A team of researchers from Dartmouth College has created a new type of smart ink. The ink can lead to a new style of 3D printed materials. The structures made from the smart ink can change shape and color. This adds more functionality to the created structure. The team wanted to create a new form of emerging technology from the existing one. The fans of 3D printing are hoping that 4D printing can offer a low-cost option for the critical parts in the categories like energy, biomechanics, and many others.

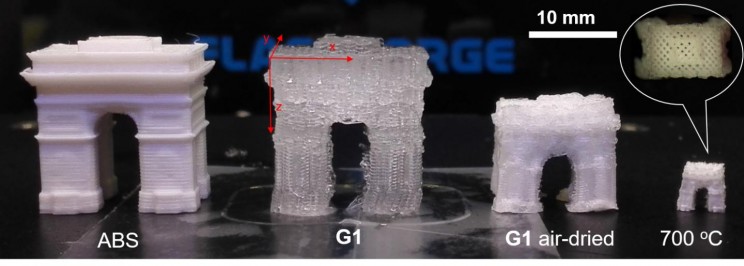

Chenfeng Ke, an assistant professor at Dartmouth said, “This technique gives life to 3D-printed objects. While many 3D-printed structures are just shapes that don’t reflect the molecular properties of the material, these inks bring functional molecules to the 3D printing world. We can now print smart objects for a variety of uses.” Mostly the inks used in 3D printing is the photo-curing resins which create hard, plastic objects or rigid structures. The researchers observed that these structures have random molecular architectures. The team developed a process which allows the designers to keep the ideal molecular alignment and the functions. The process they gave involved both pre and post-printing techniques. They could even shrink the object to 1% of their original size and with 10 times of the resolution.

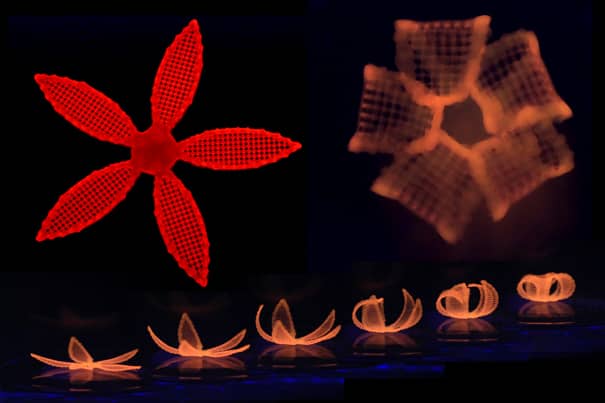

They used the fluorescent trackers and printed the objects which can change their color in response to some stimuli like the light. According to Ke, the smart ink can save a lot of time, money and other resources to researchers who are looking to leverage the technology for any discipline. He said, “This process can use a $1,000 printer to print what used to require a $100,000 printer. This technique is scalable, widely adaptable and can dramatically reduce costs.”

The smart ink is made up of a polymer-based vehicle which combines molecular systems into the printing gel. This system allows the molecules to swap their functions from nanoscale to the macroscale. The team gave a statement saying, “We believe this new approach will initiate the development of small molecule-based 3D printing materials and greatly accelerate the development of smart materials and devices beyond our current grasp that are capable of doing complex tasks in response to environmental stimuli.” The researchers are hoping that their smart ink can negate some of the problems faced during the current printing procedure.

Ke said, “This is something we’ve never seen before. Not only can we 3D print objects, we can tell the molecules in those objects to rearrange themselves at a level that is viewable by the naked eye after printing. This development could unleash the great potential for the development of smart materials.” Ke and his team said that they are still not anywhere near the 3D systems which can dynamically change the shape. But the current users can create a new type of macroscale 3D objects for things like the bone replacement or medicine delivery.