Robots are no strangers to construction sites, but a new entrant called Charlotte could push automation to an entirely new level. Designed to 3D print entire homes at lightning speed, Charlotte is billed as being able to construct a 2,150-sq-ft (200-sq-m) house in just 24 hours operating at the pace of roughly 100 human bricklayers.

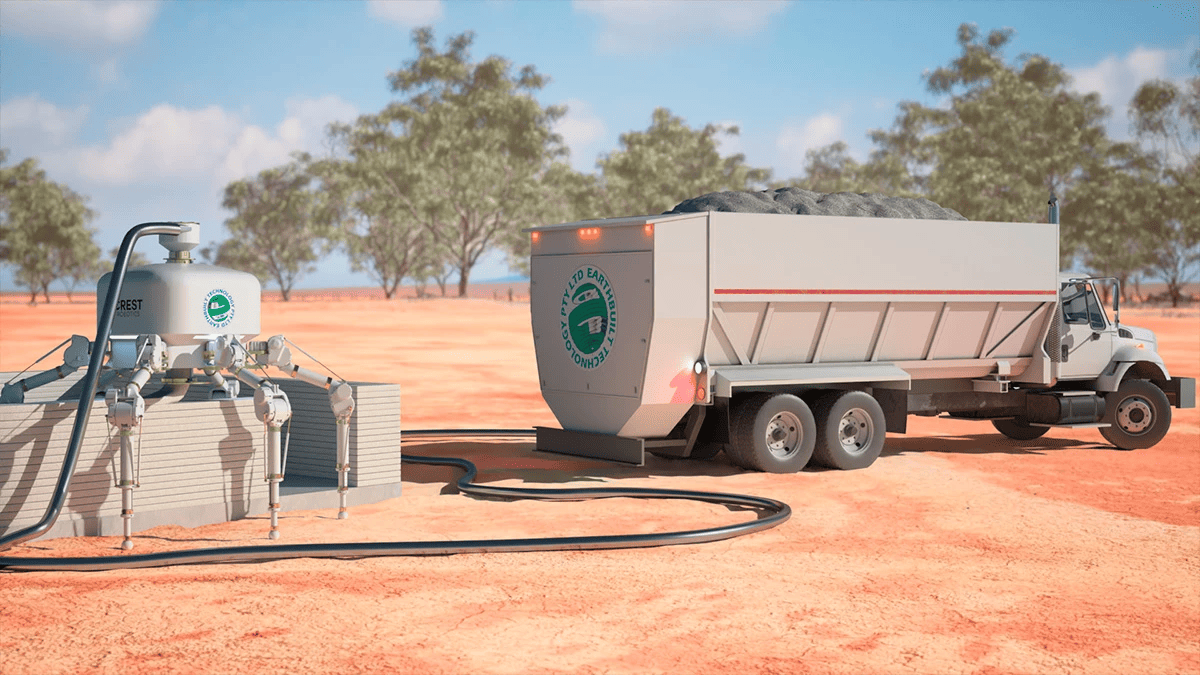

Charlotte is the brainchild of Crest Robotics in partnership with Earthbuilt Technology, which has developed an eco-friendly building material made from sand, waste glass, and crushed brick. Instead of performing individual tasks like rebar tying or panel assembly, the robot extrudes this compressed mix in successive layers, gradually “printing” walls and structures in a continuous process.

Its bio-inspired spider legs let it move and raise itself autonomously as the build progresses meaning the entire house can be completed by a single machine without external scaffolding or support.

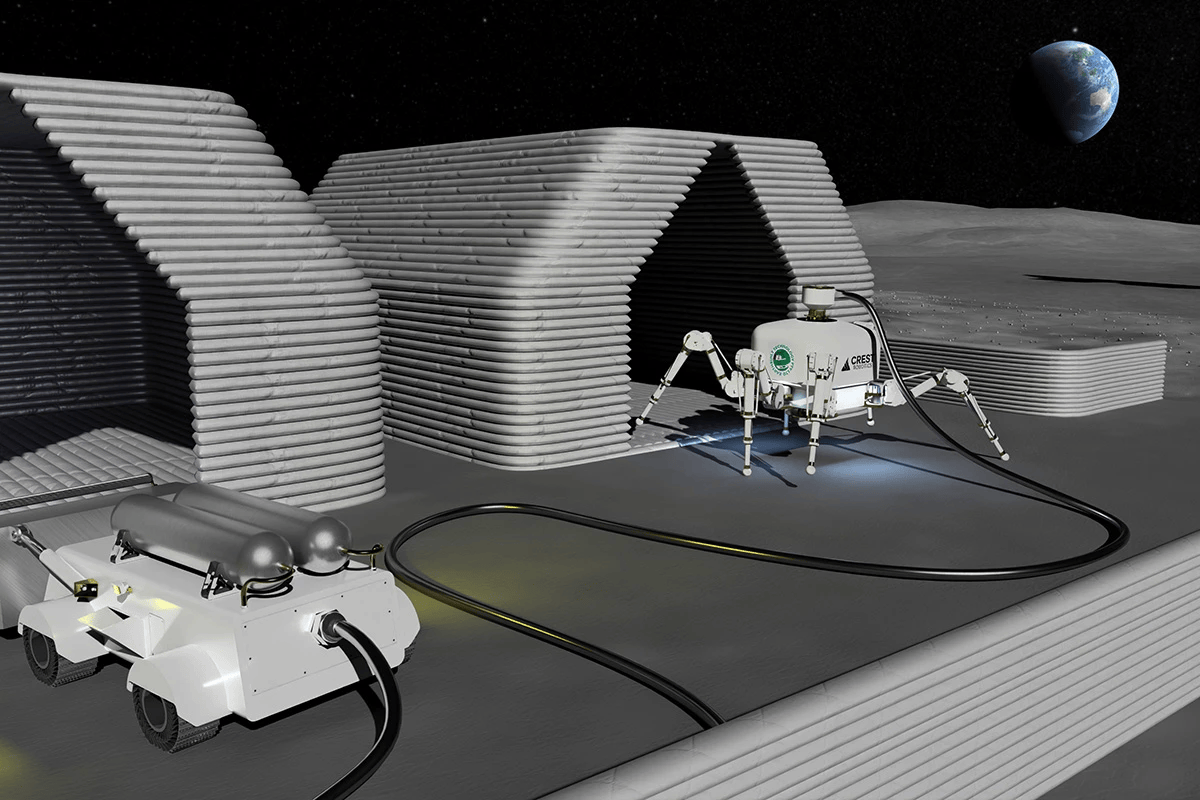

Although Charlotte is still in development and several years away from its first full-scale house, a prototype has already been showcased at an exhibition. Beyond housing, its creators even envision future use on the Moon, where its compact, versatile design and autonomous capabilities could help assemble lunar research bases using locally available materials.

The promise is more than just futuristic. By producing floodproof and fireproof structures quickly and cheaply, Charlotte could help tackle housing shortages across the globe. If its Earthbuilt materials are sourced locally, the system could also dramatically cut the carbon footprint of construction.

That said, the robot currently supports simpler designs and may not suit all climates, markets, or aesthetic preferences. But for regions struggling with housing deficits, labor shortages, and rising construction costs, Charlotte represents a potential game-changer.