Say hello to Cirin – a mini race car that has been modeled after the mid-1950s Formula 1 cars. It has been created through state-of-the-art-construction methods along with 5 meters of looped elastic, which enables it to travel 152 meters at a speed of up to 30 mph.

Crin is designed by a trio of students, Max Greenberg, Ian Cullimore and Sameer Yeleswarapu, at the Art Center College of Design located in Pasadena, California. The team came up with this amazing car to compete in the school’s Formula E Race. Formula E Race is a yearly event where teams compete from all over the world by pitting the custom-made rubber-band powered cars against one another.

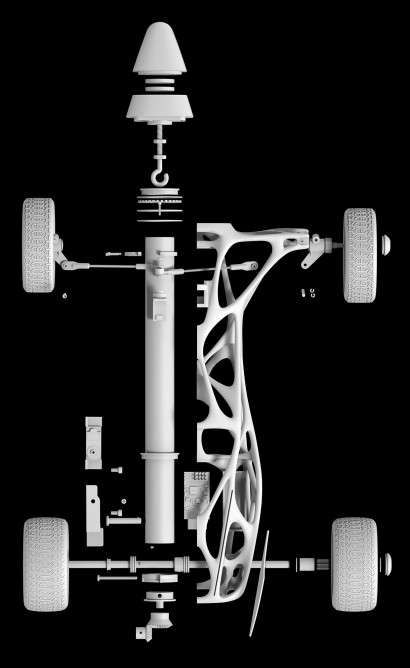

SolidWorks was used for the arrangement of Cirin’s mechanical layout which was followed by a couple of prototypes that were created and tested. The final product’s construction was sponsored by 3D printing company SolicConcepts. The company provided the one-piece main body while the construction was carried out by laser sintering to melt consecutive layers of nylon powder selectively.

The bio-truss structure of Cirin was inspired by the internal structure of birds’ wing bones and provided a rather high strength-to-weight ratio. This design can endure high torsional stress being delivered by the tightly wound elastic and the construction involved very few fasteners.

Cirin was powered by a single elastic band wound into 203mm loops and ran between the 2 eye bolts within a tube made of carbon fiber. One of the eye bolts was located at the car’s nose while the other was located at the rear axle in the geared drive mechanism. Once the nose cone is removed, the band can be wound manually and then held in place until go-time is announced by a servo motor. Steering system makes use of the second servo. The steering system and braking system is controlled via the radio remote control.

The cost of construction minus the 3D printing done by SolidConcepts is $500. The car was not able to win the race, however, the team was awarded the design, build and approach award!