For the laymen, it more of the same thing. But for an engineer and a student of fluid mechanics, the minute difference can be of grave consequences.

Pipes:

Pipes can be used to transport fluids like water, oil, and same is the case with tubes. But the major difference is the capacity or the inside diameter. For an ASME/ANSI B 36.10 Welded and Seamless Wrought Steel Pipe, the inside diameter – ID – of an NPS 2 inches pipe with schedule 40 is 2.067″ and for schedule 80 is 1.939″. As a quick recap, the schedule number on pipe products refers to the thickness of the wall of the pipe. The greater the number, the thicker the wall thickness becomes.

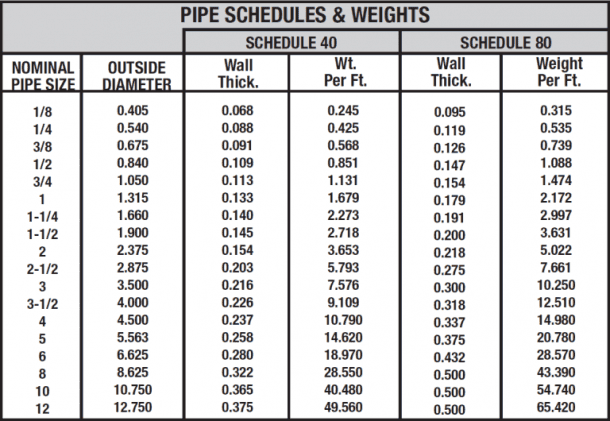

The schedule and the actual thickness of a pipe vary with the size of the pipe. Schedule and thickness are usually related to each other as shown below:

Since the outside diameter of a single pipe size is kept constant, the inside diameter changes as per the “schedule.” For a pipe, the inside diameter is close to 2″ and the outside diameter is 2.375″ for both schedules.

When compared to tubes, the tolerances are looser, and pipes are often less expensive to manufacture.

Tubes:

The nominal dimensions of tubes are referred to the outside diameter and taking Copper Tubes ASTM B88 as an example, the outside diameter of a 2″ pipe is 2.125″, relatively close to 2″.

The inside diameter of a tube is related to its thickness, which is specified as a gauge. For Copper Tubes – ASTM B88 the wall thickness of 0.083″ of a 2″ pipe is gauge 14.

Tubes have higher tolerances when compared to pipes and are often more expensive to produce than pipes.

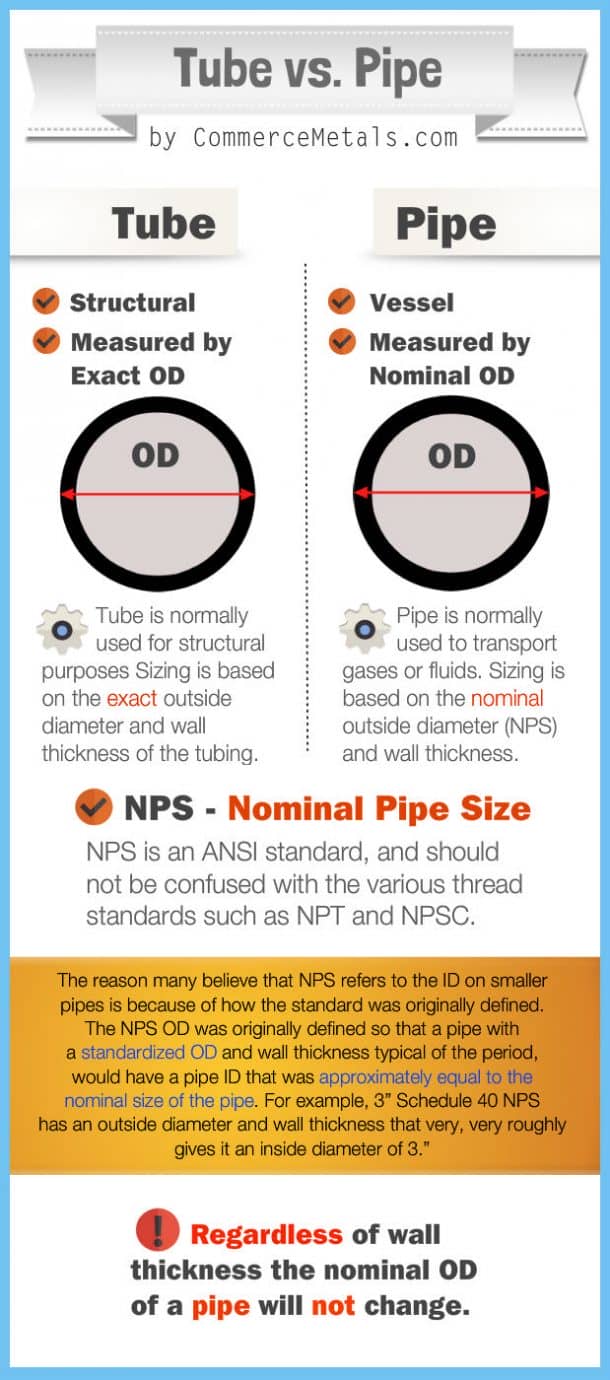

Below is a cool infographic that further highlights the differences between pipes and tubes.

Informative.

Useful

Very informative for Engineers & Technicians.