A new 3D printing process might bring innovation in the art of elaborate paper folding and origami. A team of researchers from Carnegie Mellon University (CMU) used the heat from a 3D-printer to make flat items which can fold themselves into different shapes when heated. The engineers used an inexpressive 3D-printer and used a ‘mistake’ in the 3D printing to create unusual shapes like roses, boats, and bunnies.

Lining Yao, assistant professor in CMU said that these objects could be considered a small step towards items like self-constructing furniture pieces or toys which will require heating to reach their final state. The researchers said that this technology could also be used to build emergency shelters quickly during rescue and relief operations. They can also use sun’s heat energy to take their final shape.

3D printing innovations have become very elaborate and significantly cheaper for the entry level 3D-printing. Self-folding materials cut down on overall production costs of 3D objects, allowing developers to replace noncritical parts quickly or to make simple prototypes with shapes that can approximate the final look. This can also be used to prepare molds for standard shaped objects and fibreglass products quickly.

Yao and her team say that the possibilities are endless. Yao said, “We wanted to see how self-assembly could be made more democratic — accessible to many users.” The team said that they used one of the cheap printers, FDM printers, available in the market. They made the most of one of the biggest complaints of ‘cheap’ printers: warpage. Yao said, “People hate warpage. But we’ve taken this disadvantage and turned it to our advantage.” FDM printers lay down the filament of melted thermoplastics. The material usually has residual stress and makes the plastics to contract and wrap as soon as they cool and relieve the stress.

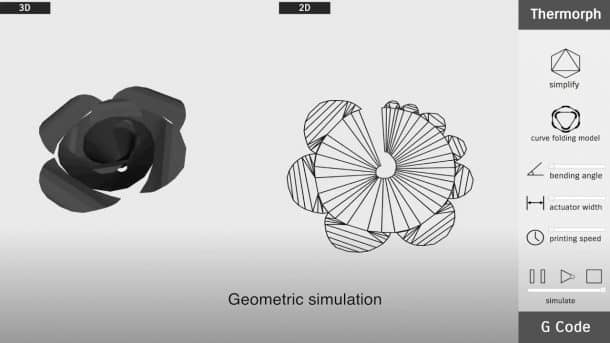

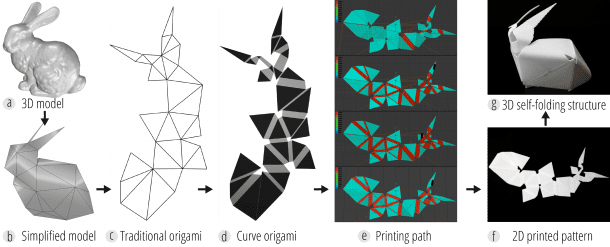

Byoungkwon An, a research affiliate, said, “The software is based on new curve-folding theory representing banding motions of curved area. The software based on this theory can compile any arbitrary 3-D mesh shape to an associated thermoplastic sheet in a few seconds without human intervention.” Yao added, “It’s hard to imagine this being done manually.” There is research being carried out on self-folding materials, but they include materials which are hard to find or use the processes which are too delicate to be used by an average 3D printer.

Yao and her team presented the research called “thermorphing” at the Conference on Human Factors in Computer Systems. Jianzhe Gu, an HCII research intern, said, “We believe the general algorithm and existing material systems should enable us to eventually make large, strong self-folding objects, such as chairs, boats or even satellites.”