Chinese researchers have invented a novel method for 3D printing ceramics in mid-air that does not require any support structures. The new process can make ceramic pieces at nearly any angle, allowing for the creation of designs that were previously unattainable with regular 3D printing. Because of their high-temperature endurance, wear resistance, and structural stability, ceramics are widely employed in mechanical engineering, electronics, and aerospace. However, the brittleness and hardness of ceramics have made complicated pieces difficult to fabricate.

Additive manufacturing, or 3D printing, has provided a convenient and efficient way to produce complex ceramics with integrated structures and functions. In traditional 3D printing of ceramics, additional supporting structures are often necessary to prevent the collapse of unsupported parts, which affects printing efficiency and causes issues related to the removal of these supports.

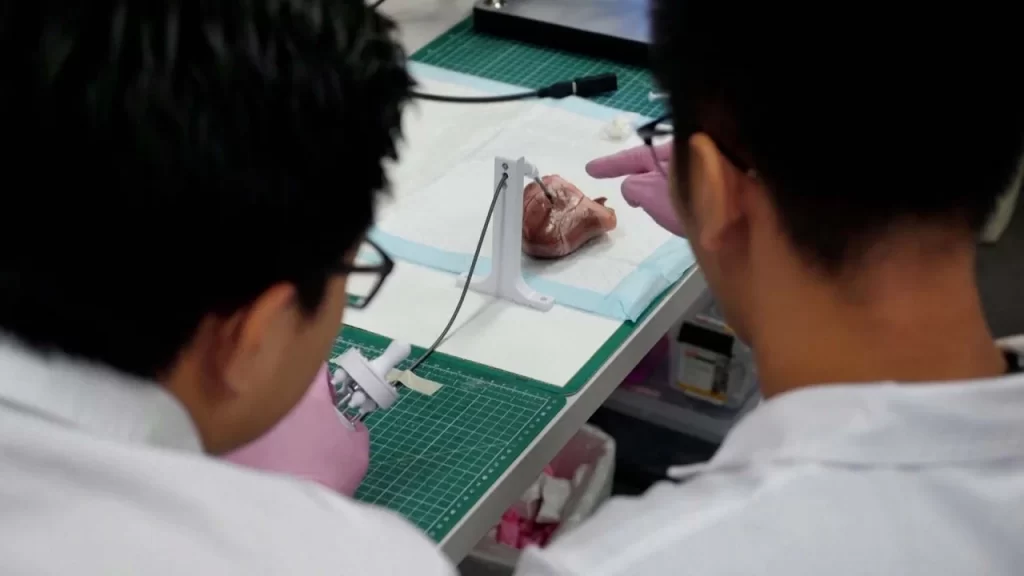

To solve these issues, Jiangnan University’s Professor Liu Ren and his colleagues created a new printing paste and better curing procedure that hardens the material quickly, increasing 3D printing efficiency for ceramics and removing the need for support structures. Their innovative technology can quickly harden multi-scale filaments ranging from 0.41mm (0.02 inch) to 3.5mm and manufacture ceramic structures such as torsion springs and cantilever structures. On April 25, their findings were published in the peer-reviewed journal Nature Communications.

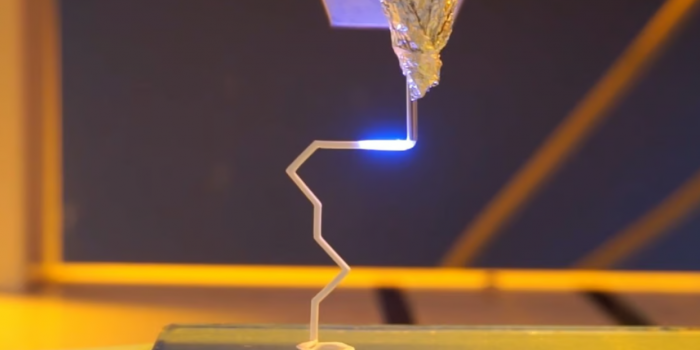

The new paste is a photosensitive ceramic slurry that rapidly solidifies and increases in strength upon exposure to near-infrared (NIR) light. With certain NIR radiation intensity, the material retains its shape in mid-air immediately after being extruded from the nozzle. The researchers demonstrated that their cutting-edge technique can allow printed ceramic curves to extend freely in space without support. They also showed that NIR light can achieve better results than ultraviolet (UV) light, commonly used for similar processes.

In video demonstrations, Liu and his team printed three-dimensional curved structures horizontally at a speed of 1mm per second. The resulting ceramics maintained their shape well and remained stable even during subsequent processes of sintering, or compacting and shaping under high temperatures. The technique was also used to create structures with sharp turns, such as torsion springs, although proper nozzle selection and laser positioning were essential to prevent their collapse or obstruction. The team also showed the ability to print mixed ceramics by using additives such as iron red and chromium green.