A little over a hundred years ago, we had no cars, airplanes, or even telephones. Once all those dreams became a reality, they became a vital part of our daily lives. When we got airplanes to fly thousands of feet above the skies and submarines to sink hundreds of feet below the surface of the ocean, we attempted the craziest of things while leaving no stone unturned. We made airplane carriers that drift above the waters and flying aircraft carriers that cruise the skies. A very secret one of these attempts was Habakkuk, the British military’s project.

The World War II was a time of crisis for the entire world when the strongest of countries collided, while many of the smaller ones just trailed behind, being one’s ally or the others’. Weapon and vessel manufacturing was at peak and resources were crucial as steel was running out quick. When the British ships attempted to cross the North Atlantic, the German U-boats intercepted and sank them to their death. The only way to protect these ships was to make use of the airplanes, but even they could not be deployed mid-ocean. Then arose the need for enormous aircraft carriers but they required massive amounts of steel that was just not available. The aircraft flying over the oceans needed to refuel while saving the resources used for overtaxing.

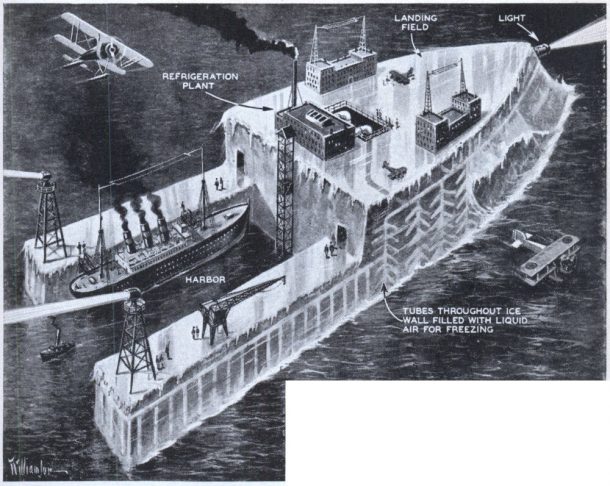

At that time, Geoffery Pyke, a British scientist, suggested to make an aircraft carrier out of ice. It sounded simple enough because ice is hard, does not sink, and is simple and easy to repair. Pyke was an advisor to Lord Mountbatten who then made Winston Churchill believe that ice could be their trump card. Then began the construction of the outrageous project known as “Habakkuk” by cutting a piece out of a huge arctic iceberg. The leveled surface of the iceberg served as a landing platform, and a hollow center was used as a shelter of the aircraft.

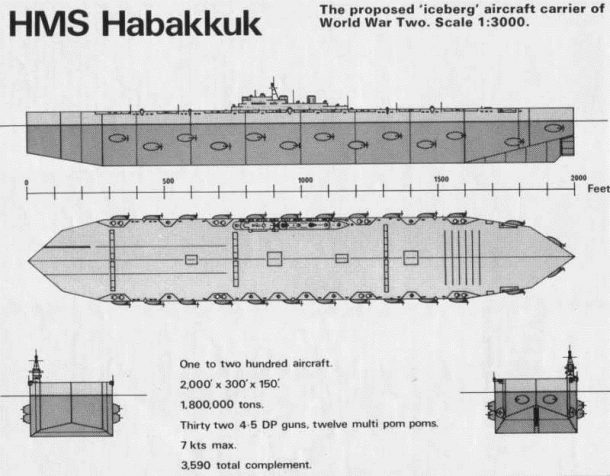

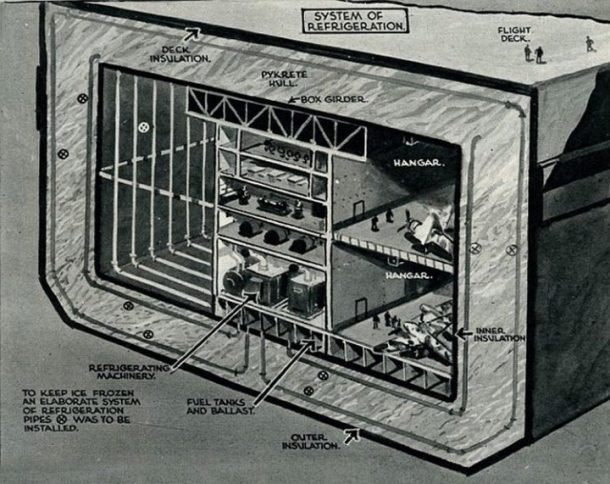

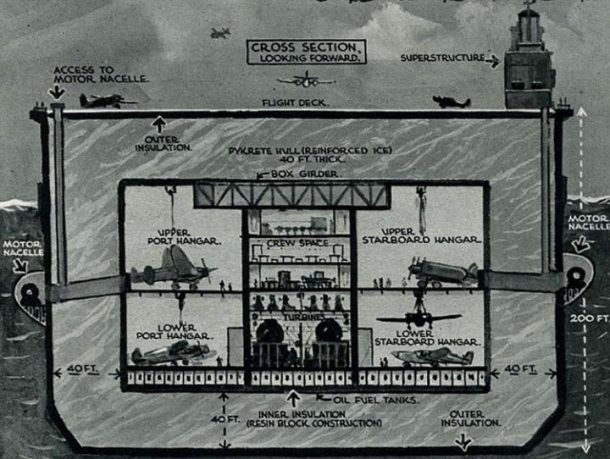

The ship was designed to be 2,000-feet long and 300-feet wide. The 2-million-ton ship was to have a 40-feet thick torpedo-proof hull equipped with 40 dual-barreled turrets and lots of anti-aircraft guns. The airstrip had enough space for 150 twin-engine bomber or fighter jets. To deal with the melting ice, a complex pipe network was to run through the entire ship that had chilled refrigerant pumping through it.

The first prototype was built on Patricia Lake in the Canadian Rockies that was only 60-feet long and weighed 1,000 tons. It was kept cool throughout the summers using a 1 hp refrigeration system, but that was not the end of problems. The brittle ice of the ship began to sag under its massive weight, so two researchers at the Polytechnic Institute of Brooklyn, New York found the solution. Water mixed with wood pulp or sawdust made ice about fourteen times stronger than the regular one, and it was even tougher than the concrete. This wood pulp ice could resist compression, chipping, and even bullets.

It became even more convenient because the ice was not that much brittle as before. They were able to cast it into shapes just like metal or machine it like wood. It even resisted melting by forming an outer insulating shell of wood pulp. The material was given the name pykrete to honor the genius of Pyke. Churchill made several demonstrations of the brilliance of the material at resisting bullets that didn’t even melt in Pykerete warm water, getting amazed himself at every occasion.

Once pykrete proved its capabilities, the designs and plans for the construction of Habakkuk were made even quicker. It was determined that each of the ships would require 300,000 tons of wood pulp, 25,000 tons of fibreboard insulation, 35,000 tons of timber, and 10,000 tons of steel that brought a cost estimate of £700,000. Once construction began, it became clear that more steel would be required, and insulation must be improved. There were problems with steering, and it could move at the top speed of 6 knots only, too slow for the Navy. Not to mention that the costs spiked up to £2.5 million that equates to £100 million today.

Steel was not the only material that was short. Being a very important manufacturing material, wood supplies were quite short too. If the Navy would have built even one Habakkuk, paper production must have gone down the drain. The time and human resources required to build the complex ship and keeping it cool were not available to any of the Allies.

All the constraints together killed the Project Habakkuk, and the Navy ended up making airfields in the Azores to hunt down the German U-boats. They also made the bigger fuel tanks on the aircraft to increase the patrol time.

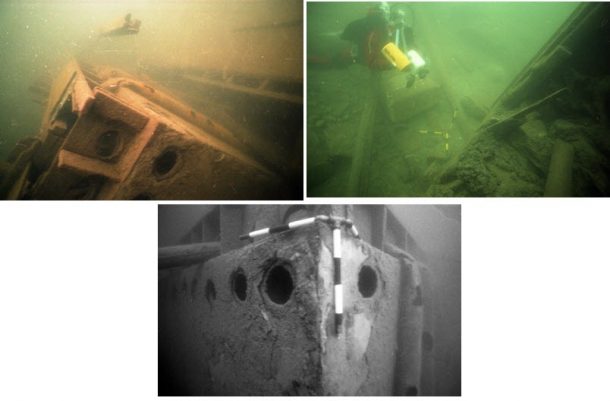

The remains of the secret project Habakkuk sank to the bottom of Patricia Lake in Alberta, Canada. The wooden hull, the cold air ductwork, and a huge mass of bitumen were found covered in an underwater plaque in a 1985 diving expedition to the site.

Do you think that this idea of an ice ship is feasible in today’s world? Share your thoughts by commenting below.

Today, think instead of a rocket launch/landing platform. Parts are brought out, assembled and raised. When fueling begins, it’s evacuated like any launch site, and cleared for a booster coming in to land. The platform has barely enough speed to mostly avoid weather, since most rockets want to launch from near the equator, there’s not much cyclonic weather there.

A dozen platform around the world allow boosters to come down, downrange rather than having to fly back (SpaceX boosters sometimes can make it back to launch site, but often they need the ship downrange)

See also mobile offshore base, studied by the DoD in the ’90s, made of linked platforms to allow the biggest logistics planes to land. Not at all a big high-value target, huh?