Clinicians at the Claudius Regaud Institute and Toulouse University Hospital have successfully performed a nose transplant with an implant grown on the patient’s own forearm.

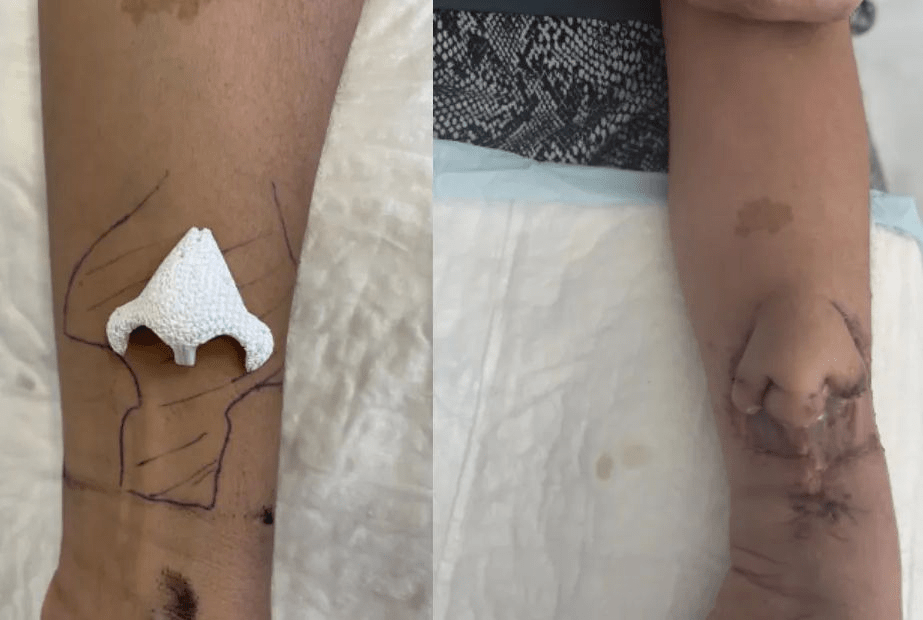

The patient had lost most of her nose to cancer in 2013. She agreed to become the test subject for a new approach. The process entailed a 3D bioprinted nose grafted onto her forearm, where it was grown for two months before being removed, revascularized, and successfully implanted onto her face.

For more than four years after her cancer treatment, the patient lived without a nose, due to a failed skin flap grafting procedure.

The surgeons collaborated with a clinical team from Belgian medical device manufacturer CERHUM to develop a biomaterial-based, nose-shaped structure. This was then implanted onto and fostered on the patient’s arm, and once ready, it was revascularized through ‘anastomosis’ microsurgery.

This process ensured that her forearm vessels connected to those on her temple so the implant wouldn’t be rejected.

According to the surgical team behind the procedure, it was unique and “had never before been performed on such a fragile and poorly vascularized area.” They reported last month that the patient had undergone hospitalization and three weeks of antibiotics, and everything was “doing very well.”

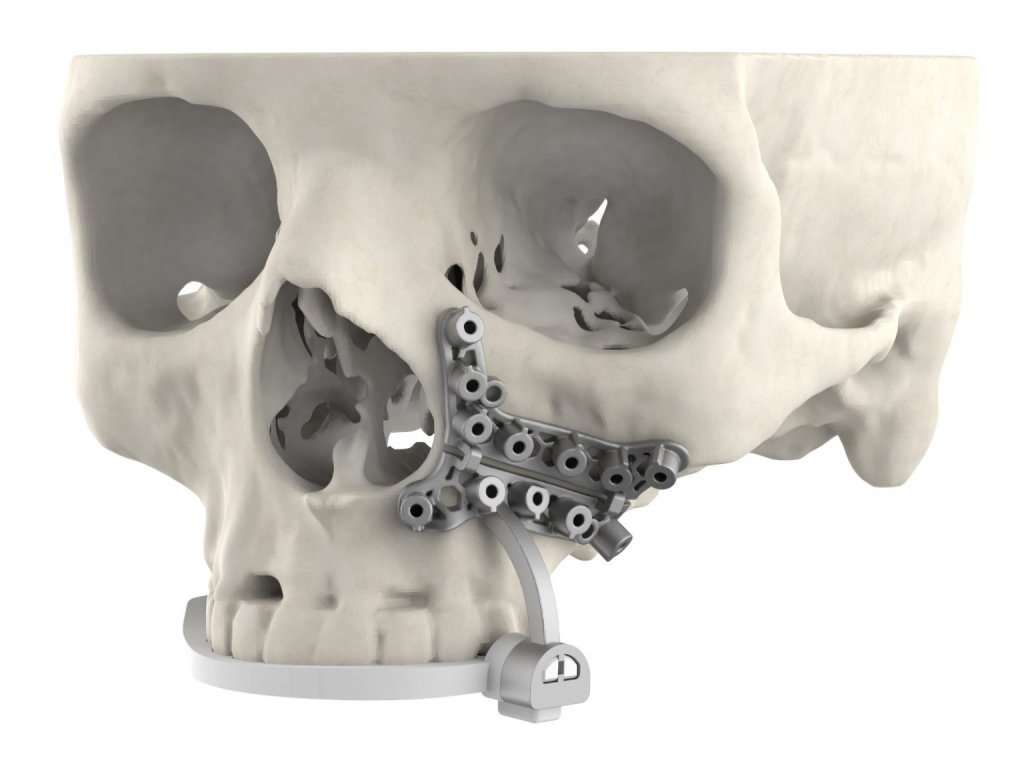

The process employed CERHUM’s proprietary MyBone maxillofacial implants, which gained approval for use on European patients earlier this year, the firm says it has already produced thousands of devices for R&D, Contract Development and Manufacturing Organization (CDMO), and implantation.

These implants are based on a fully-biocompatible bioceramic, which can be 3D printed in a way to adjust with the desired porosity and their geometries to be customized to patients. The devices are made from hydroxyapatite, a component of bone that’s known for its osteoconductive and osseointegration properties, which promote their colonization by blood vessels in-body.

CERHUM’s technique is less risky than autografts and allografts. It also states that its bioceramic has “better biocompatibility than most synthetic materials.” The firm also claims its devices promote faster healing than standard implants and entail fewer surgeries.

Last year, 3D Systems revealed a titanium and nylon-based hybrid maxillofacial surgical guide, which allows for occlusal registration.

Earlier, the Québec Industrial Research Centre also used a GE Additive Arcam Q10 Plus 3D printer to develop patient-specific lower jawbone implants. The organization worked with craniomaxillofacial surgeons at the University Hospital of Quebec, on applying 3D printing to transform the design-to-manufacture process of such devices.