According to the United Nations, 783 million people in the world have no access to clean drinking water. While the fresh water supply continues to run out, researchers have been working on ways to convert salt water into fresh drinking water. A team of scientists at the University of Manchester, UK has developed a graphene-based sieve that can remove salt from seawater to get clean drinking water. The research was published in the journal Nature Nanotechnology.

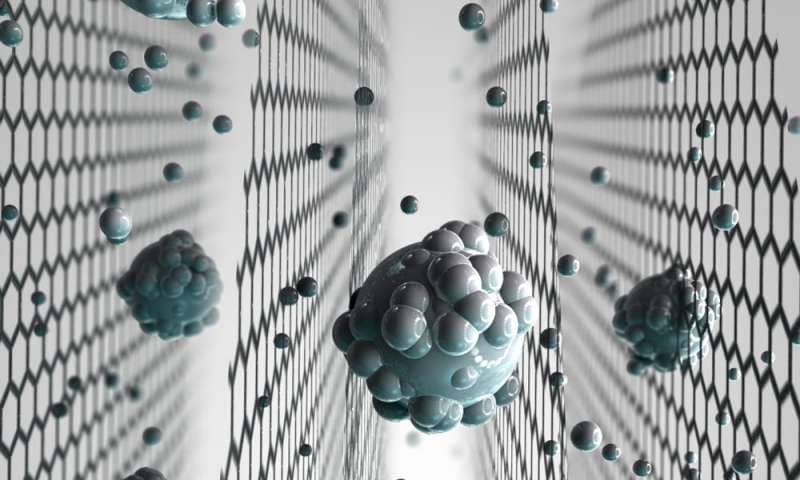

Graphene is a single layer hexagonal lattice of carbon atoms. It is known to be the lightest and the strongest material to exist. Its strength and electrical conduction properties have made it one of the most valuable materials in a variety of applications. The research team led by Dr. Rahul Nair has used a chemical derivative graphene oxide in developing the seawater sieve.

It is hard to produce graphene in large quantities, but graphene oxide is different. Dr. Nair says, “Graphene oxide can be produced by simple oxidation in the lab. As an ink or solution, we can compose it on a substrate or porous material. Then we can use it as a membrane. In terms of scalability and the cost of the material, graphene oxide has a potential advantage over single-layered graphene.”

Graphene oxide membranes have already been successfully used to sieve out nanoparticles, organic molecules and large salts from water. The common salts in seawater are, however, so small that they require even smaller holes to be sieved through. The graphene oxide membranes have been observed to swell when submerged in water. This allows smaller salts to pass through along with water.

The team discovered that a layer of epoxy raisin on either side of the sieve could prevent the expansion of the holes by restricting swelling. This stops the flow of salt molecules through the membrane. The scientists can even tune the amount of salt they want to let pass. Dr. Nair said, “Water molecules can go through individually, but sodium chloride cannot. It always needs the help of the water molecules. The size of the shell of water around the salt is larger than the channel size, so it cannot go through.”

Current desalination processes use polymer-based membranes, and this is the first time a demonstration has been shown of a technology where the size of the pores can be controlled. The technology is yet to be compared with the state of the art desalination methods available in the market. The durability of the membranes also needs to be demonstrated, showing salts and other biological materials do not affect the performance. A lot more work is required before the membranes can be manufactured inexpensively at a commercial scale.