Dry coating electrodes for anodes and cathodes is a proven method for small energy storage devices, but Tesla is attempting to pioneer its application on a mass scale and at a high speed, according to battery technology consultant Yuan Gao. Scaling up this process to meet the demand for entire electric vehicles poses a significant challenge that Tesla has yet to overcome.

The company aims to produce 250,000 Cybertrucks, necessitating nearly one million 4680 cells per day. Presently, Tesla’s Giga Texas factory is reportedly only producing at a rate sufficient for 24,000 Cybertrucks annually.

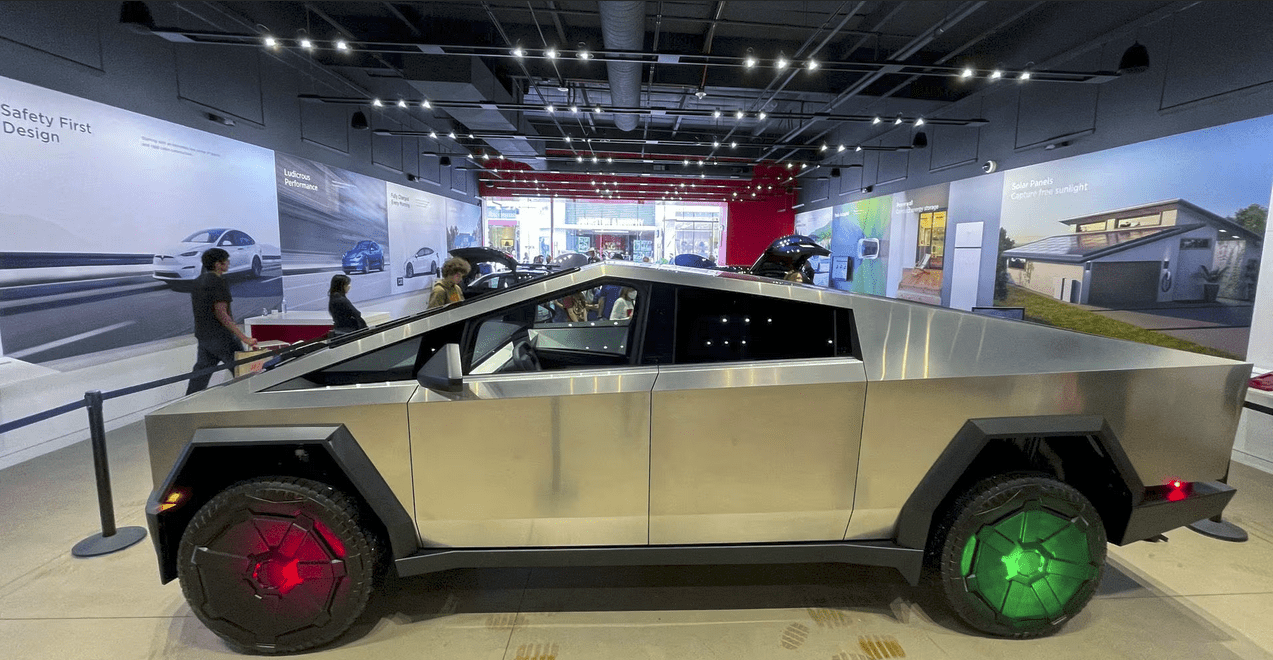

While some insiders express optimism, stating that if Tesla can “crack the code,” production speed will increase, the company faces hurdles beyond battery cells. The manufacturing process of bending the thick stainless steel panels that form the Cybertruck’s unique exterior has proven challenging. Moreover, the exact number of Cybertrucks delivered remains unclear, with reports suggesting only a dozen or so trucks were handed over following a chaotic delivery event.

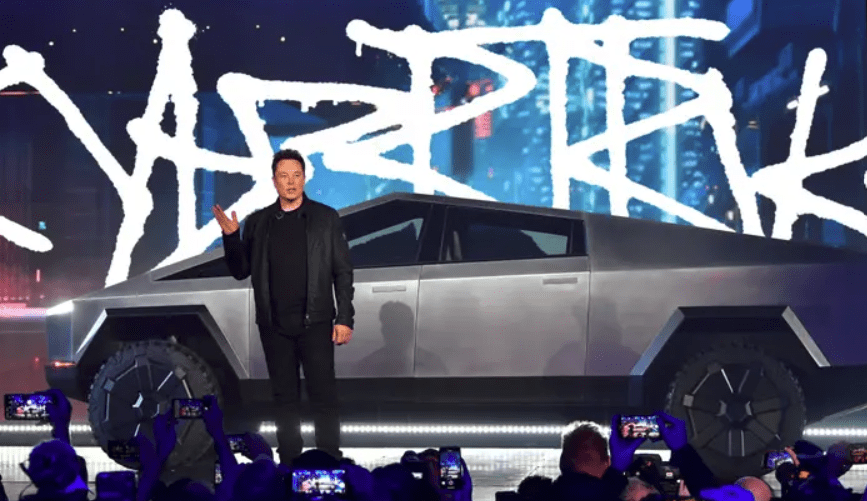

Tesla CEO Elon Musk acknowledges the formidable task ahead, predicting that substantial production volume for the Cybertruck may only be achieved by 2025. Musk has openly recognized the challenges, stating during a Q3 earnings call that they “dug our own grave with the Cybertruck” and emphasizing the enormous obstacles in achieving volume production and making the Cybertruck cashflow positive.

The overall picture suggests that Tesla is grappling with multifaceted challenges, not only in the innovative battery cell production but also in the complex manufacturing processes associated with the Cybertruck’s distinctive design.

“We dug our own grave with the Cybertruck,” Musk said during Tesla’s Q3 quarterly earnings call earlier this year. “I do want to emphasize that there will be enormous challenges in reaching volume production with the Cybertruck and then making the Cybertruck cashflow positive.”