In a time where automation is rapidly transforming how industries operate, a promising new player has stepped into the spotlight.

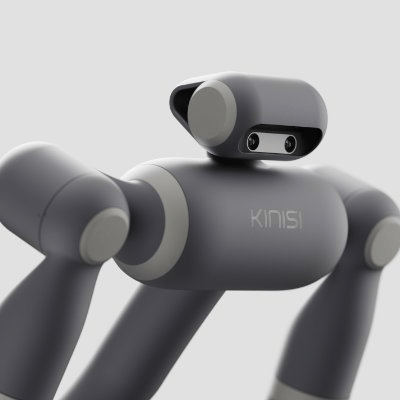

Kinisi Robotics, a U.S.-based startup founded in 2023 has come up with its latest innovation: the KR1 humanoid robot. Engineered for precision, strength, and adaptability, KR1 is designed to perform a wide range of pick-and-place tasks with human-like dexterity blending muscle and finesse in a single mobile unit. This breakthrough comes at a pivotal moment when labor shortages and operational inefficiencies are forcing industries to rethink their workforce strategies.

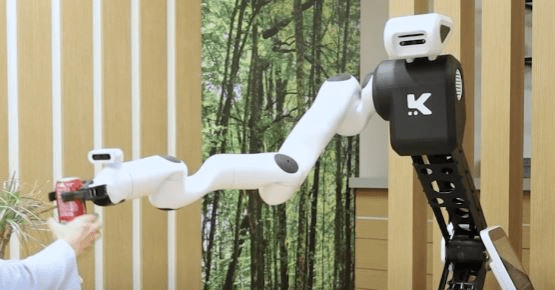

Kinisi Robotics built KR1 not just as a robotic helper but as a true industrial co-worker. With the ability to lift up to 22 pounds and handle delicate goods without damage, KR1 targets one of the most challenging aspects of warehouse logistics: the need for reliable, safe, and fast handling of diverse inventory. Equipped with a wheeled base, the robot navigates warehouse floors with agility, while hot-swappable batteries and auto-docking capabilities allow it to operate continuously for up to eight hours. It’s designed to function alongside human workers, making operations more efficient without requiring sweeping infrastructure changes.

What sets KR1 apart is not just its mobility or payload capacity it’s the intelligence built into its core. Rather than relying on cloud-based processing, KR1 operates autonomously, using onboard computing to analyze, learn, and act in real time. This makes it resilient in environments where internet connectivity may be limited or inconsistent, ensuring uninterrupted performance and enhanced data privacy. Its local learning architecture also means faster adaptation, particularly valuable in dynamic environments where every second counts.

A key innovation behind KR1’s evolution is Kinisi’s “data flywheel” system. With every task it performs, each KR1 robot shares interaction data across the entire fleet, creating a networked intelligence that improves performance on the fly. As robots learn from each other, deployment becomes quicker and more efficient. In addition, KR1 supports imitation learning, a process where operators can simply demonstrate a task instead of programming it manually. This user-friendly feature enables rapid reconfiguration across changing workflows, democratizing automation for businesses of all sizes.

Ease of integration is another crucial strength. KR1 is built for plug-and-play deployment, meaning companies can incorporate it into existing warehouse operations without the need for complex retrofitting or system overhauls. Its ability to avoid real-time obstacles, adapt to new tasks, and work safely around humans makes it ideal for sectors that require flexible and intelligent automation ranging from retail and logistics to maintenance and light assembly.

Brennard Pierce, the founder and CEO of Kinisi Robotics, emphasized this vision in recent statements, reinforcing the company’s goal to make automation more accessible, scalable, and impactful. According to Pierce, “Our mission is to streamline warehouse workflows and solve today’s labor challenges with fast, flexible robotic systems.”