We all know people who go into a store, find something they like and then buy it in a few different colours so that it can be matched with different clothes. That might be a thing of the past as a new innovation from MIT in 3D printing allows investing in accessories with colour-changing ink.

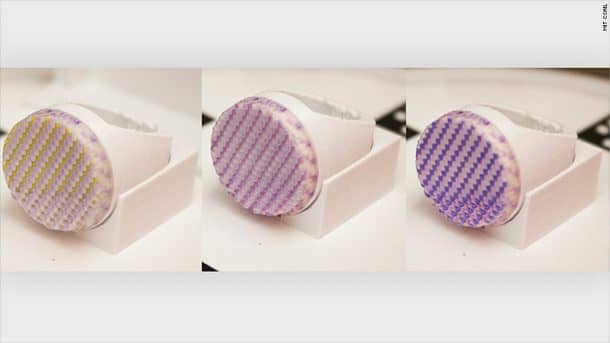

The team from MIT created an ink that allows owners to change the colour of the accessory on demand in a matter of minutes. The process is called ColorFab and allows a change of colour after the object has been fabricated.

“Largely speaking, people are consuming a lot more now than 20 years ago, and they’re creating a lot of waste,” says Stefanie Mueller, the X-Consortium Career Development Assistant Professor in the departments of Electrical Engineering and Computer Science and Mechanical Engineering. “By changing an object’s colour, you don’t have to create a whole new object every time.”

Many stores build their inventory by making the exact same style product in different colours. This ColorFab process is going to affect their sales. The project is currently focused on changing the colour of plastics and other common 3D printing materials. However, the researchers are hopeful that it will also extend to the textile industry one day and we will have colour-changing clothes.

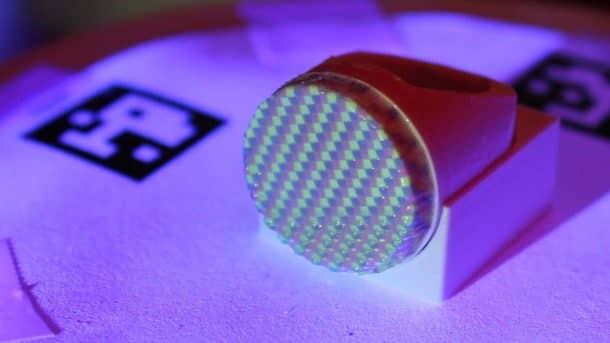

The MIT team made a hardware/software workflow to make the ink. They used the unique interface developed for ColorFab to allow users to upload 3D models, pick colour patterns and then print the object. The team uses UV light to activate the unique colours after the object has been printed.

How do they make the dye for the ink? The custom ink uses photoinitiators and light-adaptable dyes. The photoinitiator allows the base dye to harden up during the printing process and the photochromatic dyes bring out the main colour.

“Appearance adaptivity, in general, is always a superior feature to have, and we’ve seen many other kinds of adaptivity enabled with manufactured objects,” said Changxi Zheng, an associate professor at Columbia University who co-directs Columbia’s Computer Graphics Group. “This work is a true breakthrough in being able to change the colour of objects without repainting them.”

And for postdoc Parinya Punpongsanon (who co-authored the paper with Mueller), this could be one of the most economical ways to reduce waste when it comes to something as seemingly harmless as accessorizing. “This is the first 3-D-printable photochromic system that has a complete printing and recolouring process that’s relatively easy for users,” Punpongsanon said. “It’s a big step for 3-D printing to be able to dynamically update the printed object after fabrication in a cost-effective manner.”

You can watch it in the video below: