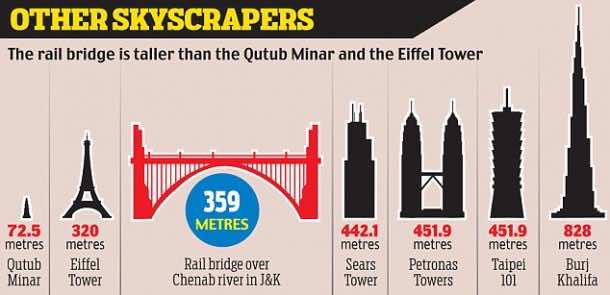

Put your engineering hats on readers, we are about to dive into the construction of an engineering wonder that is being carried out in Reasi district of Jammu and Kashmir. The Chenab Bridge is an arch bridge that is under construction and spans the Chenab River between Kauri and Bakkal. Once completed, it will be 1,315m in length and shall feature a 480m trussed arch space with a height of 359m above the river Chenab and a 650m long viaduct located on the Kauri side. The end of construction will set two world records for the steel railway bridges; the height above the valley floor and the clear span across the valley gorge.

B.D. Garg, Chief administrative officer of the project in Northern Railway said, “The weather in the region gets worse in no time due to the Himalayan range. At such height, the bridge can lose shape due to strong winds, which is why, we have made a unique design for this project. This bridge project has been allotted to Afcons India Private Ltd, and we have also hired consulting agency from Denmark.”

The bridge shall feature a huge steel arch, the first of its kind in India while the country has no codes or design guidance for such a massive structure. That is why experience drawn from other similar projects worldwide is being put into practice for this project. BS: 5400 is being employed as the basic guideline for the design and subsequent construction of the bridge. The deep Chenab river valley under the bridge experiences high wind pressures and to tackle this Force, Technology Laboratory based in Norway conducted a number of wind tunnel tests to understand completely the effects of wind speed along with gust buffeting and static force coefficients. The bridge has been, therefore, designed to be able to tackle wind speeds of around 260km/h. The dangers of an earthquake were also kept in mind when designing the bridge.

The bridge will sport 17 spans along with a 469-meter long main arch span across the Chenab River and viaducts on both sides. The main span of the bridge will feature two 36m long approach spans. The idea is to build the bridge as a two ribbed arch that feature steel trusses made of steel boxes that are filled with concrete. The structure will be supported via two 130m long and 100m high pylons on either end supporting the bridge via cables.

Steel was chosen as the primary construction material because it can resist temperatures of -20C and withstand speeds of more than 200km/h. The bridge, for the sake of security and safety, is being built with 63mm thick special steel that is blast-proof. The concrete pillars of the bridge are also being designed so that they can survive explosions.

Aerial security will be provided to the bridge. An online monitoring and warning system is to be installed on the bridge to safeguard passengers and trains during critical conditions. The bridge is to be painted with a special paint that resists corrosion and can last for 15 years.

This surely will be an engineering wonder once it is completed.