How many times have we thumped a shampoo bottle in our empty hand hoping for the residue to get out! Then we look inside the hole and see the heavy liquid sitting idly at the bottom of the bottle. As our last resort, we either fill it with some water or throw the bottle away.

Same happens with liquid soap, dishwashing liquid, and ketchup as they all are sold in bottles made of polypropylene (a kind of plastic) and are quite hard to empty. Those last dregs are stubborn and don’t feel like coming out.

Researchers from Ohio State University have come up with a solution: use of a nanotech lining that allows these heavy liquids to slide right off. The scientists claim that it will not only remove the vexation of thumping bottles in our palms but will also provide longevity and durability to the plastic.

How Does it Work?

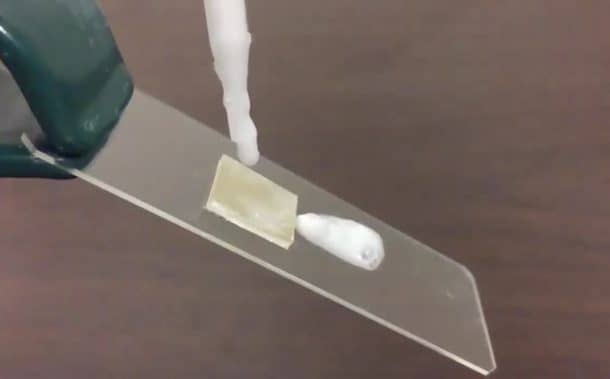

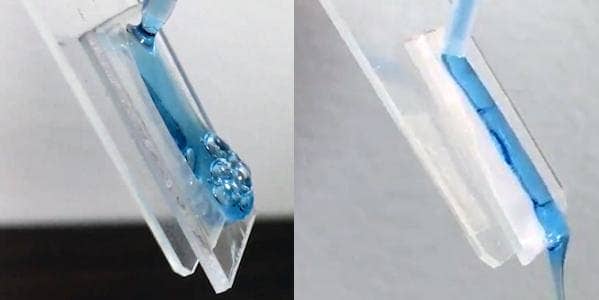

It adds a coating of a repellent buffer between the liquid and plastic so that soapy molecules don’t stick to the plastic. The coating consists of silica nanoparticles designed in microscopic y-shaped structures. Now, the branches of the “y” overhangs, its steep angles, and a cushion of air prevent the droplets from sticking to the plastic. This reduces the surface tension of the liquid, and consequently, shampoo and other such type of dregs slide off the surface smoothly.

Another technology using a hydrophobic coating was proposed in 2013 by Ultra-tech for industrial and waste management. But Ultra-tech’s technology had a drawback; its coating was composed of a combination of chemicals that were unsuitable for food containers. On the contrary, Ohio’s scientists have come up with a solution that is environment-friendly. It uses silica nanoparticles that are already being used in tap water in minute quantities and occurs naturally in many foods as well.

This technology has a wide range of uses. First of all, it can be used in recycling process. It won’t only make bottles clean but other materials too, such as the biomedical devices like catheters and other plastic devices that need to be clean all the time. The researchers have applied the coating to another kind of plastic, polycarbonate and used it in optical media, roofing, corrective lenses, smartphone cases, and various other devices.

The results have been very promising. For more detail, you can check out the research paper published in the journal Philosophical Transactions of the Royal Society.

Once the technology is implemented, you can say goodbye to the niggling vexation of getting dregs out of the bottle!