Scientists have taken inspiration from the defense mechanisms found in Lotus leaf plants. They came up with an innovative idea known as ‘High Throughput Laser Texturing of Self-Cleaning and Antibacterial Surfaces,’ or simply known as the ‘TresClean” project. This project made breakthroughs and is looking to start the production of self-cleaning sheet metal on an industrial scale for the first time!

This brand new technology will be initially used in the creation of antibacterial surfaces for the food production industry. This can dramatically increase productivity and reduce costs in biological food product factories that are creating products like milk, tomato sauce, and yogurt.

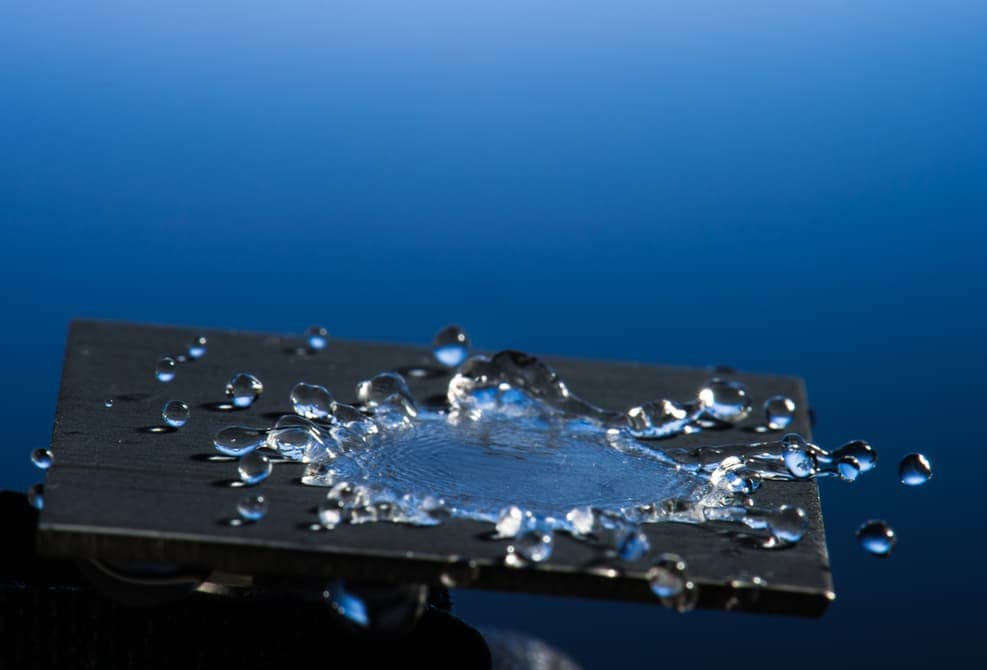

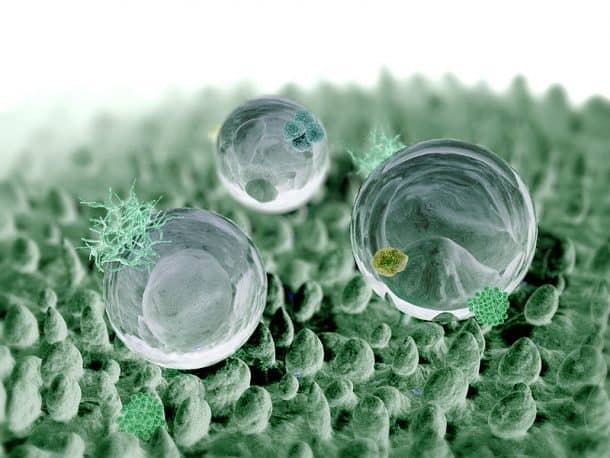

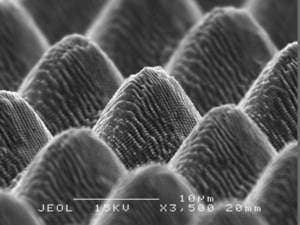

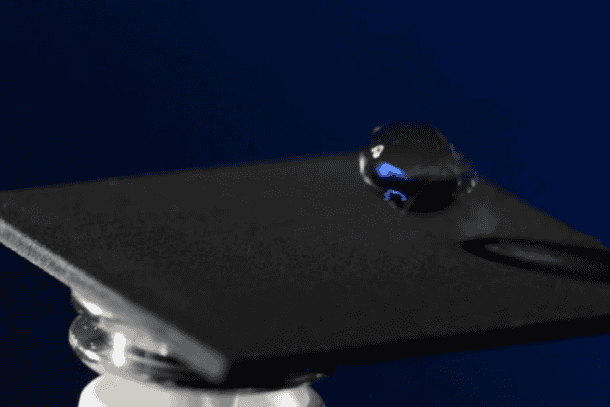

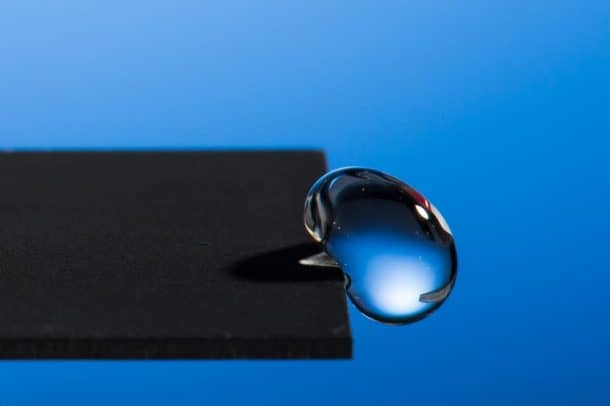

TresClean technology uses a high-power laser cutting device to create a specifically tailored rough microtopography on sheet metal that is similar to the surface of the Lotus leaf. The resultant roughness causes the liquids to ‘bounce off’ and create miniature pockets of air to minimize the contact area between the surface and a liquid.

Professor Luca Romoli, the project coordinator of TresClean project, elaborated on the phenomenon and said that this works in the same way as a Lotus leaf to keep itself clean. It doesn’t require any cleaning product or externally applied chemical for this purpose. The jagged and roughed up surface is enough to keep water in the form of spherical droplets while stopping it from spreading and splashing. Moreover, it does not give bacteria a chance to stick and thus, its contact with the metal surface and the liquid is reduced by over 80%. It can lead us to the creation of anti-bacterial metals as well.

This self-cleaning approach is already available for many expensive plastic components, but it is a first for metals. Metal surfaces are given a texture using industrial photonics devices that comprise of high to average power ultrashort-pulsed lasers. These lasers are used in combination with high-performance scanning heads that use an innovative beam delivery method to enable the movements of up to 200 m/s speed.

TresClean is quite innovative as it can achieve this surface texturization process very quickly. It can cut areas of 500-square-cm in less than 30 minutes which is indeed a great speed. Earlier production methods made laser-etched metal at a rate of 1-square-inch in 1 hour, whereas TresClean approach was able to produce 1000-square-cm in the same period, thus making this technology 156 times quicker than the previous techniques.

Romoli said that he thinks that he could have the products ready within 2 years. Initially they are aiming this product for the food industry, and hope that it can make a significant impact on productivity. This is done because containers like vats in milk factories are usually cleaned every 6-8 hours to avoid the exponential growth of bacteria. By using this technology, they can increase productivity and cut down on the time wasted on the cleaning process of equipment by a great deal. This will also reduce energy consumption as a result of fewer cleaning phases, thus making food production quicker, safer, and more profitable

Professor Romoli said that he can see long-term possibilities and applications of this technology in other sectors. He said that it is quite plausible that any metal that needs to avoid the formation of bacteria can use the TresClean product. Variety of industries are using a multitude of products such as medical cutting tools, sterile surfaces, dishwashers, or even saucepans to employ this technique so as they may improve their metal cleaning techniques.

This project has been coordinated by the UNIVERSITÁ DEGLI STUDI DI PARMA; a consortium that consists of members from Italy, France, Germany, Spain, and the UK. It has received a grant of whopping EUR 3,363,091.25 from the Photonics Public Private Partnership under the H2020 Industrial Leadership funding calls, and thus is all ready and rearing to become a reality!

Can you suggest any industry or application that can be improved by using this state of the art technology? Let us know in the comments’ section below!