Elon Musk has recently shared Tesla’s ambitious plan to roll out the next generation of electric vehicles, including a more affordable model, by late 2025. This disclosure follows Tesla’s introduction of the “Unboxed Process” during the 2023 Investor Day, a novel manufacturing system aiming to enhance efficiency and reduce costs in electric car production.

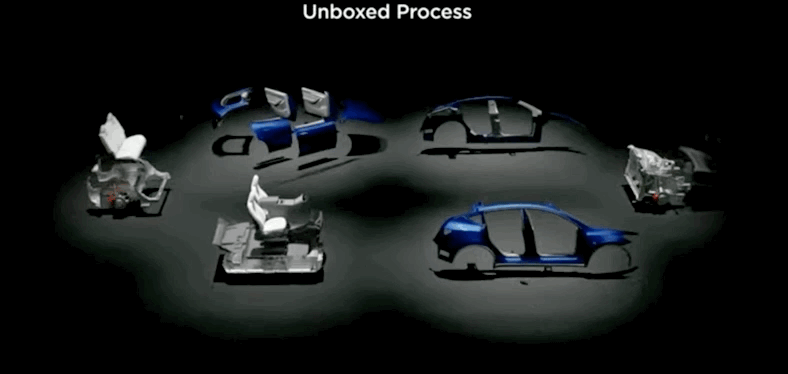

Tesla’s innovative “Unboxed Process” departs from the conventional car manufacturing model. CEO Elon Musk envisions a system where different vehicle sections are worked on individually, only converging at a later, more finalized assembly stage. This approach promises a faster and more cost-effective manufacturing process, facilitating the production of more affordable electric vehicles.

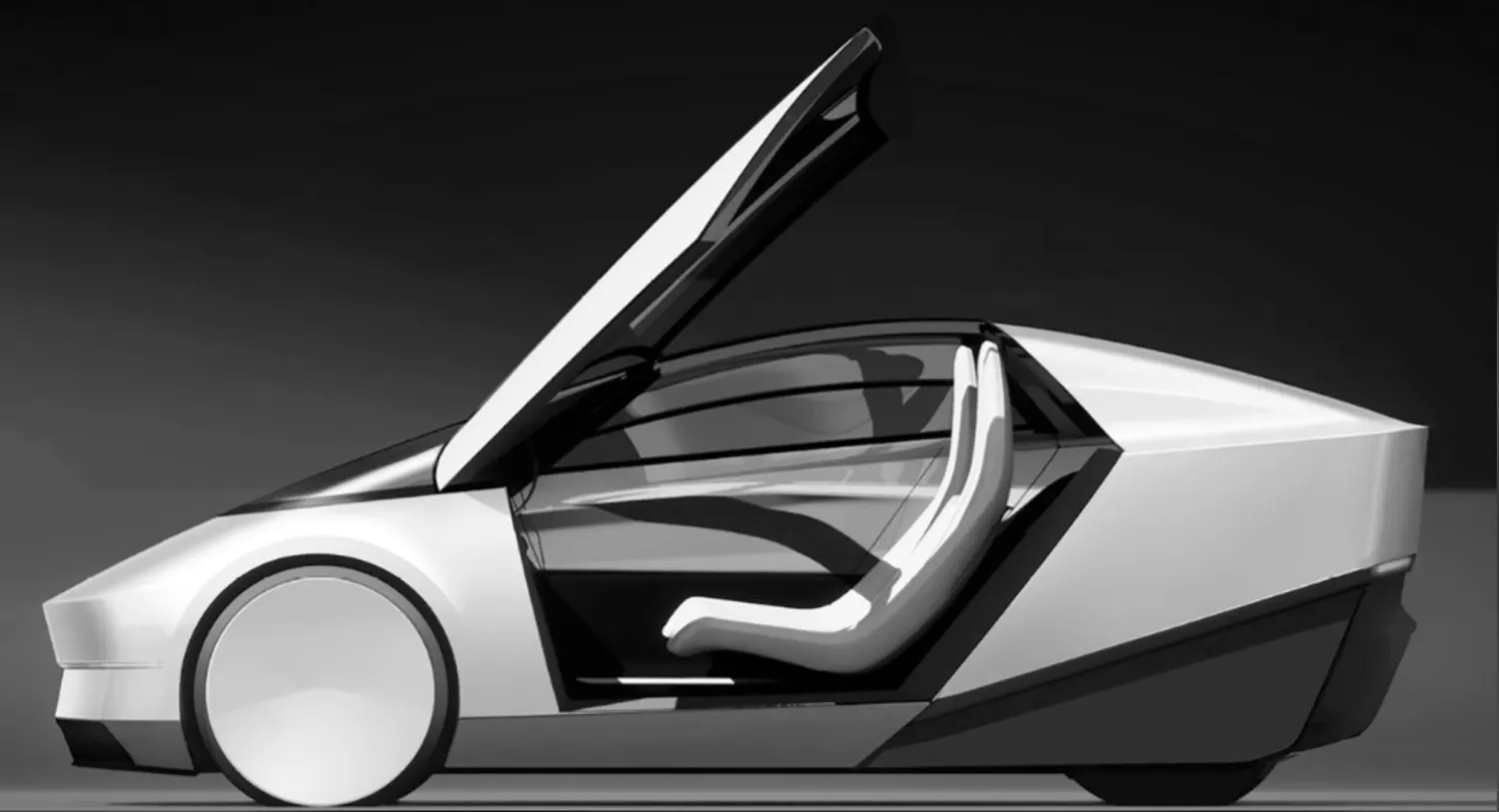

The upcoming next-generation Tesla vehicles, including a budget-friendly “$25,000 model” and a robotaxi, are slated to be the pioneers in adopting this groundbreaking manufacturing system. Musk, commenting on the timeline during the release of Tesla’s Q4 2023 earnings, tentatively set late 2025 as the target for production commencement. However, he cautioned that this timeline is subject to various factors and should be taken cautiously, addressing recent reports suggesting a mid-2025 production start.

Musk acknowledged the challenges associated with the production ramp-up, emphasizing the complexity of the task. As a strategic decision, Tesla plans to initiate production at Gigafactory Texas, leveraging the presence of its engineering team rather than opting for the upcoming Gigafactory Mexico. This move reflects Tesla’s commitment to navigating the intricacies of the production process with its experienced team.

Elon Musk’s disclosure sets a target of late 2025 for production, underscoring the company’s dedication to innovation and efficiency in the electric vehicle market.