A major milestone in sustainable food production has been achieved with the launch of the “world’s first farm to grow indoor, vertically farmed berries at scale.”

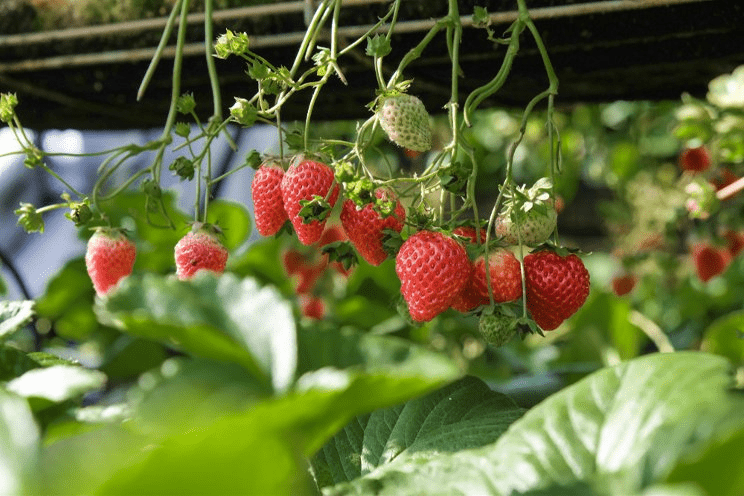

Located in Richmond, Virginia, this innovative farm known as Plenty Richmond Farm, a vertical farming facility, is set to produce over four million pounds (1.8 million kilograms) of strawberries annually. Unlike traditional farming, which is often constrained by seasons and environmental conditions, this farm will grow strawberries indoors in towering 30-foot (9-meter) vertical structures.

Remarkably, the farm operates on less than 40,000 square feet—an area smaller than a single acre—yet produces yields comparable to much larger traditional strawberry farms.

This technological leap forward is made possible through meticulous control of temperature, light, and humidity within 12 growing rooms. The farm’s highly regulated environment also improves pollination methods, making them more efficient than traditional bee pollination. By optimizing these conditions, the farm can ensure more uniform fruit production, minimizing waste while boosting yield.

Virginia Governor Glenn Youngkin lauded the project, stating, “Plenty’s farm will boost local agriculture production and drive economic development, all while diversifying against risks and protecting the environment.” The farm will also contribute to the local economy by offering fresh, sustainably grown strawberries from global giant Driscoll’s, available in stores by early 2025.

This shift to vertical farming marks a significant departure from previous methods, which mainly focused on leafy greens like lettuce. Now, this technology is proving its versatility by extending into fruit production. As Plenty CEO Arama Kukutai noted, “This farm is a model for the positive impact climate-agnostic agriculture can have, and proof that vertical farming can deliver the crop diversity, scaled and local production needed to future-proof the global food system.”

The Richmond facility represents the culmination of six years of research involving more than 200 trials to perfect the process of growing strawberries indoors with consistent, peak-season quality year-round. Driscoll’s, known for setting a high standard for berry quality, has partnered with Plenty to bring this innovative project to life. “We’re excited to join forces to consistently deliver an ultra-premium Driscoll’s strawberry year-round,” Kukutai added.

Behind this farm is an international team of researchers from institutions such as The University of Queensland, Macquarie University, and Wageningen University. These scientists have developed methods to grow crops in stacked indoor layers, which has dramatically reduced the farm’s environmental footprint. The controlled environment uses 97% less land and up to 90% less water compared to conventional farming while eliminating pesticide use and lowering the risk of crop pathogens.

Paul Gauthier, a professor at the University of Queensland, emphasized the potential of vertical farming, stating, “Vertical farms grow crops indoors in stacked layers and provide consistent yield and crop quality but they use a tremendous amount of costly energy for light and airflow.” Gauthier further explained how dynamic lighting systems could enhance the energy efficiency of vertical farming. He also highlighted his success in dramatically increasing strawberry yields: “I multiplied the strawberry yield by three by modifying the environment and pushing them to the limit.”

In terms of environmental sustainability, vertical farming offers a promising alternative to traditional methods. Gauthier argued for recognizing controlled environment agriculture as its own distinct scientific discipline, noting that global food production will need to increase by 70% by 2050 to meet demand. Vertical farming, he believes, is an essential tool in achieving this goal.

The research supporting this effort has been published in Frontiers in Science.

Source: The University of Queensland, Plenty, PR Newswire