Wilson has officially introduced the world’s first 3D-printed airless basketball prototype. The innovative design was first seen in Houston Rockets forward KJ Martin’s hands during his second slam in this year’s Slam Dunk Contest, demonstrating the ball’s real-life capability.

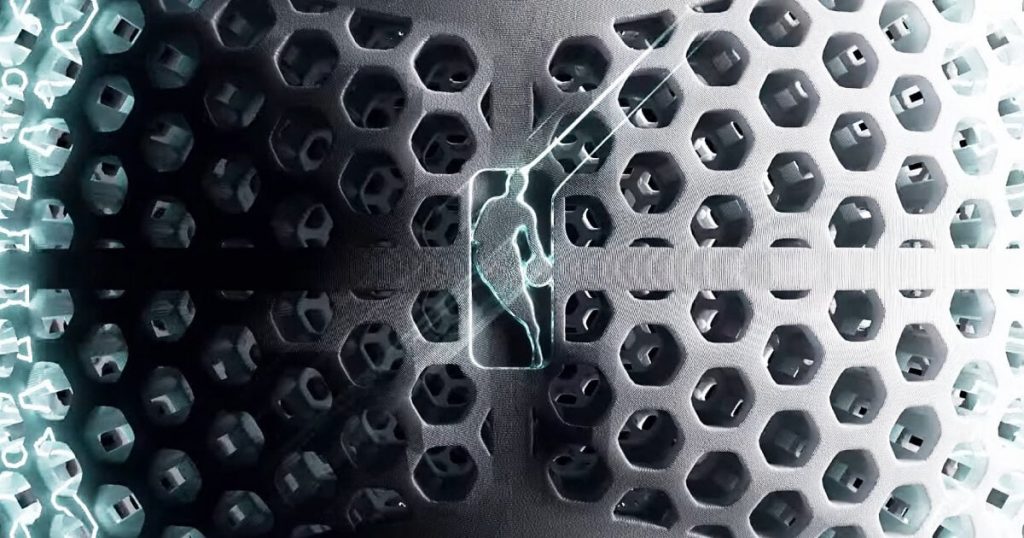

Wilson is looking into improving sports equipment with minimal maintenance and new technologies such as 3D printing, so the black-dyed, hexagonal-dotted basketball rebounds flawlessly from and to the player’s hand and the floor. Wilson’s 3D-printed airless basketball prototype eliminates the need to inflate the ball periodically.

“This is a ball unlike anything we’ve ever seen designed to play like the basketballs we’ve always known,” says Wilson.

Wilson’s goal was to create a basketball that looked like a basketball, felt like a basketball, and performed like a basketball. They also considered the player the team believed helped actualize the prototype since if a player didn’t appreciate how an airless basketball felt and worked, the production wouldn’t be greenlit.

To imitate the bounce of a typical basketball, the design team used a 3D-printed lattice structure using research-grade materials. The ball’s surface is encircled with microscopic hexagonal holes that allow air to move through, assisting the spring readily.

In addition, the airless prototype’s ribs include the characteristic seam structure of a normal basketball, as well as eight panel-like lobes. Wilson sees this latest breakthrough as a nudge to the corporation to create similar design features for other ball-related sports.

Wilson Labs completed the project in collaboration with General Lattice, which provided computational design services, DyeMansion for color and finishing, and EOS for additive manufacturing. EOS noted that working with Wilson on a 3D-printed basketball was a break from their regular venture because they often work with aerospace, automotive, and medical companies for 3D prints.

However, EOS believed they could assist Wilson in bringing the airless basketball to life.

While the Wilson Airless has been demonstrated to be playable, nearly matching the performance specifications of a regulation basketball in terms of weight, size, and bounce, it is still in the prototype stage. According to the company, there’s still work to be done before the 3D-printed airless basketball hits commercial stores and basketball courts,

However, the company is holding onto the prospect of making such an item and hopefully commercializing it.